High capacity cathode active material

A cathode material and electrode technology, applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of expensive, long-term stability, reduced charge/discharge rate capability, increased battery cost and complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

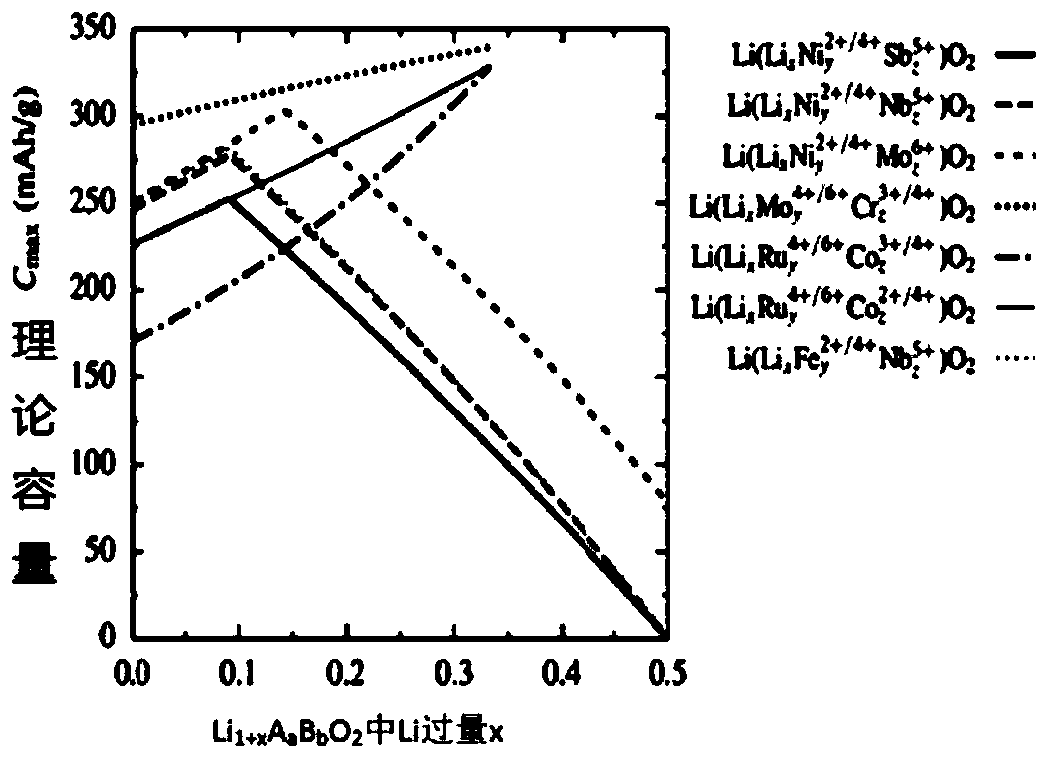

[0051] Li 1+x Mo 2x Cr 1-3x o 2 ,[0.15

[0052] In order to prepare Li 1+x Mo 2x Cr 1-3x o 2 , Li 2 CO 3 、MoO 2 and Cr 3 (OH) 2 (OOCCH 3 ) 7 used as a precursor. more than needed to synthesize Li 1+x Mo 2x Cr 1-3x o 2 , the stoichiometric excess of [02 CO 3 It is used to compensate possible Li loss in high temperature solid-state reaction. The precursor was dispersed into acetone and ball milled for 24 hours and dried overnight to prepare the precursor mixture. The mixture was sintered at 1050 °C under Ar gas for 15 h, and ground manually to obtain the final product.

[0053] Carbon coating can be applied 1) to prevent the dissolution of Mo and Cr, and 2) to reduce the particle size in the carbon coating treatment to increase the Li 1+ x Mo 2x Cr 1-3x o 2 cyclic performance, and 3) to improve the electronic conductivity of the compound. Sucrose (C 12 h 22 o 11 ) can be used as a carbon precursor, and with Li 1+x Mo 2x Cr 1-3x o 2 Mix ...

Embodiment 2

[0060] Li 1+x Ni (2-4x) / 3 m (1+x) / 3 o 2 ,[0.15

[0061] In order to prepare Li 1+x Ni (2-4x) / 3 m (1+x) / 3 o 2 [M=Sb or Nb], Li 2 CO 3 、NiCO 3 and Sb 2 o 5 (or Nb 2 o 5 ) were used as precursors. more than needed to synthesize Li 1+x Ni (2-4x) / 3 m (1+x) / 3 o 2 , the stoichiometric excess of [02 CO 3It is used to compensate possible Li loss in high temperature solid-state reaction. The precursor was dispersed into acetone and ball milled for 24 hours and dried overnight to prepare the precursor mixture. The mixture was heated at 800 °C in O 2 Sintering in air for 15 hours and grinding by hand to obtain the final product.

[0062] Carbon coating can be applied 1) to reduce particle size in carbon coating treatment to increase Li 1+x Ni (2-4x) / 3 m (1+x) / 3 o 2 [M=Sb or Nb] for cycling performance, and 2) to improve the electronic conductivity of the compound. Sucrose (C 12 h 22 o 11 ) can be used as a carbon precursor, and with Li 1+x...

Embodiment 3

[0065] Li 1+x Ni (3-5x) / 4 Mo (1+x) / 4 o 2 ,[0.15

[0066] In order to prepare Li 1+x Ni (3-5x) / 4 Mo (1+x) / 4 o 2 , Li 2 CO 3 、NiCO 3 and MoO 2 Can be used as a precursor. more than needed to synthesize Li 1+x Ni (3-5x) / 4 Mo (1+x) / 4 o 2 The stoichiometric excess of [02 CO 3 It is used to compensate possible Li loss in high temperature solid-state reaction. The precursor was dispersed into acetone and ball milled for 24 hours and dried overnight to prepare the precursor mixture. The mixture was heated at 800 °C in O 2 Sintering in air for 10 hours and grinding by hand to obtain the final product.

[0067] Carbon coating can be applied 1) to reduce particle size in carbon coating treatment to increase Li 1+x Ni (3-5x) / 4 Mo (1+x) / 4 o 2 cyclic performance, and 2) to improve the electronic conductivity of the compound. Sucrose (C 12 h 22 o 11 ) can be used as a carbon precursor, and with Li 1+x Ni (3-5x) / 4 Mo (1+x) / 4 o 2 Mix in a planetary ball mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com