Method for condensing oxygen isotopes

An oxygen isotope and concentration technology, applied in the separation of different isotopic elements, separation methods, chemical instruments and methods, etc., can solve the complex problems of nitric oxide treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

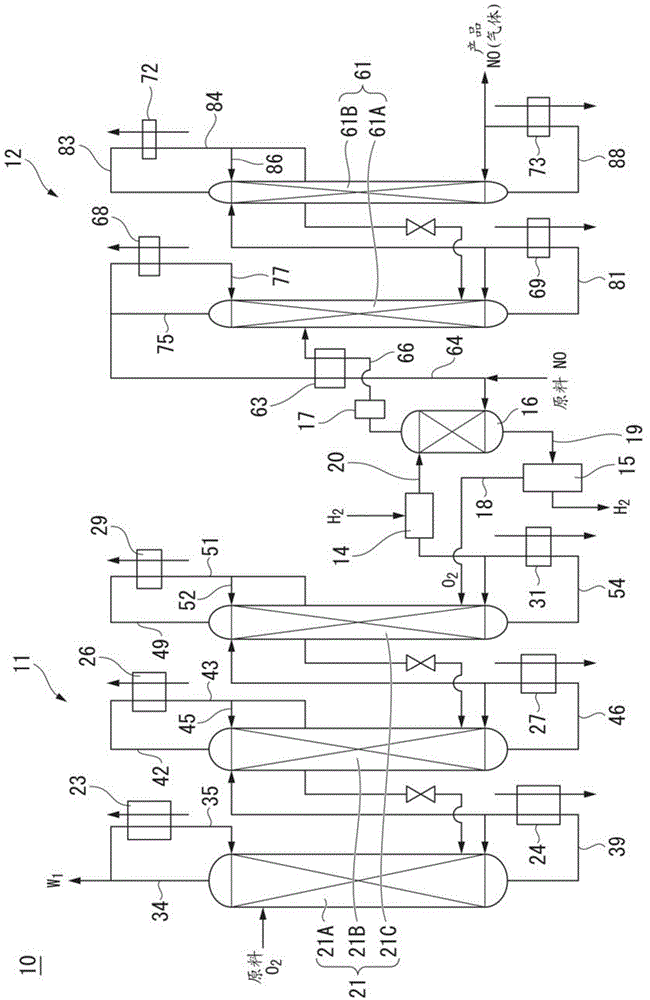

[0036] figure 1 It is a figure which schematically shows the schematic structure of the oxygen isotope enrichment apparatus used when carrying out the oxygen isotope enrichment method of 1st Embodiment of this invention.

[0037] First, refer to figure 1 , the oxygen isotope enrichment device 10 used when performing the oxygen isotope enrichment method of the first embodiment will be described.

[0038]The oxygen isotope enrichment device 10 of the first embodiment has a first distillation device 11, a second distillation device 12, a hydrogenation unit 14, a water splitting unit 15, a chemical exchange tower 16, a dehydration unit 17, an oxygen return path 18, and a water return path 19 and water supply path 20.

[0039] The first distillation unit 11 is the oxygen (O 2 ) is used as a device for distillation as a raw material, which has a first distillation column group 21, a first condenser 23, a first evaporator 24, a second condenser 26, a second evaporator 27, a third ...

no. 2 approach

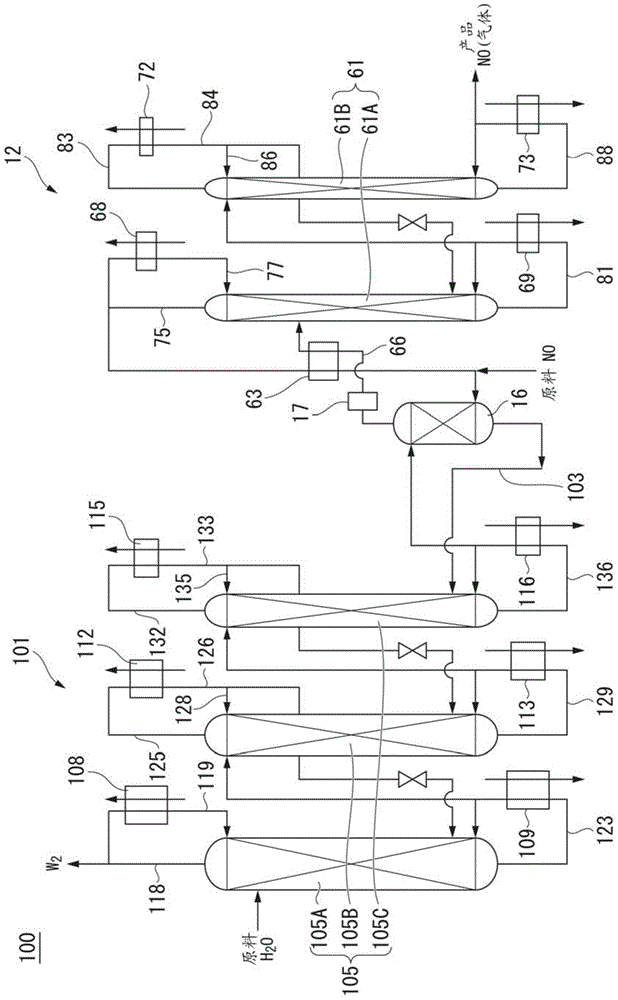

[0114] figure 2 It is a figure which schematically shows the schematic structure of the oxygen isotope enrichment apparatus used when carrying out the oxygen isotope enrichment method of 2nd Embodiment of this invention. exist figure 2 in, right with figure 1 The same structural parts of the oxygen isotope enrichment device 10 of the first embodiment shown are denoted by the same symbols.

[0115] First, refer to figure 2 , the oxygen isotope enrichment device 100 used when performing the oxygen isotope enrichment method of the second embodiment will be described.

[0116] Regarding the oxygen isotope enrichment apparatus 100 of the second embodiment, a first distillation apparatus 101 is provided instead of the first distillation apparatus 11 provided in the oxygen isotope enrichment apparatus 10 of the first embodiment, and constituent oxygen isotopes are removed from structural elements. The concentration device 10 is the same as the oxygen isotope enrichment device ...

Embodiment

[0152] (Example)

[0153] In the example, using figure 1 The oxygen isotope enrichment device 10 shown in the first embodiment concentrates the oxygen isotope ( 18 O and 17 O).

[0154] In the examples, nitric oxide (N 17 O) contained in 17 The O content is set to 10atom% or more, and the nitric oxide (N 18 O) contained in 18 The O content is set to 98 atom % or more.

[0155] In order to obtain nitric oxide (N 17 O), assuming that five tons of concentrated hydrogenated 17 O water, the process of constructing the enrichment method of oxygen isotopes.

[0156] Next, the method of enriching the oxygen isotope of the example will be described.

[0157] First, oxygen as a raw material is supplied to the first distillation column 21A (supply amount: 5500 Nm 3 / h), and use the first distillation column group 21 formed by connecting the first to third distillation columns 21A, 21B, and 21C in series to distill oxygen as a raw material to concentrate the oxygen isotope ( 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com