Engine valve driving mechanism and engine valve driving device

A technology of engine valves and driving mechanisms, which is applied in the direction of valve driving devices, engine components, machines/engines, etc., can solve the problems of inability to achieve optimal engine performance, large carbon dioxide emissions, and reduced service life. Effects on fuel consumption and service life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0039] The engine valve drive mechanism and valve drive device provided by the invention have continuously variable lift.

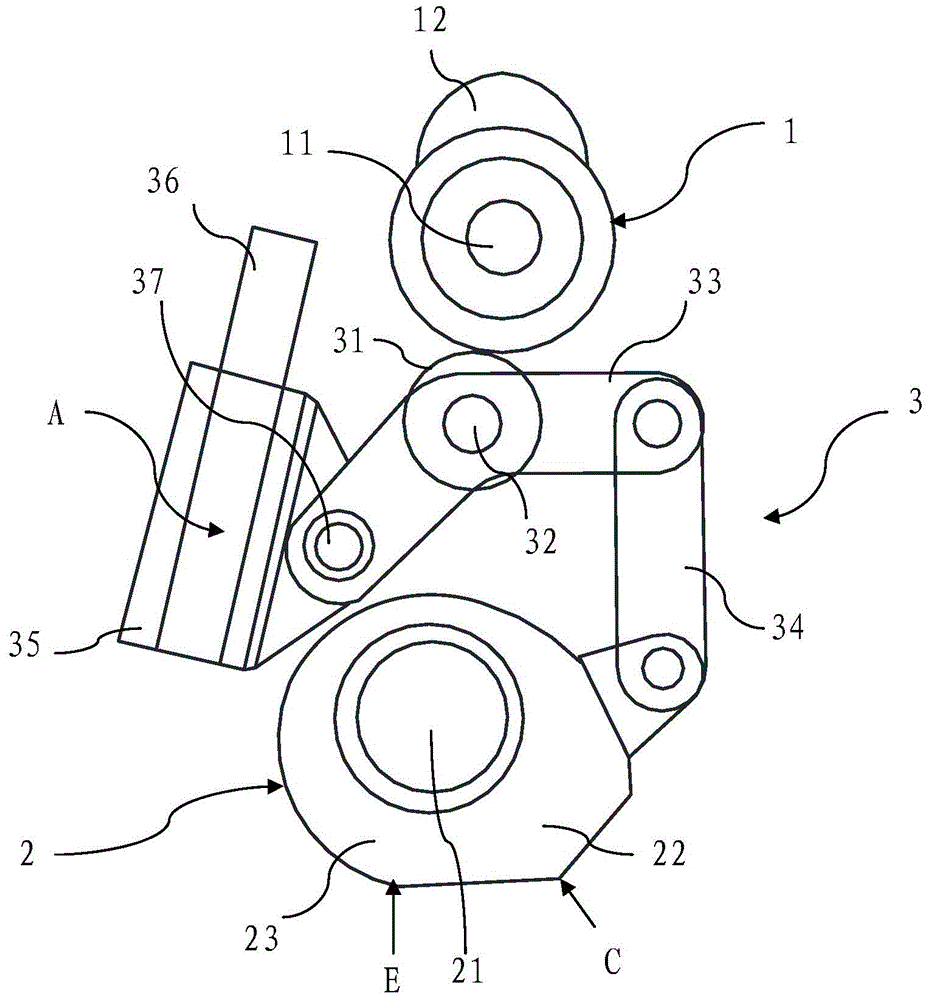

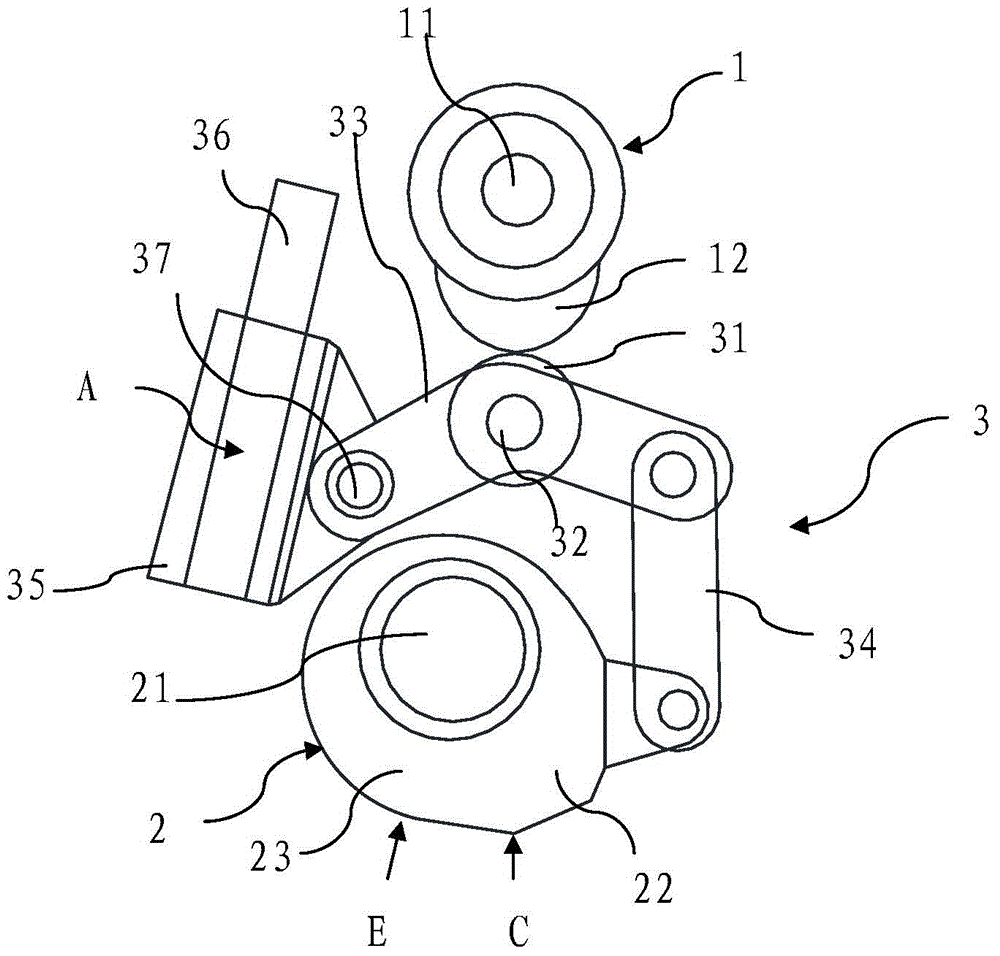

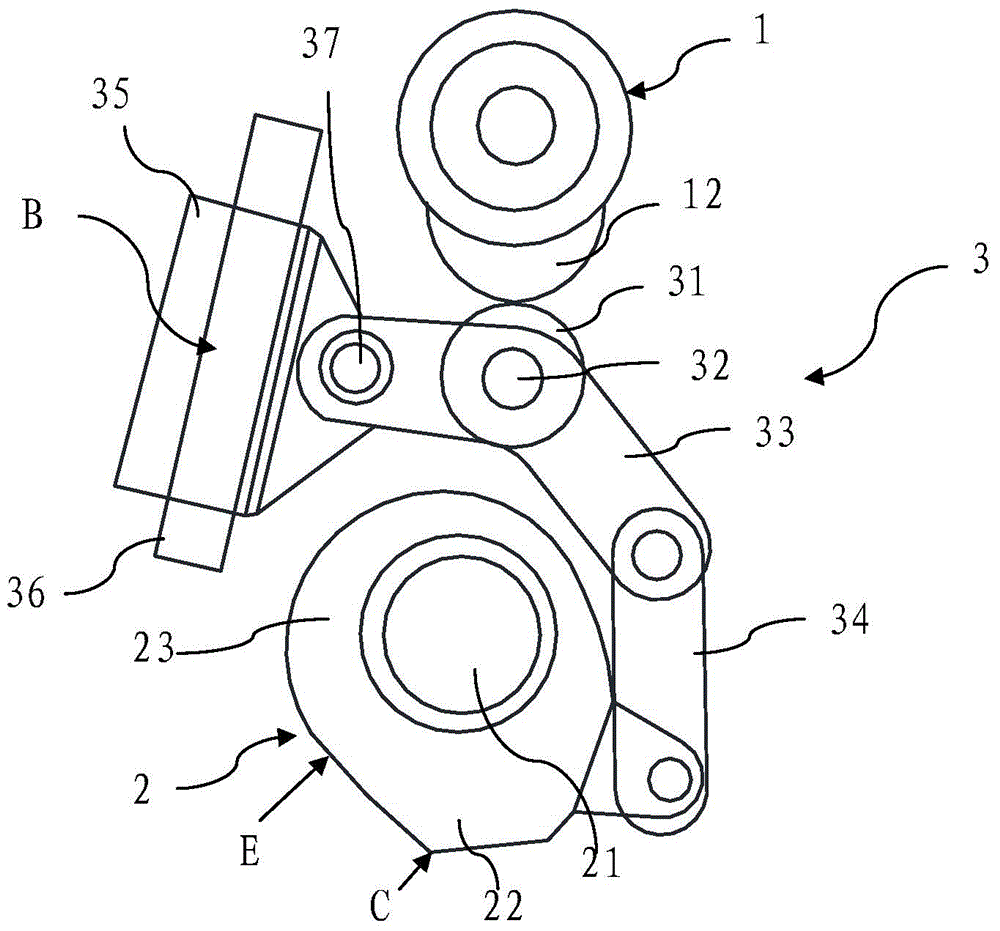

[0040] Such as Figure 1-3 As shown, the engine valve drive mechanism provided by the present invention includes a main camshaft 11, a main cam 1 mounted on the main camshaft 11, a control shaft 21 arranged in parallel with the main camshaft 11, and a control shaft 21 rotatably installed on the control shaft. On 21, it is used to drive the auxiliary cam 2 of engine valve opening and closing.

[0041] A connecting driving member 3 for driving the auxiliary cam 2 to rotate is connected between the main cam 1 and the auxiliary cam 2 .

[0042] The connecting drive member 3 includes a curved arm 33 , a connecting rod 34 , a trunnion 35 , a guide rod 36 and a roller 31 .

[0043] The above-mentioned roller 31 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap