Motorcycle frame rear body assembly welding fixture

A technology for welding fixtures and motorcycles, which is applied in the field of tooling and fixtures, can solve the problems of affecting the forming quality, low positioning accuracy, troublesome clamping and positioning, etc., and achieve the effects of saving fixture time, high precision, and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

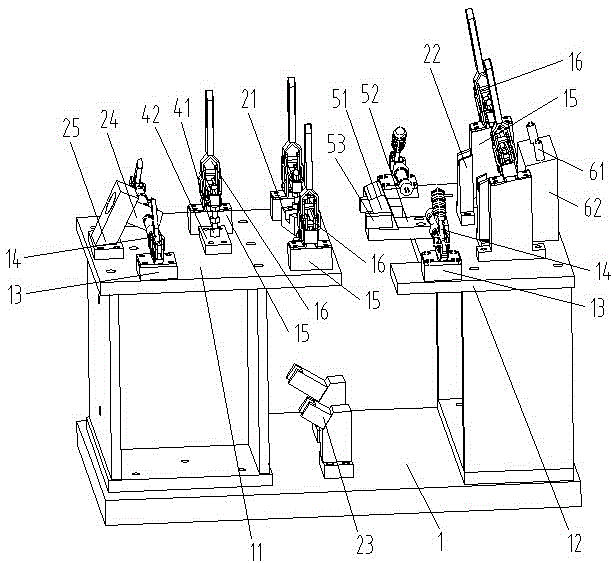

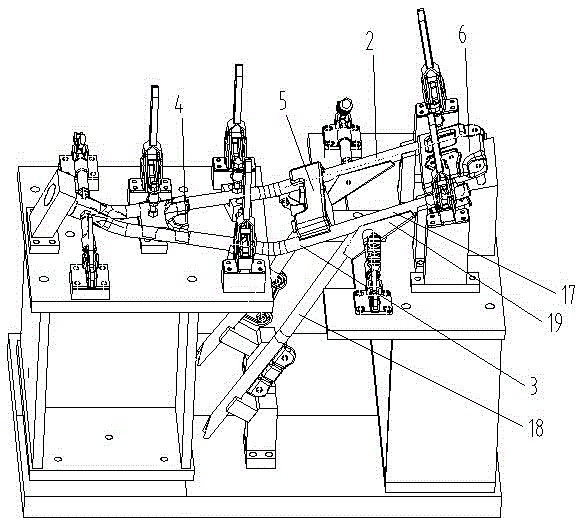

[0020] see figure 1 and figure 2 , the motorcycle frame rear body assembly welding jig of the present invention comprises a lower base plate 1, on which a right half body combination positioning mechanism, a left half body combination positioning mechanism, a fuel tank rear mounting bracket component positioning mechanism, and left and right connecting plates are arranged. The positioning mechanism and the seat cushion lock mounting bracket assembly positioning mechanism, the right half combined positioning mechanism and the left half combined positioning mechanism are symmetrically arranged relative to the length direction of the lower bottom plate. The upper front base plate 11 and the upper rear base plate 12 of a certain height higher than the lower base plate are respectively provided with the support structure on the front and rear sides of the lower base plate 1, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com