Infrared thermal imaging low-temperature economizer leakage detection device

A low-temperature economizer and infrared thermal imaging technology, applied in the application of light to test fluid tightness, etc., can solve the problems of long leak detection cycle and inaccurate positioning, and achieve the effects of sensitive response, precise positioning, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

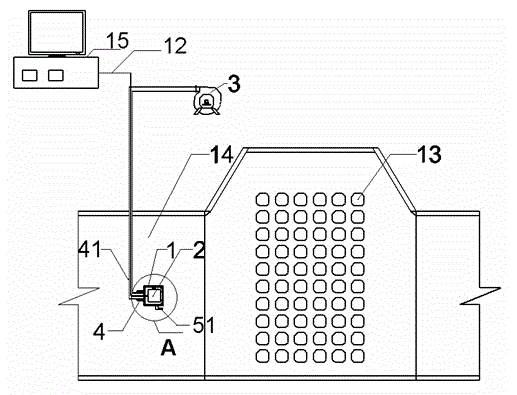

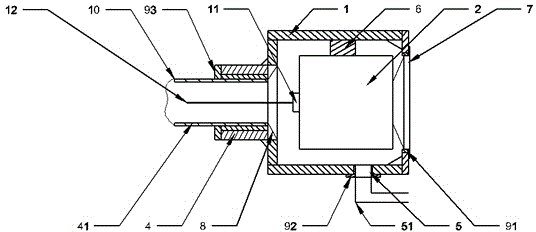

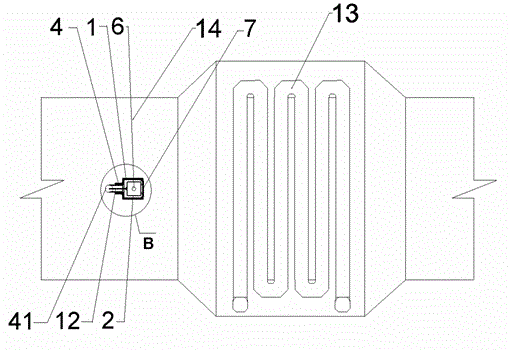

[0029] Such as Figure 1 to Figure 4 As shown, the infrared thermal imaging low-temperature economizer leak detection device of the present invention includes a housing 1 and an infrared thermal imager 2 . Wherein, the casing 1 is provided with an air inlet 4 and an air outlet 5; the infrared thermal imager 2 is fixedly installed in the cavity of the casing 1 through a fastener 6, and a through hole is opened on the wall of the casing 1, and the infrared thermal imager The lens 7 of 2 is installed in this through hole.

[0030] As a preferred embodiment, the present invention also includes a cooling fan 3 placed outside the flue 14 . Such as figure 1 , 2 , 4, the cooling fan 3 is connected to one end of the air inlet duct 41, and the other end of the air inlet duct 41 is connected to the air inlet 4 of the housing 1 after passing through the flue 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com