Heat-exchange cooling box for decks

A cooling box and deck technology, applied in ship propulsion, ship parts, ships, etc., can solve the problem of high deck temperature, achieve the effect of strong heat exchange capacity, stable temperature, and saving transportation resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

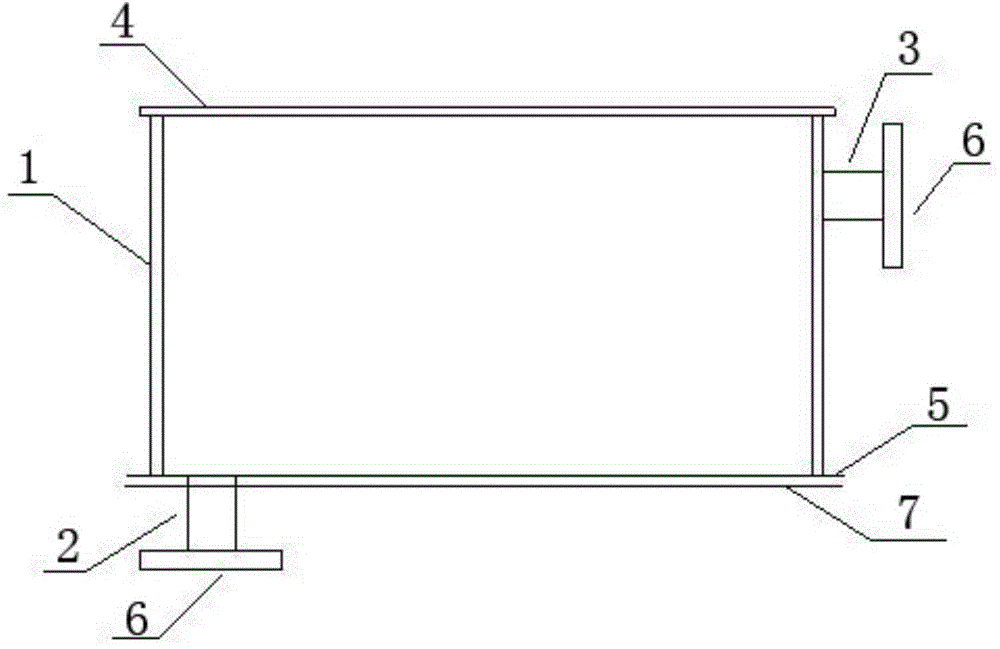

[0017] like figure 1 , is a schematic diagram of the deck heat exchange cooling box of the present invention, including a cooling box body 1, a heat exchange inlet pipe 2 and a heat exchange outlet pipe 3 are installed on the cooling box body 1, and the cooling box body has an upper top surface 4 and a lower bottom surface 5, The cooling box body is a closed cylinder with an upper top surface and a lower bottom surface, and the upper top surface 4 and the lower bottom surface 5 have exhaust pipe passing passages. This exhaust pipe passing passage enables exhaust pipes of different lengths to pass through the cooling box body 1, the heat exchange inlet pipe 2 is installed on the lower bottom surface 5 of the cooling box body, and the heat exchange outlet pipe 3 is installed on the bottom surface of the cooling box body 1 On one side wall and close to upper top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com