Transmission and preparation integration assembly for electromechanical automatic gearbox of pure electric vehicle

A pure electric vehicle, automatic transmission technology, applied in electric power units, power units, vehicle components, etc., can solve the problems of increased electrical energy loss, large mechanical power loss, energy waste, etc., to improve stability, increase The effect of output power, improved power and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

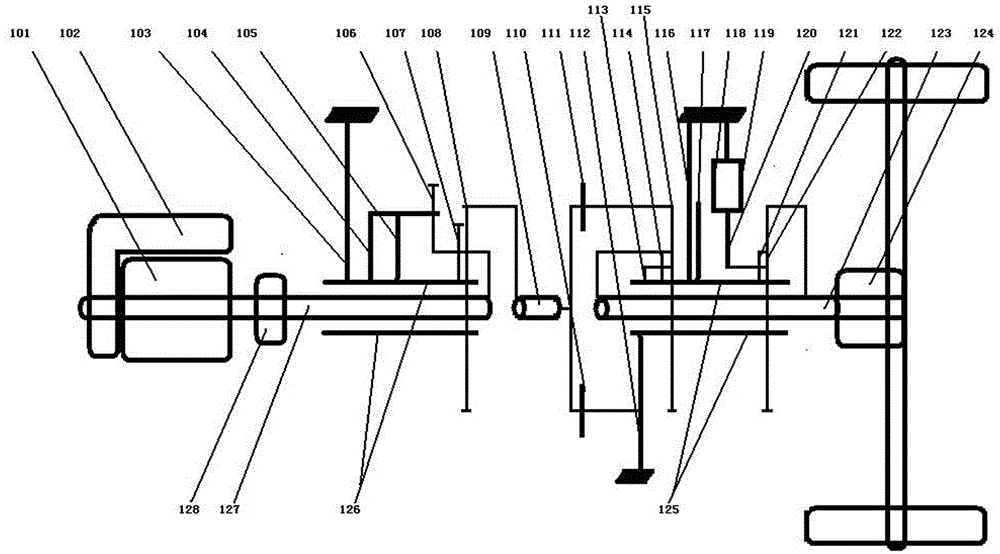

[0017] The fifth-speed (including reverse gear) planetary gear shifting structure of the pure electric vehicle electromechanical automatic transmission transmission maintenance integration assembly of the present invention, and the working principle of the transmission maintenance clutch device of the automatic transmission are as follows: figure 1 shown. The pure electric vehicle electromechanical automatic transmission transmission and maintenance integration assembly includes a permanent magnet super-power drive motor 101, a hydraulic torque converter (transmission torque conversion equipment) 128, an input shaft 127, an intermediate shaft 109, an output shaft 123, a main Gear box 124, etc., permanent magnet super-power drive motor 101 is selected from the utility model patent "Automatically increase and decrease power torque generation and charging multi-functional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com