A wiring method of a triangular three-dimensional coil core on-load capacity-adjusting voltage-regulating transformer

A three-dimensional wound iron core, voltage regulating transformer technology, applied in the direction of transformers, variable transformers, transformer/inductor coils/windings/connections, etc., can solve the problems of unbalanced three-phase power supply, inconvenient maintenance, large line loss, etc. To achieve the effect of beautiful wiring, convenient disassembly and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

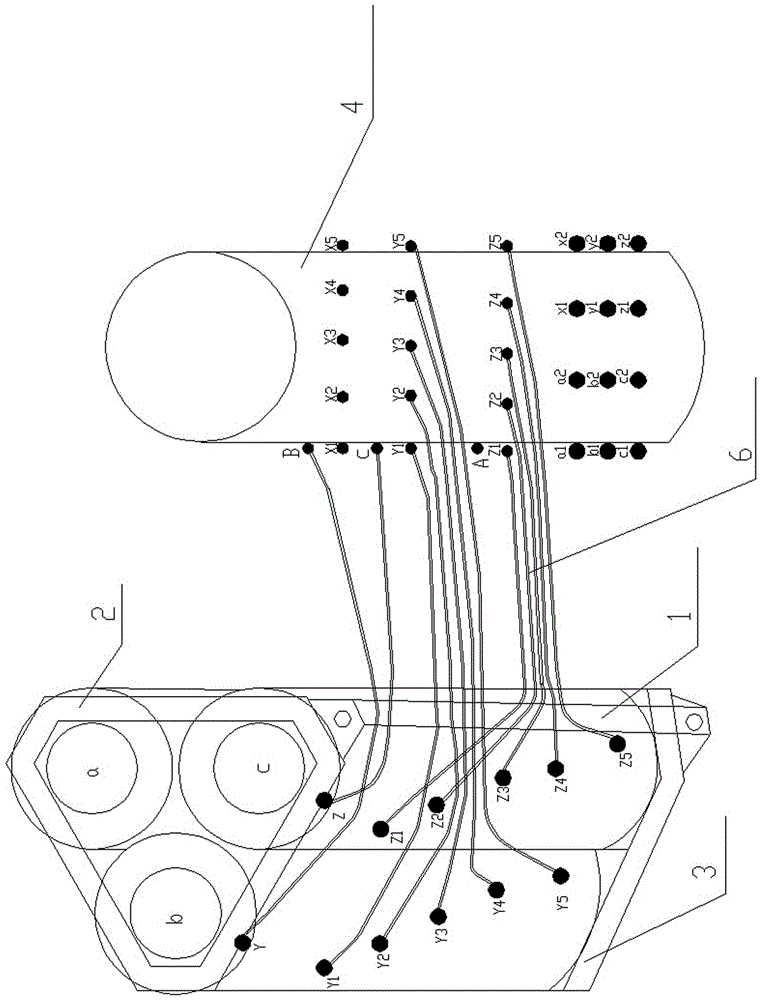

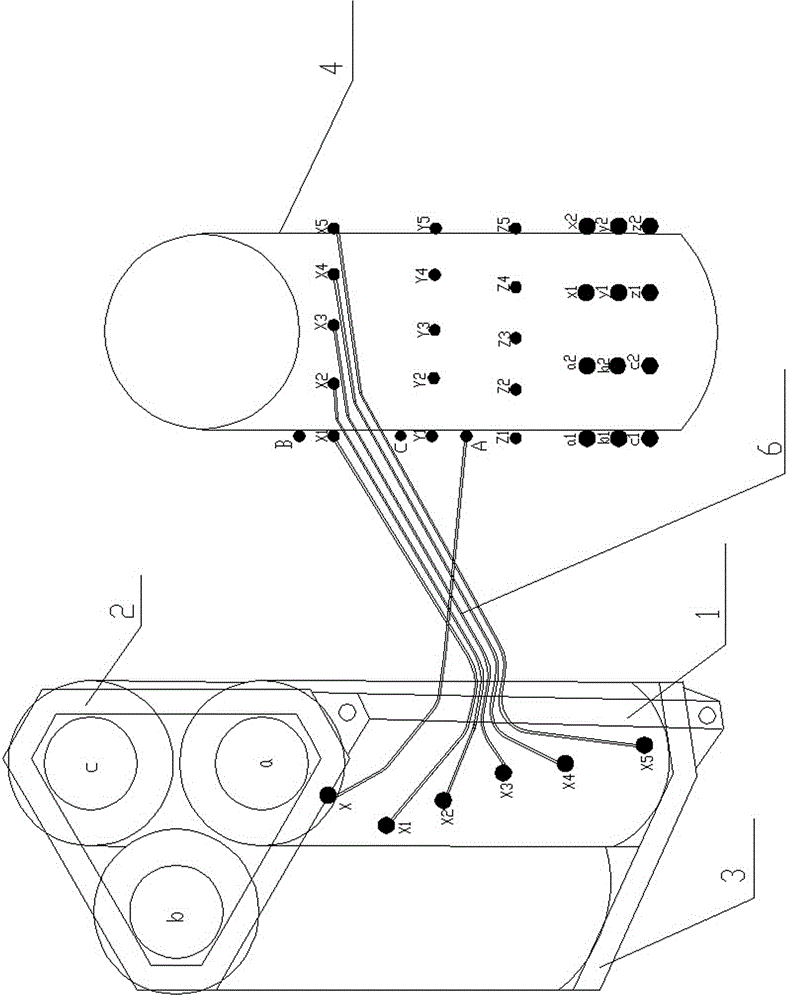

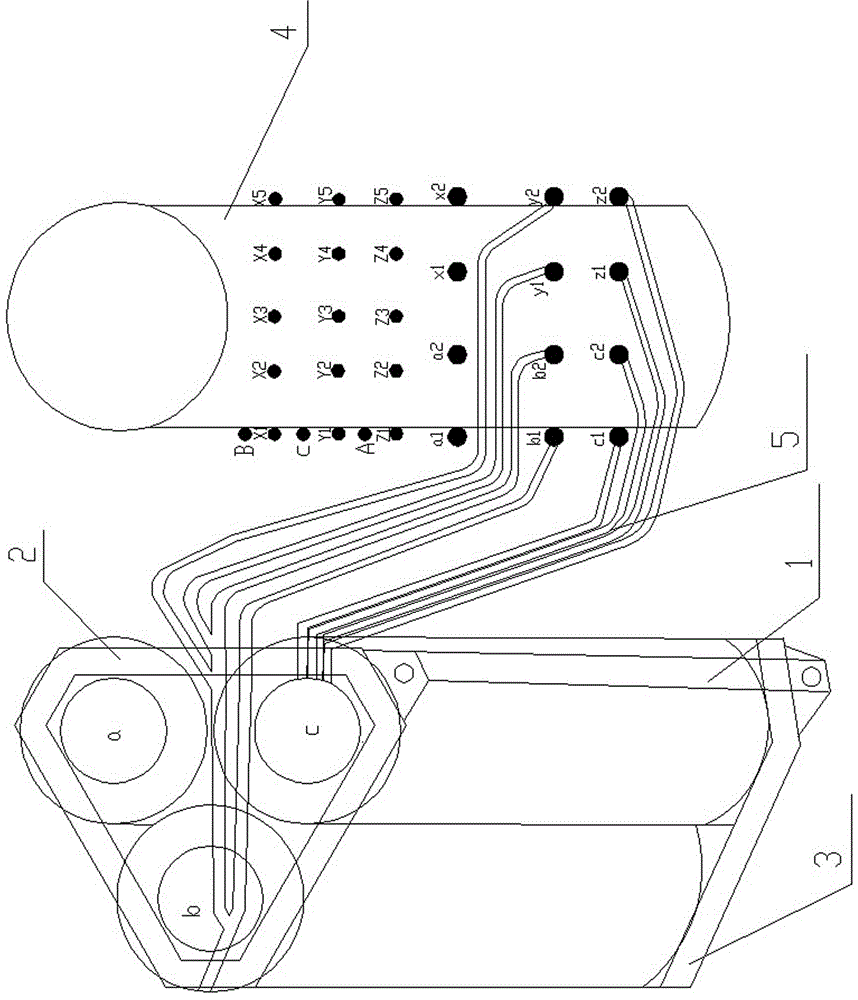

[0015] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a triangular three-dimensional winding core on-load capacity-adjusting voltage-regulating transformer routing method, which includes a triangular three-dimensional winding core, on-load capacity-adjusting and voltage-regulating tap changer 4, and high-voltage leads 6 and The low-voltage lead wire 5, the triangular three-dimensional winding core and the on-load capacity and voltage regulating tap changer 4 are placed in the same transformer housing, and a clamping piece is provided on the triangular three-dimensional winding core, and the clamping piece includes a wooden clip Part 1, upper iron clip 2 and lower iron clip 3, the transformer housing above the triangular three-dimensional coiled iron core is provided with an O-phase porcelain bottle, and a high-voltage wiring is provided on the on-load capacity regulating tap changer 4 Terminals and low-voltage connection terminals, the high-voltage leads 6 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com