Catalyst for olefin polymerization and preparation method thereof

A technology of olefin polymerization and catalyst, which is applied in the field of olefin polymerization catalyst and its preparation, which can solve the problem of low catalyst activity and achieve the effects of adjustable catalytic efficiency, improved high temperature resistance, and improved catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

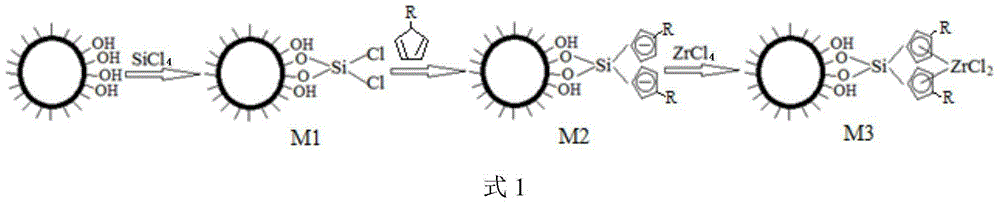

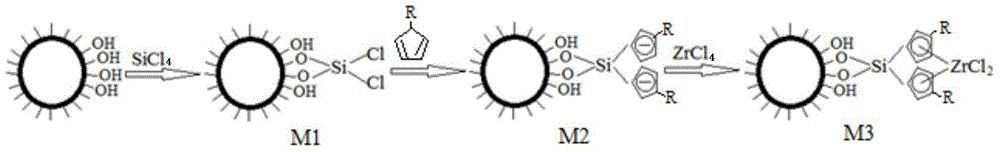

[0033] A. Add 5g of activated silica gel to 60mL of toluene, stir evenly at room temperature, then add 2mL of silicon tetrachloride to it, stir at room temperature for 10min, heat up to 110°C for 24 hours. The solid was filtered and washed 3-5 times with 30-50 mL THF. The product M1 is obtained.

[0034] B. 0.8g Na was added into a Sieran Ke bottle, 10mL tetrahydrofuran was added, and 3mL cyclopentadiene was added, and the mixture was reacted in an ice bath for 24 hours to obtain cyclopentadienyl sodium.

[0035] Under the condition of an ice-water bath, the prepared sodium cyclopentadienyl was added to a 50 mL dry tetrahydrofuran solution of the product M1 to react for 24 hours. The solid was filtered and washed 3-5 times with 30-50 mL THF. The product M2 is obtained.

[0036] C. Under ice-water bath conditions, add 5mL of butyllithium to M2, react for 24 hours, and filter the obtained solids to wash 3-5 times with 30-50mL tetrahydrofuran.

[0037]D. 1g of zirconium tetra...

Embodiment 2

[0040] A. Add 10g of activated silica gel to 120mL of toluene, add 4mL of silicon tetrachloride to it under stirring at room temperature, keep stirring for 10min, then raise the temperature to 110°C for 24 hours. The solid was filtered and washed 3-5 times with 60-80 mL THF. The product M1 is obtained.

[0041] B. Add 0.16g Na, 20mL tetrahydrofuran and 6mL cyclopentadiene into a sieran, and react the mixture in an ice bath for 24 hours to obtain cyclopentadienyl sodium.

[0042] Under the condition of ice-water bath, cyclopentadienyl sodium was added to M1, and after reacting for 24 hours, it was washed with 60-80 mL tetrahydrofuran for 3-5 times. The product M2 is obtained.

[0043] C. In an ice-water bath, add 10 mL of butyllithium to M2, discard the liquid after 24 hours of reaction, and wash the solid with 60-80 mL of tetrahydrofuran for 3-5 times.

[0044] D. Add 2g of zirconium tetrachloride and dissolve it in 40mL of tetrahydrofuran, and ultrasonicate for 1 hour at r...

Embodiment 3

[0047] A. Add 20g of activated silica gel to 240mL of toluene, add 8mL of silicon tetrachloride to it under stirring at room temperature, and continue to stir for 10min, then react at 110°C for 24 hours, and wash the solid with 60-80mL of tetrahydrofuran for 3- 5 times. The product M1 is obtained.

[0048] B. Add 5.6g of potassium, 40mL of tetrahydrofuran and 12mL of cyclopentadiene into a Sieranke bottle, and react the mixture in an ice bath for 24 hours to obtain cyclopentadienyl sodium.

[0049] Under the condition of ice-water bath, potassium cyclopentadienyl was added to M1 to react for 24 hours, and the solid matter was washed 3-5 times with 60-80 mL tetrahydrofuran. The product M2 is obtained.

[0050] C. In an ice-water bath, add 20 mL of butyllithium to M2 and react for 24 hours. After filtering, the solid is washed with 60-80 mL of tetrahydrofuran for 3-5 times.

[0051] D. Add 4g of zirconium tetrachloride and dissolve it in 80mL of tetrahydrofuran, and ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com