Burner and igniter thereof

A technology of igniter and burner, which is applied in the direction of combustion ignition, burner, gas fuel burner, etc. It can solve the problem that the igniter cannot mix gas and air sufficiently, and achieve the goal of reducing emission rate, mixing fully, and improving combustion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

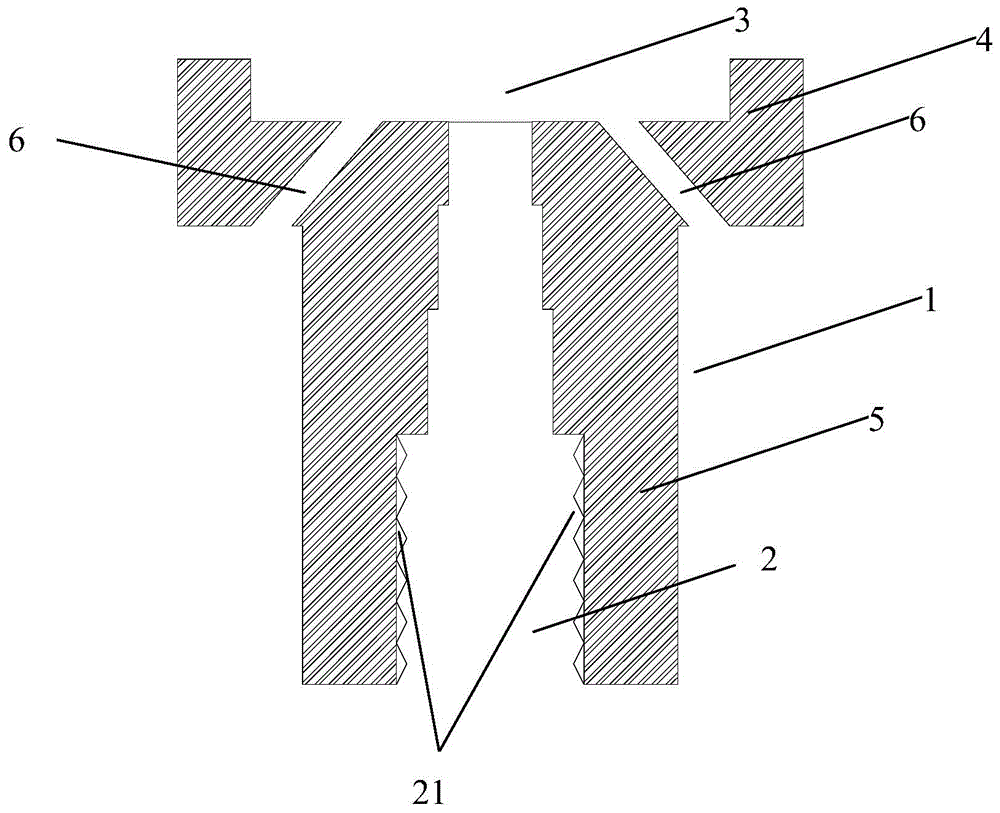

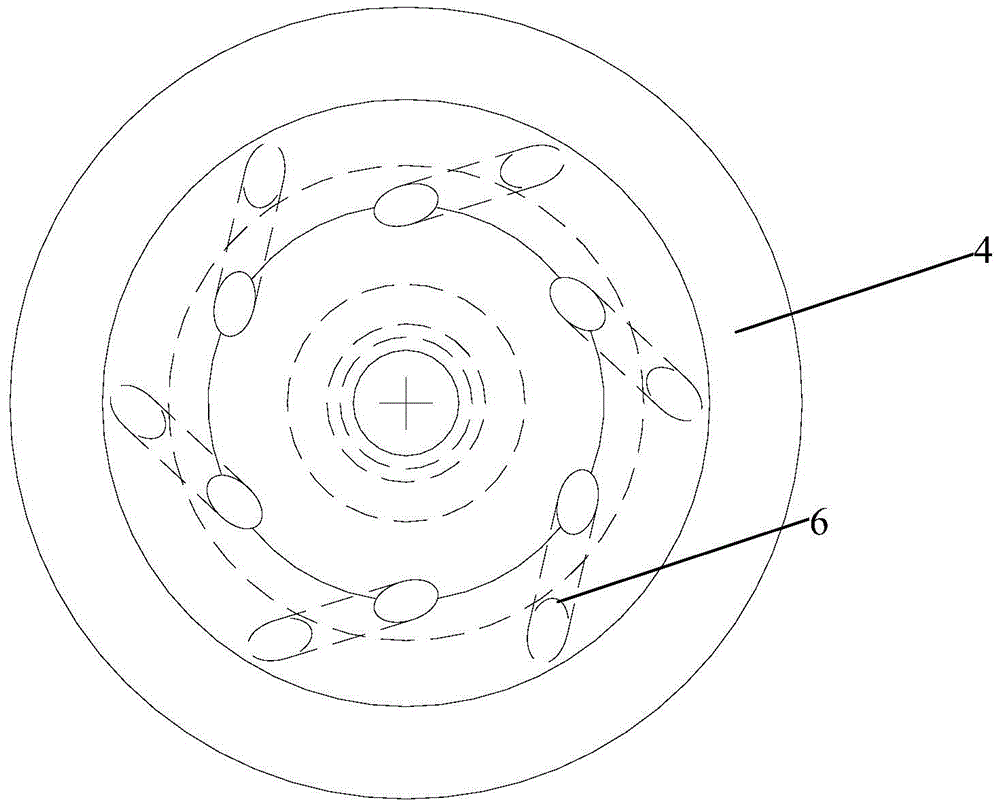

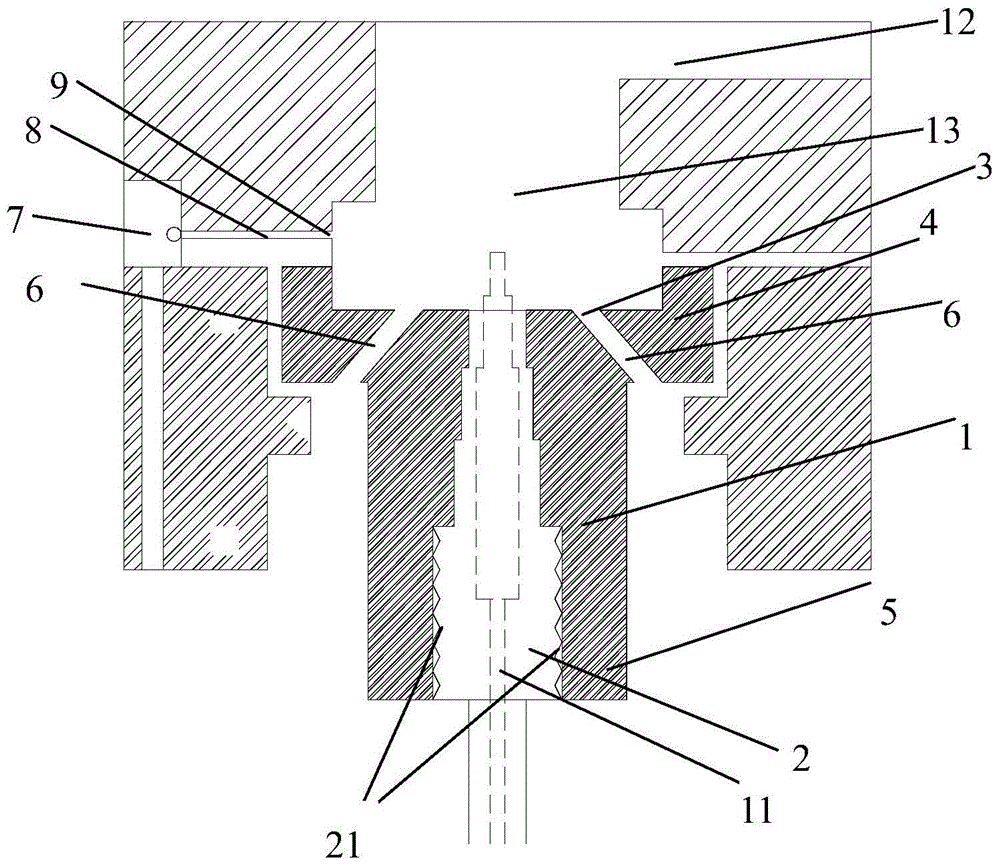

[0019] Such as figure 1 As shown, the igniter of the present invention includes a pressurized air introduction device 1 and an ignition channel 2 passing through the pressurized air introduction device 1 . An ignition device and / or a safety device may be arranged in the ignition channel 2 . The compressed air introduction device 1 comprises a cylindrical upper part 4 and a cylindrical lower part 5 , the diameter of the cylindrical upper part 4 is larger than the diameter of the cylindrical lower part 5 . A concave table area 3 is provided on the top of the upper part 4 of the cylinder. The depth of the concave table area 3 is about 1 / 2 of the thickness of the upper part 4 of the cylinder. The bottom end of the cylindrical upper part 4 is provided with a plurality of air passages 6 surrounding the center of the compressed air introduction device 1 . The axes of the plurality of air passages 6 are all inclined towards the same direction to introduce compressed air to the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com