A kind of anti-breaking acrylate pressure-sensitive adhesive for wall and preparation method thereof

A technology of acrylate and polytetrahydrofuryl acrylate, which is applied in the direction of adhesives, ester copolymer adhesives, graft polymer adhesives, etc., and can solve the constraints on the development and application of pressure-sensitive adhesives for walls and low bonding strength , material waste and other issues, to achieve good weather resistance and processability, high bonding performance, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

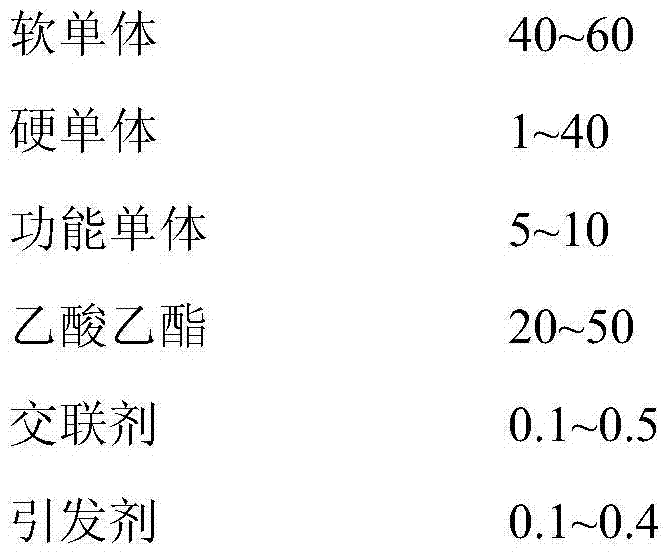

[0038] A method for preparing a break-resistant acrylate pressure-sensitive adhesive for walls, which is made of the following raw materials in parts by weight:

[0039]

[0040] Wherein the mass ratio of polytetrahydrofuryl acrylate and pyridine-2-acrylic acid is 6:3;

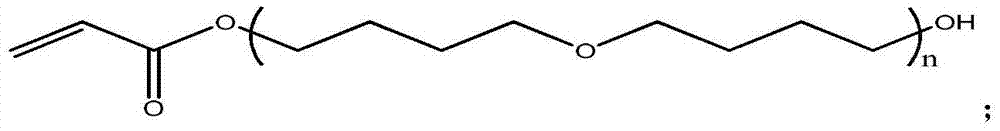

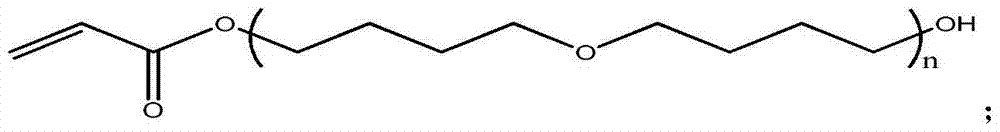

[0041] Preparation of polytetrahydrofuryl acrylate;

[0042] Dissolve polytetrahydrofuran ether diol with a number average molecular weight of 600 in methylene chloride, and the concentration of polytetrahydrofuran ether diol dissolved in methylene chloride is 20 wt%, and then dropwise added to acrylic acid chloride for reaction, polytetrahydrofuran ether diol The molar ratio to acrylic acid chloride is 1:1, the reaction temperature is 10°C, and the reaction time is 2h. During the reaction, triethylamine is used to absorb the hydrogen chloride gas generated during the reaction. The molar ratio of triethylamine to acrylic acid chloride is 1: 1; The reaction product is separated by extraction, vacuum distill...

Embodiment 2

[0048] A method for preparing a break-resistant acrylate pressure-sensitive adhesive for walls, which is made of the following raw materials in parts by weight:

[0049]

[0050] Wherein the mass ratio of polytetrahydrofuryl acrylate and pyridine-2-acrylic acid is 7:3;

[0051] Preparation of polytetrahydrofuryl acrylate;

[0052] Dissolve polytetrahydrofuran ether diol with a number average molecular weight of 2000 in methylene chloride, and the concentration of polytetrahydrofuran ether diol dissolved in dichloromethane is 30wt%, and then dropwise added to acrylic acid chloride for reaction, polytetrahydrofuran ether diol The molar ratio to acrylic acid chloride is 1.3:1, the reaction temperature is 30°C, and the reaction time is 3h. During the reaction, triethylamine is used to absorb the hydrogen chloride gas generated during the reaction. The molar ratio of triethylamine to acrylic acid chloride is 1: 1; The reaction product is separated by extraction, vacuum distilla...

Embodiment 3

[0058] A method for preparing a break-resistant acrylate pressure-sensitive adhesive for walls, which is made of the following raw materials in parts by weight:

[0059]

[0060] Wherein the mass ratio of polytetrahydrofuryl acrylate and pyridine-2-acrylic acid is 6:3;

[0061] Preparation of polytetrahydrofuryl acrylate;

[0062] The polytetrahydrofuran ether diol that the number average molecular weight is 1000 is dissolved in methylene chloride, and the concentration that polytetrahydrofuran ether diol is dissolved in methylene chloride is 22wt%, is added dropwise in the reaction in the acrylic acid chloride, polytetrahydrofuran ether diol The molar ratio to acrylic acid chloride is 1.1:1, the reaction temperature is 15°C, and the reaction time is 2.5 hours. During the reaction, triethylamine is used to absorb the hydrogen chloride gas generated during the reaction. The molar ratio of triethylamine to acrylic acid chloride is 1 : 1; the reaction product generates polyte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap