Automatic lifting device of ball-cage type constant velocity universal joint holders

A constant velocity universal joint and automatic lifting technology, which is applied in the direction of lifting devices, lifting frames, transportation and packaging, etc., can solve the problems of low efficiency and unsatisfactory automatic lifting, and achieve a high degree of automation and real-time controllable feeding and discharging speeds , the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

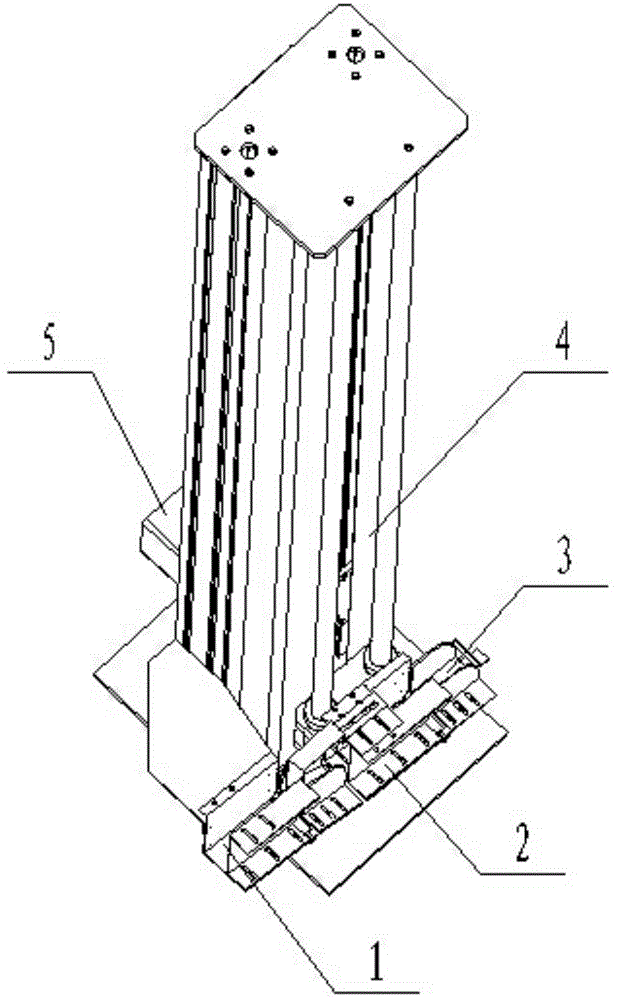

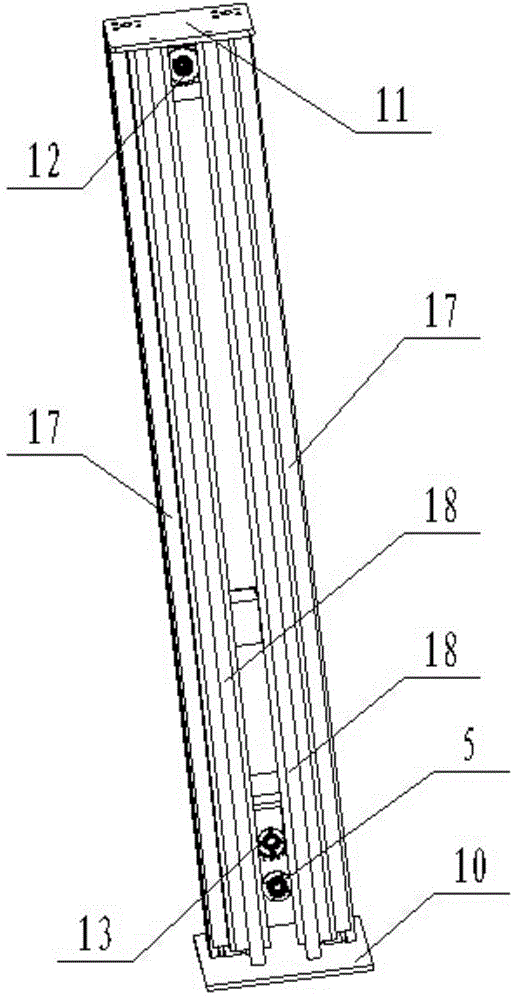

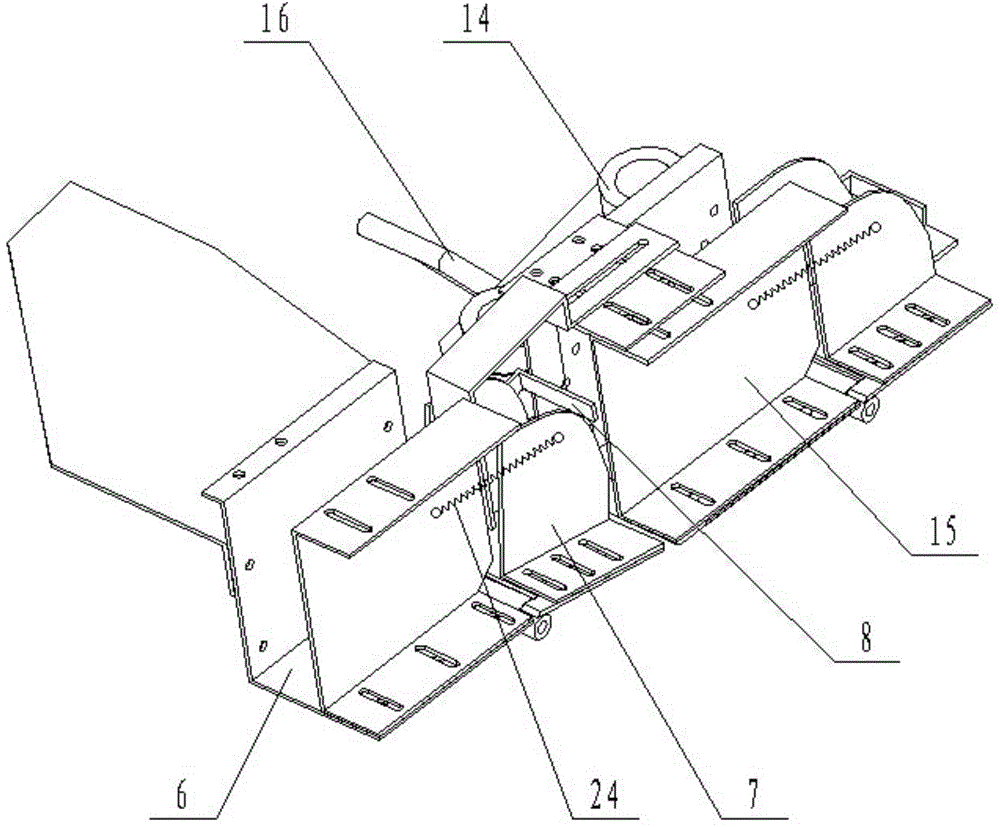

[0031] figure 1 It is a schematic diagram of the overall structure of a cage type constant velocity universal joint cage automatic lifting device of the present invention; figure 2 It is a structural schematic diagram of the lifting mechanism and the drive motor of the present invention; image 3 It is an oblique top view of the three-dimensional structure of the feeding device, lifting platform and unloading device of the present invention; Figure 4 It is an oblique bottom view of the three-dimensional structure of the feeding device, lifting platform and unloading device of the present invention; it can be seen that:

[0032] A ball cage type constant velocity universal joint cage automatic lifting device, including a feeding device 1, a lifting platform 2, an unloading device 3, a lifting track 4 and a driving motor 5;

[0033] The feeding device 1 includes a fixed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap