Multi-core coaxial cable

A technology of coaxial cable and coaxial cable, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of cable insulation damage, insulation aging and deterioration, mechanical damage, etc., and achieve strong resistance to disconnection, excellent waterproof performance, and conductive good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

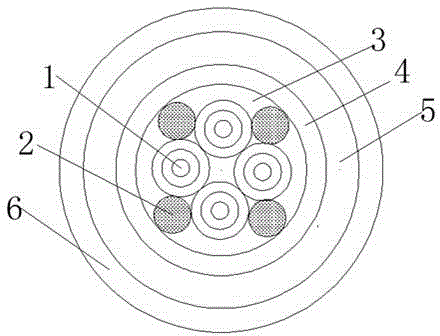

[0010] Such as figure 1 As shown, the present invention is realized by adopting the following technical solutions: a multi-core coaxial cable, which is composed of a coaxial core 1, a tape layer 3, a galvanized aluminum alloy wire shielding layer 4, and a waterproof layer 6. .

[0011] Wherein, the coaxial core 1 is composed of an inner conductor, an inner skin layer, and an outer conductor of a bare copper wire that are sequentially wrapped;

[0012] The tape layer 3 of the present invention is wrapped with four reinforcing members 2 inside, and the reinforcing members 2 are circumscribed to the adjacent coaxial core 1;

[0013] The galvanized aluminum alloy wire shielding layer 4 of the present invention is provided with a double-layer water barrier layer 5 between the waterproof layer 6;

[0014] The galvanized aluminum alloy wire shielding layer 4 of the present invention is braided by steel-clad steel wires with a braiding density of 45%.

[0015] As a preferred solution of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com