Method for matching lithium ion power batteries for automobiles

A power battery pack and power battery technology, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve problems such as unsatisfactory use performance, and achieve the effect of long service life and stable energy output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of a lithium-ion power battery assembly method for automobiles involved in the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

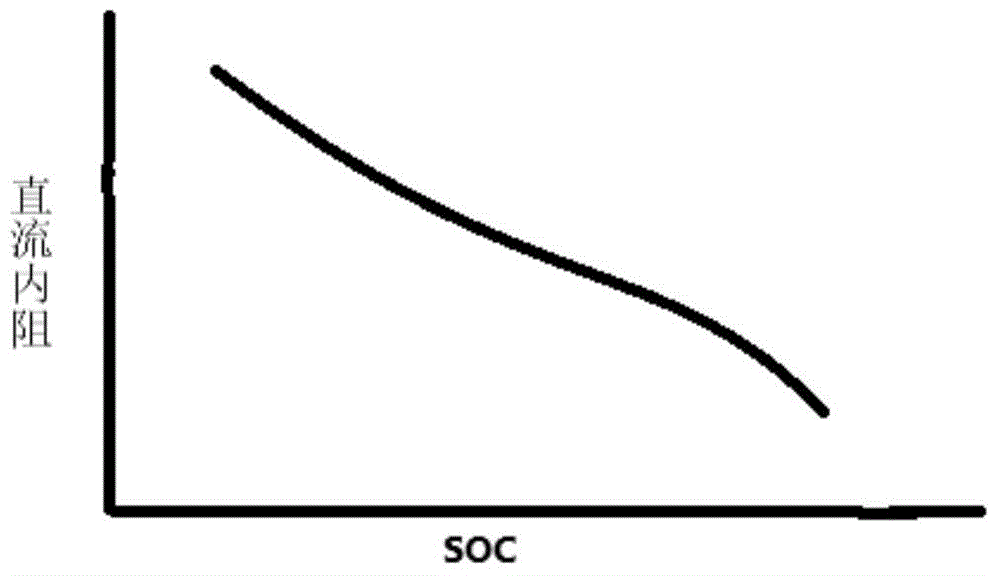

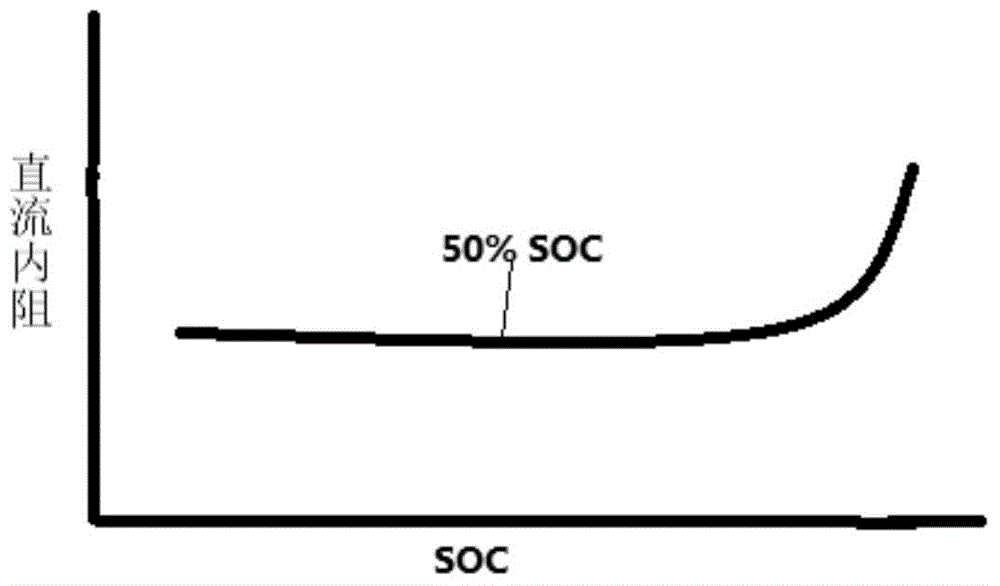

[0031] First of all, the method involved in the present invention considers that the DC internal resistance of the battery has a more direct and intuitive influence on the performance of the battery for the application of the power storage unit of the vehicle. Secondly, the requirement of the vehicle power for the energy storage unit is mainly the power request, so the total energy of the battery pack has a direct relationship with the cruising range of the vehicle. Therefore, both parameters are reflected in the method involved in the present invention.

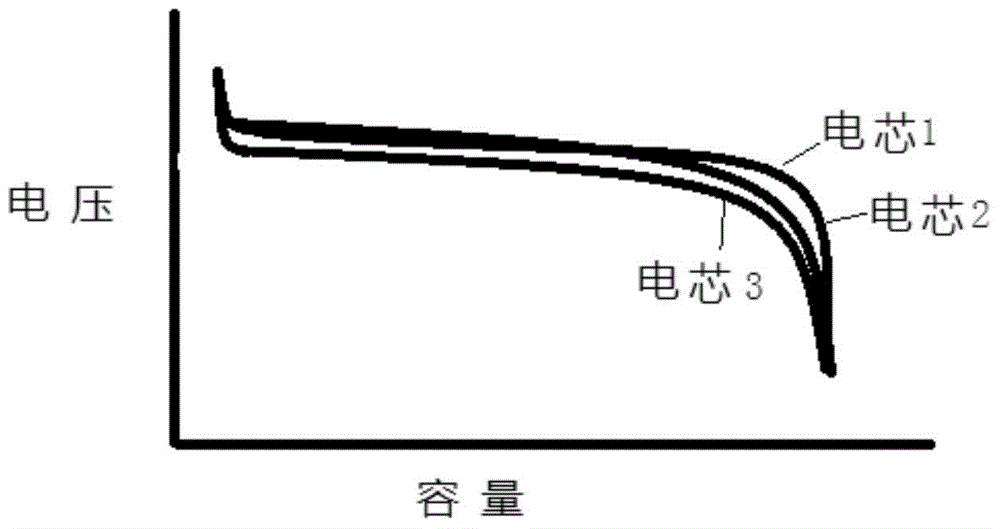

[0032] In addition, due to the differences among themselves, when the same type of battery releases the same capacity, its voltage platform may be different, so the total energy released when reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com