Machining method for stainless steel mobile phone rear cover

A technology for the back cover of a mobile phone and a processing method, which is applied in the directions of telephone communication, electrical components, branch equipment, etc., can solve the problems of reducing the service life and aesthetics of the mobile phone, the appearance is not beautiful and elegant, and the manufacturing cost is high, and achieves the appearance of metallic texture, increased Effect of metal surface area and manufacturing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

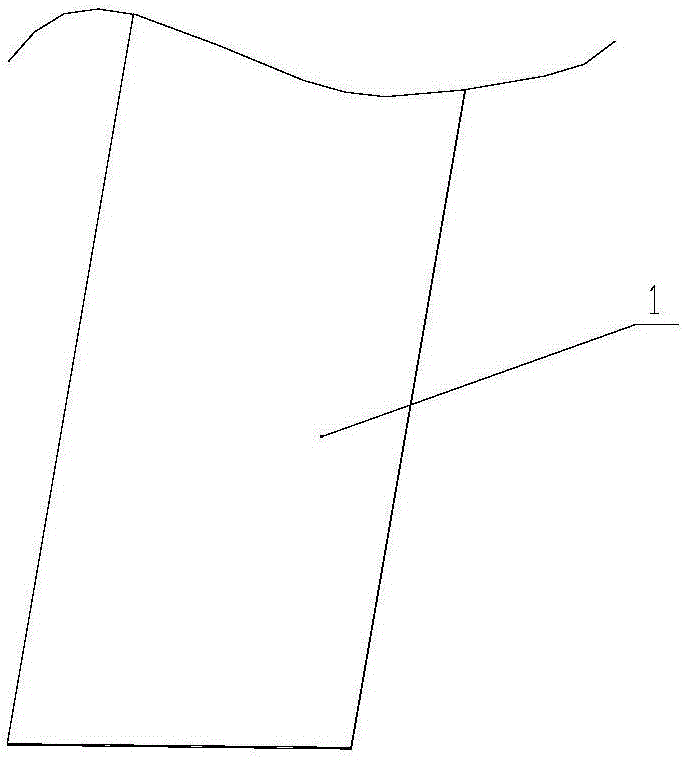

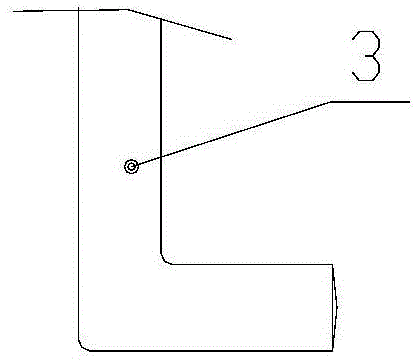

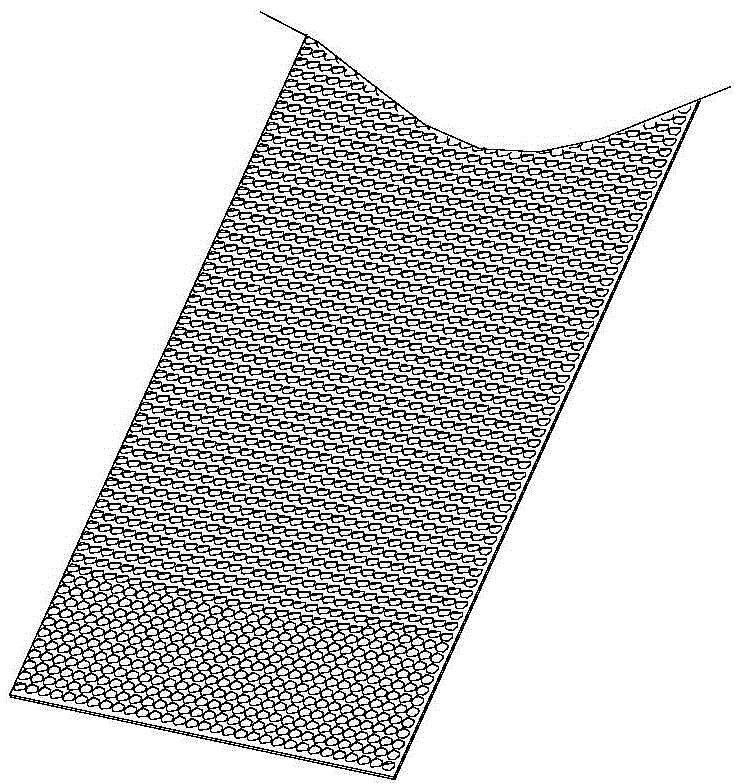

[0031] figure 1 It is a structural schematic diagram of the material tape of the mobile phone back cover provided by the present embodiment; figure 2 It is a structural schematic diagram of the finished product of the mobile phone back cover provided by this embodiment. A method for processing the back cover of a stainless steel mobile phone, the method at least includes the step of etching and reducing weight on the material belt 1 of the back cover of the mobile phone, which is used to reduce the weight of the back cover of the mobile phone and improve the bonding force of in-mold injection molding, wherein the mobile phone The material strip 1 of the back cover is made of 0.4-0.8mm stainless steel, the etching depth of the material strip 1 of the mobile phone back cover is 0.2-0.5mm, and the material thickness of the material strip 1 of the mobile phone back cover can be thicker or thicker according to actual needs. For thinner stainless steel materials, the etching depth...

Embodiment 2

[0043] This preferred embodiment discloses a method for processing the back cover of a stainless steel mobile phone, which is basically the same as the first preferred embodiment. The method at least includes the step of etching the material tape of the mobile phone back cover to reduce the weight of the mobile phone back cover and improve the bonding force of in-mold injection molding, wherein the material tape of the mobile phone back cover is selected as 0.4-0.8mm Made of stainless steel, the etching depth of the tape on the back cover of the mobile phone is 0.2-0.5mm.

[0044] The difference is that the weight reduction step of etching can be carried out before stamping, or after the rough machining or surface treatment of CNC machine tools, which can reduce the weight of the back cover of the mobile phone and improve the plasticity of the in-mold injection molding process. The bonding force with the back cover of the mobile phone is sufficient.

PUM

| Property | Measurement | Unit |

|---|---|---|

| etching depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com