Stress-free pipe gallery system

A stress-free, pipe gallery technology, applied in the direction of pipe components, pipe supports, pipes/pipe joints/fittings, etc., can solve the problems of small compensation distance, high operating cost, long construction period, etc. The effect of large span of pipe gallery and convenient arrangement of branch pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

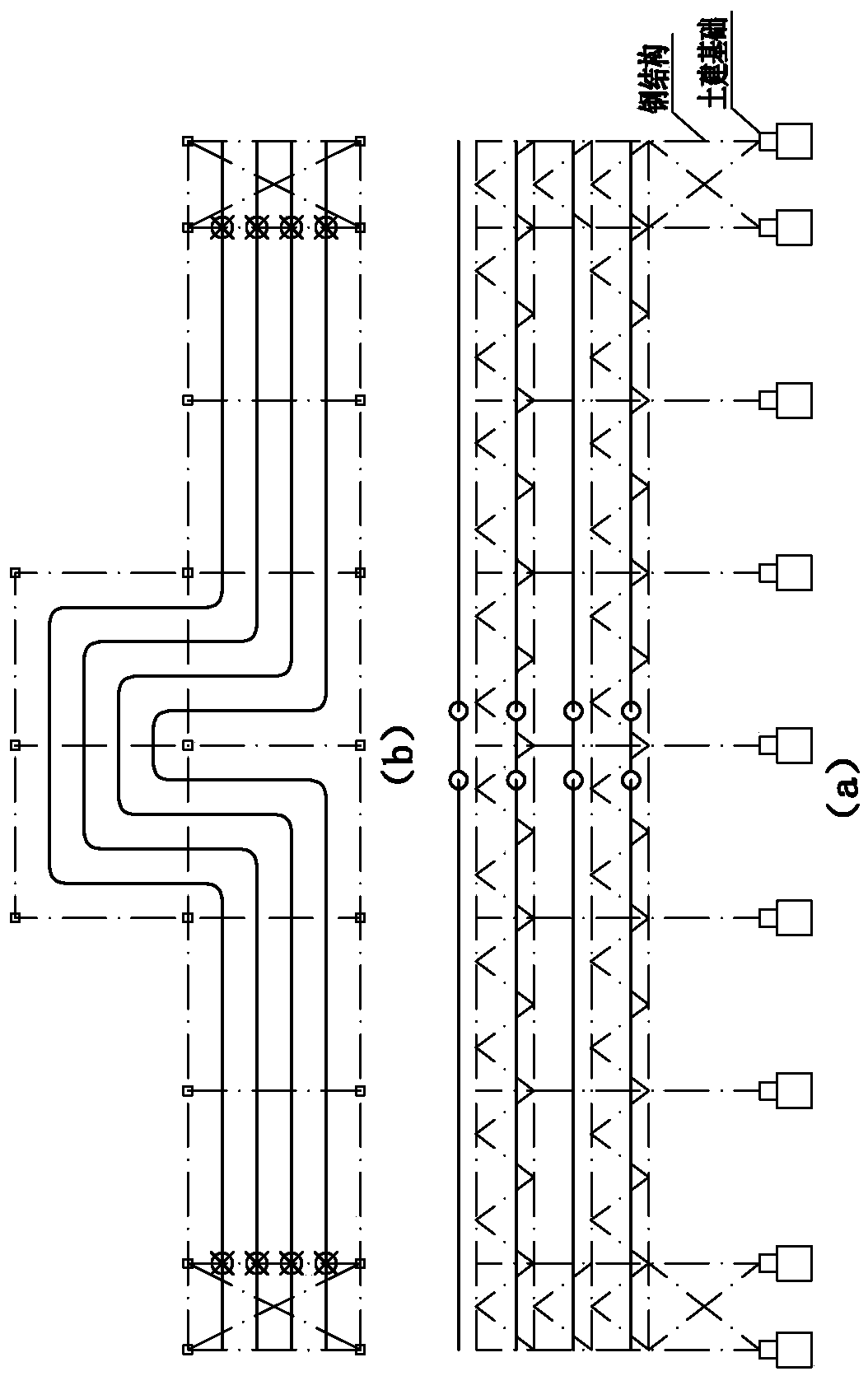

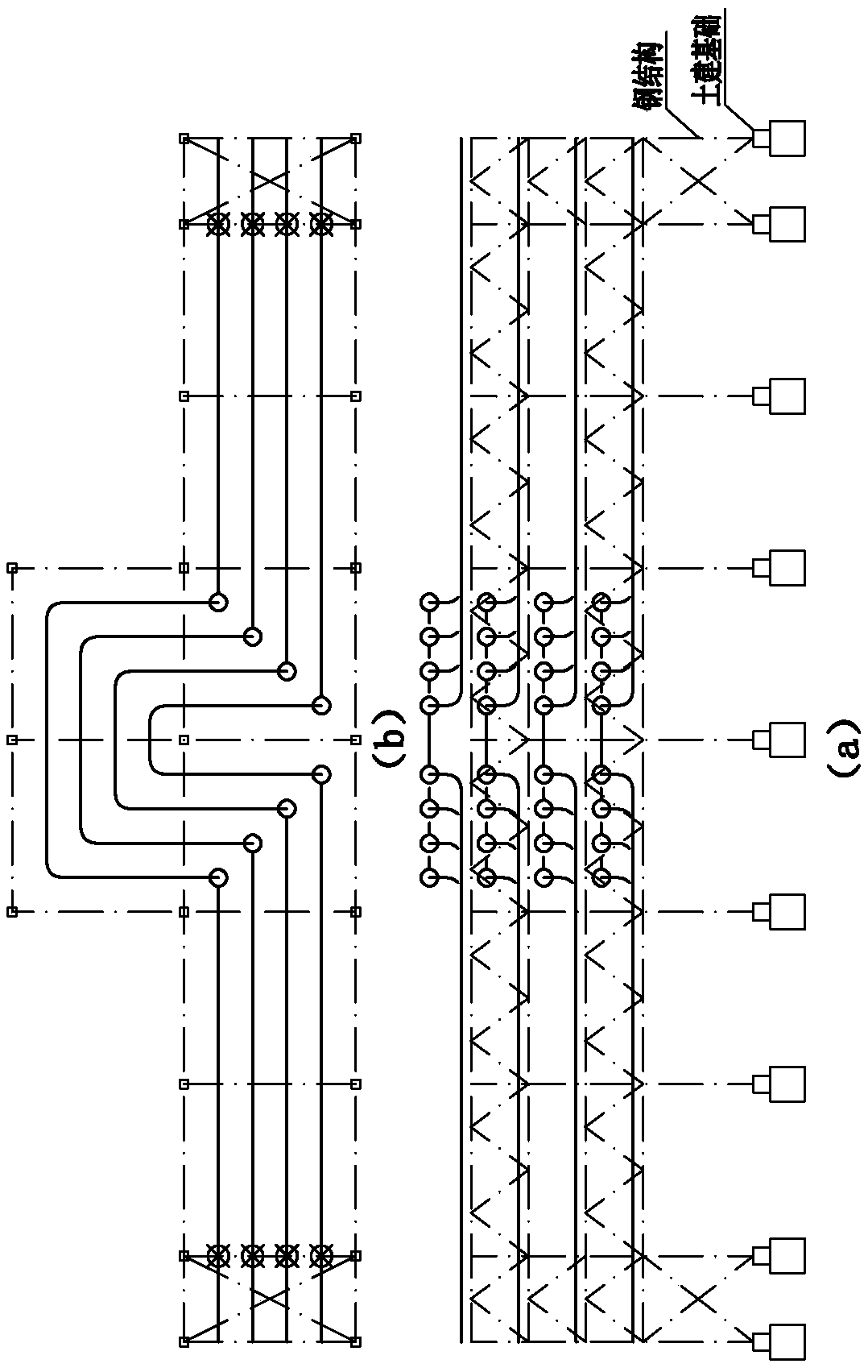

[0043] Such as Figure 7 , 9 shown.

[0044] A stress-free pipe gallery system, which is composed of several pipes 1 installed on the support 2, and each pipe 1 installed on the support 2 is evenly spaced with a length compensation mechanism 3 for preventing its thermal expansion and contraction from being damaged. The length between adjacent length compensating mechanisms 3 can be more than 60 meters, wherein more than 200 meters is the most economical, and the longest can reach 500 meters. Each length compensation mechanism 3 is composed of four rotary compensators 5 and connecting pipe fittings 6. The connecting pipe fittings 6 are composed of elbows 601 and connecting pipes 602. In order to save floor space, each length compensation mechanism is arranged in a misplaced position, occupying only a height The space reduces the horizontal footprint, making the extension meter very small, only one-third to one-tenth of the extension meter of the traditional pipe gallery. Fi...

