Drilling boom device of two-boom hydraulic rock bolt drilling carriage

A technology of rock bolter and drilling arm, which is applied in the field of coal mine excavation equipment and drilling arm device, which can solve the problems of inability to construct forward, complex structure, and inability to adapt, so as to improve the degree of mechanization, ensure personal safety, and have reliable strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

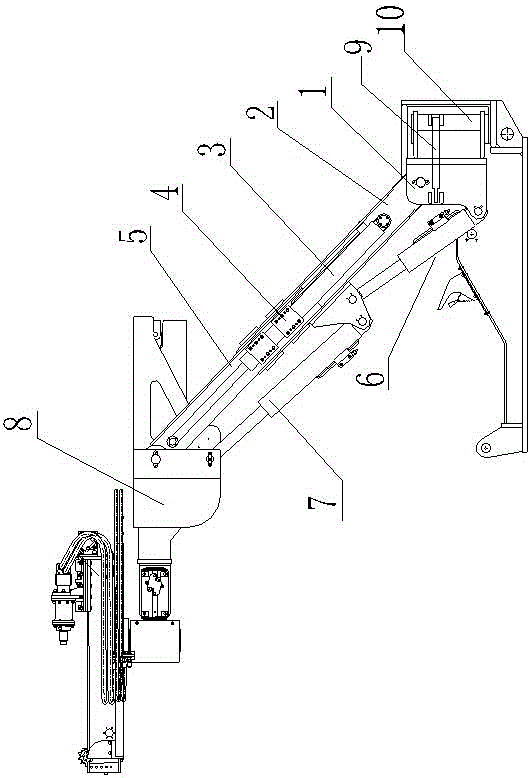

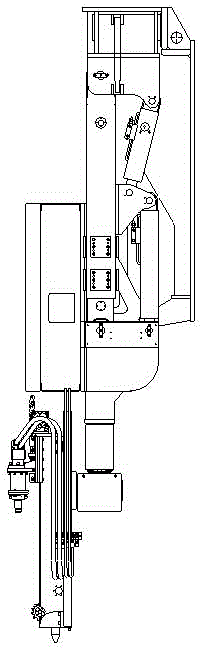

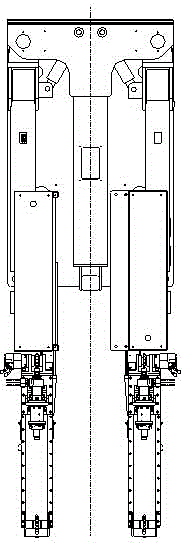

[0018] see figure 1 — image 3 , a drill arm device of a two-arm hydraulic rock bolt drilling rig, the drill arm device comprises a drill arm hinge seat 1, an outer cylinder of a telescopic arm 2, a telescopic oil cylinder 3, a clearance adjustment block 4, a telescopic arm 5, and a drill arm support oil cylinder 6. Adjusting oil cylinder 7, propulsion mechanism 8, drill arm swinging oil cylinder 9, drill arm fixing support 10, the telescopic oil cylinder 3 is arranged between the telescopic arm 5 and the telescopic arm outer cylinder 2, and the telescopic arm outer cylinder 2 passes through. The pin shaft is pivotally connected with the drill arm hinge seat 1, and the drill arm hinge seat 1 is fixed on the drill arm fixed support 10 through the pin shaft; the drill arm support oil cylinder 6 is respectively connected with the drill arm hinge seat 1 through the pin shaft. Connected to the outer cylinder 2 of the telescopic arm, the adjusting oil cylinder 7 is respectively con...

Embodiment 2

[0020] see figure 1 — image 3 , as an improvement of the present invention, the telescopic arm 5 and the adjusting oil cylinder 7 are parallel, which facilitates the control of the propulsion mechanism 8 .

Embodiment 3

[0022] see figure 1 — image 3 , as an improvement of the present invention, the drill arm also includes a clearance adjustment block 4, the number of the clearance adjustment block is 4, and the upper, lower, left and right sides of the front end of the outer cylinder 2 of the telescopic arm are provided with Gap adjustment block, the function of the gap adjustment block is to adjust the gap between the outer cylinder of the telescopic arm and the telescopic arm.

[0023] How it works: as figure 1 As shown in the figure, when the hydraulic rock bolt drilling rig operates at a high position, the drilling arm support cylinder 6 feeds oil and pushes the outer cylinder 2 of the telescopic arm to raise; the telescopic arm 5 is extended through the telescopic oil cylinder 3 and the adjustment oil cylinder 7, Push the propulsion mechanism 8 up to the working height, adjust the oil return of the oil cylinder 7 and pull the propulsion mechanism 8 to rotate around the upper pin of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com