Special control system for producing oil-gas well plunger gas lift

A technology for control systems and oil and gas wells, applied in the direction of wellbore/well valve devices, wellbore/well components, production fluids, etc., which can solve the problem of single function of the controller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

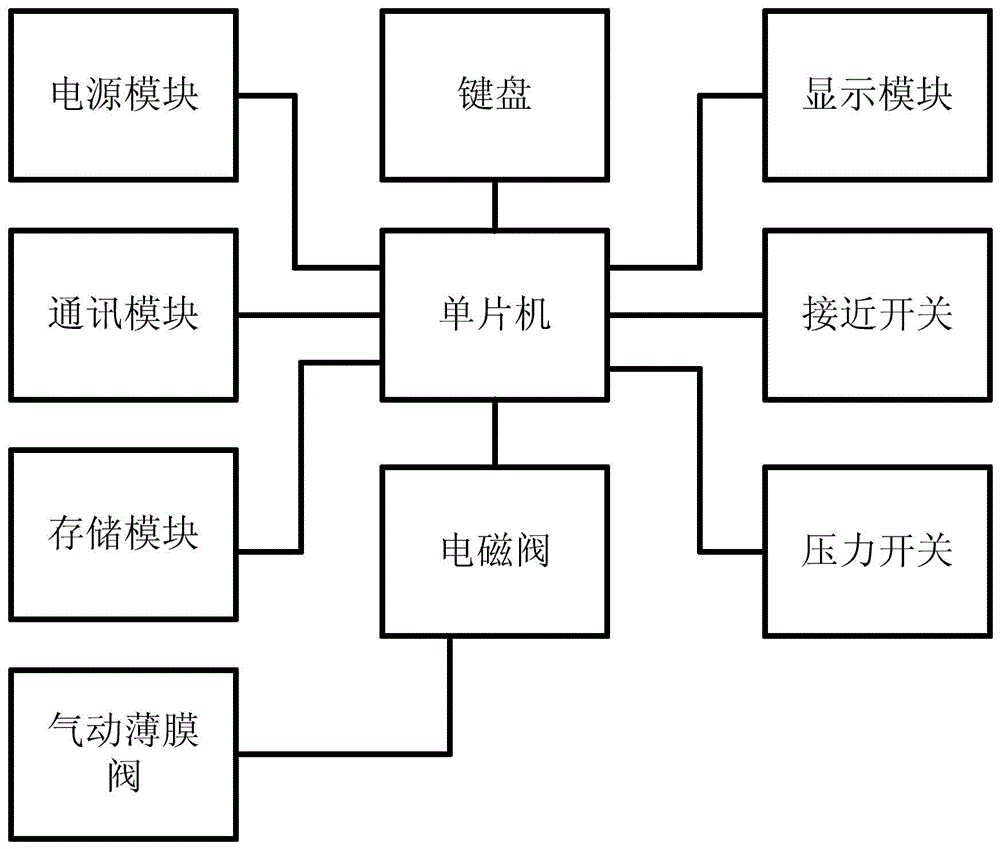

[0026] Embodiment 1: as figure 1 As shown, a special control system for plunger gas lift production in oil and gas wells, the power supply module, communication module, and storage module are connected to the single-chip microcomputer, the single-chip computer is connected to the keyboard, solenoid valve, display module, proximity switch and pressure switch, and the solenoid valve is connected to the pneumatic Membrane valve.

Embodiment 2

[0027] Embodiment 2: as figure 1 As shown, a special control system for plunger gas lift production of oil and gas wells, the plunger arrival signal output end of the proximity switch is connected with the plunger arrival signal input end of the single-chip microcomputer.

[0028] The pressure signal output end of the pressure switch is connected with the pressure signal input end of the single chip microcomputer.

[0029] The solenoid valve drive signal output end of the single chip microcomputer is connected with the solenoid valve drive signal input end.

[0030] The driving input port of the pneumatic membrane valve is connected with the driving output port of the pneumatic membrane valve of the electromagnetic valve.

[0031] The power supply module, the communication module, the memory module, the keyboard and the display module are respectively connected with the corresponding ports of the single chip microcomputer.

[0032] The well shut-in time and well open time ar...

Embodiment 3

[0036] Embodiment 3: as figure 1 As shown, a special control system for plunger gas lift production in oil and gas wells is mainly composed of power supply module, communication module, storage module, keyboard, display module, single chip microcomputer, proximity switch, pressure switch, solenoid valve, pneumatic membrane valve . The power supply module provides energy for the device; the communication module is used for indoor monitoring and communication with the upper computer; the storage module is used for storing setting parameters and field data; the keyboard is used for inputting instructions to the device; the display module is used for displaying information; It is used to receive the signal from the plunger to the wellhead; the pressure switch is used to receive the casing pressure and oil pressure signals of the wellhead; the single-chip microcomputer is used to communicate and control with each module; the solenoid valve receives the control signal of the single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com