Embodiment 2

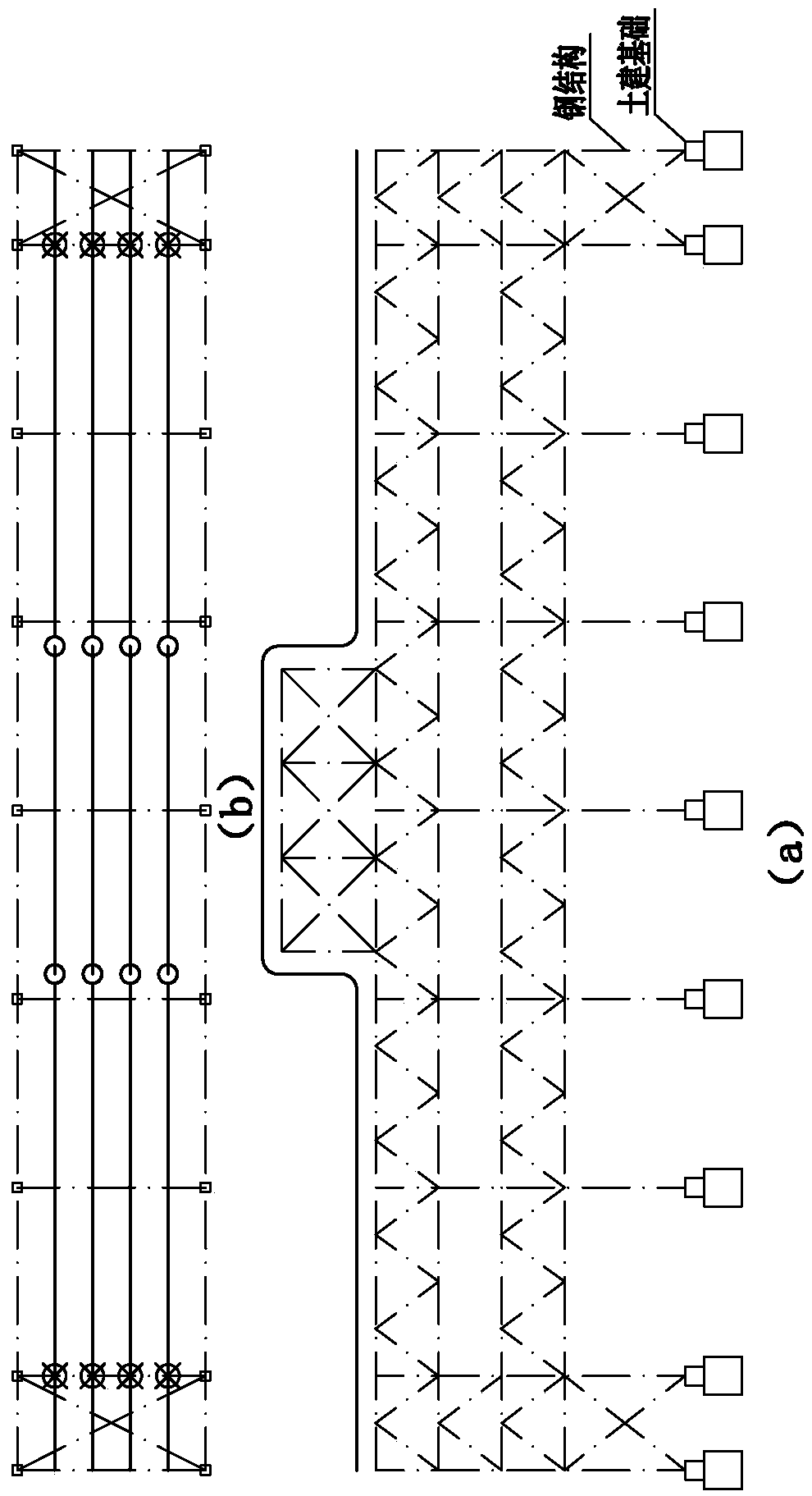

[0050] Such as Figure 8 shown.

[0051] The difference between this embodiment and Embodiment 1 is that the support 2 for the movable supporting pipeline is canceled, and the suspension frame with a suspension cable is used instead of the support. The pipeline is laid flat on the frame structure, and the frame structure can be a single-layer or multi-layer structure. The suspension tower can be built between two length compensation mechanisms 3. This situation is suitable for lighter pipelines and larger length compensation mechanisms (such as 400 meters, 500 meters, etc.), when adjacent length compensation mechanisms 3 When the distance is small, the suspension tower and the fixed bracket of the length compensation mechanism can also be directly combined into one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com