Continuous bucket type metering system

A metering system and bucket-type technology, applied in the field of machinery, can solve the problems of low operating efficiency and achieve the effects of simple structure, continuous and efficient metering, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

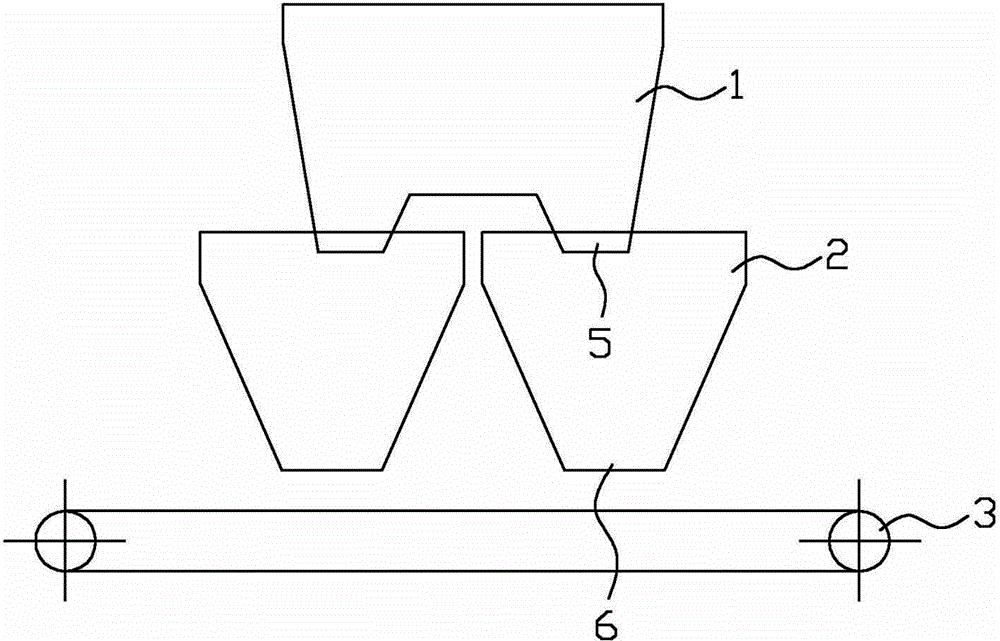

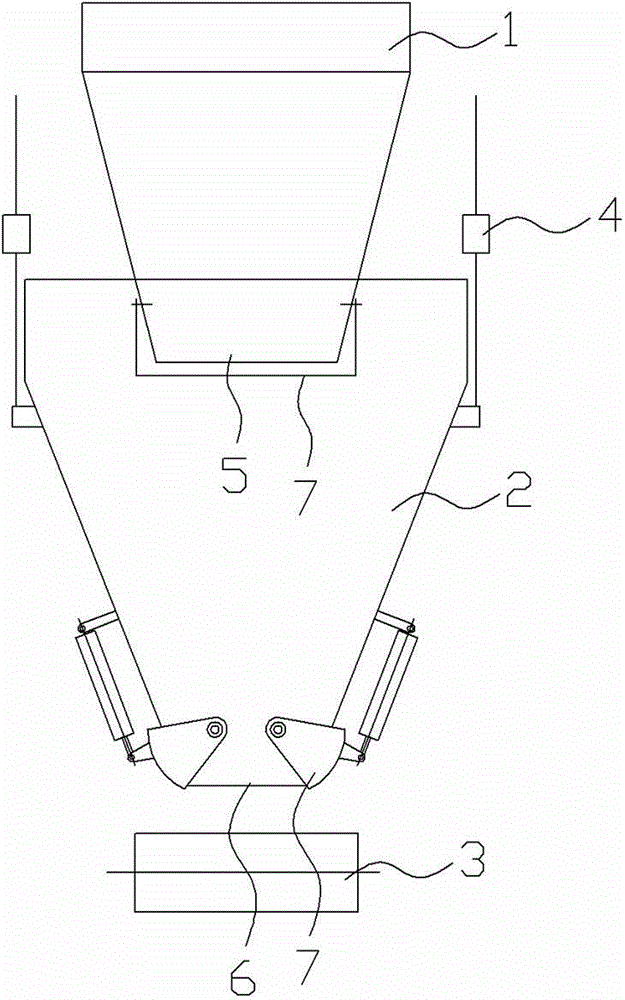

[0008] like figure 1 and 2 As shown, it includes a discharge hopper 1, a weighing hopper 2, a conveyor belt 3 and a control system. The weighing hopper 2 is suspended below the discharge hopper 1 through a mass sensor 4. The bottom of the discharge hopper 1 is provided with two discharge ports 5, There are two weighing hoppers, suspended above the conveyor belt 3 respectively and corresponding to one of the discharge openings 5 of the discharge hopper 1, each discharge opening 5 of the discharge hopper 1 and the discharge of the measurement hopper 2 The opening 6 is provided with a discharge door 7 that can be controlled by the control system.

[0009] The two measuring buckets 2 of the present invention measure alternately, and through the control of the control system, the materials are evenly placed on the conveyor belt 3, so as to realize continuous operation and improve production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com