Aberration-free absolute inspection method of ellipsoidal surface

An inspection method and ellipsoid technology, applied in the field of optical inspection, can solve the problems of high production cost and affect the test accuracy, and achieve the effect of high accuracy and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

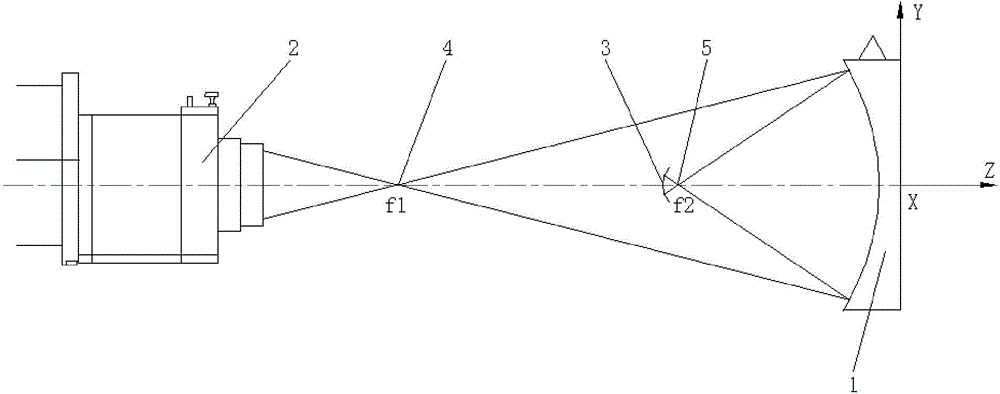

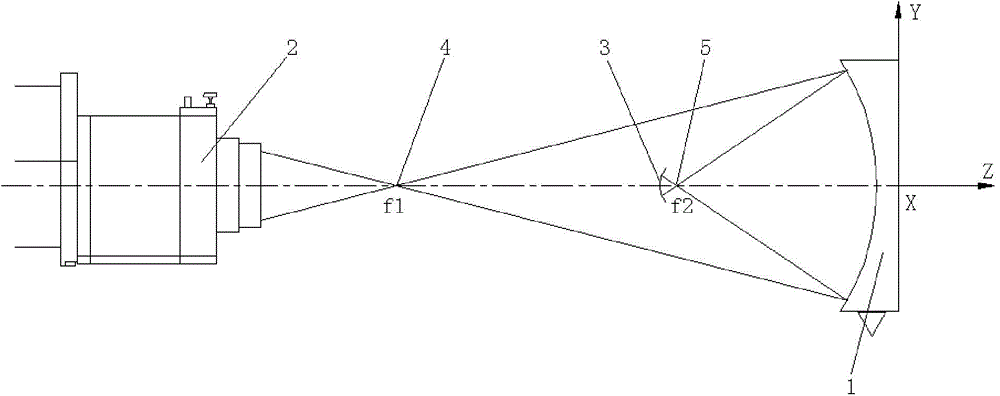

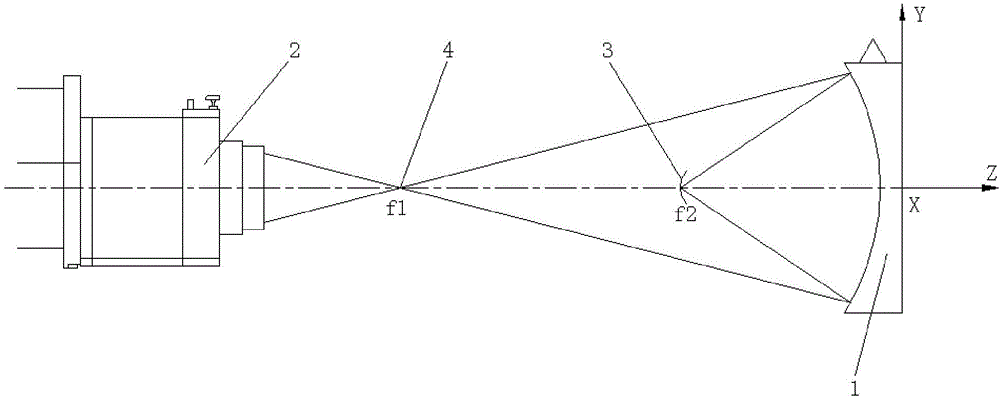

[0032] Figure 1 to Figure 5 An embodiment of the aberration-free absolute inspection method of an ellipsoidal surface of the present invention is shown, the method includes the following steps:

[0033] S1: Measurement: Use the spherical wave interferometer 2 and the spherical mirror 3 to perform aberration-free zero position inspection and cat's eye position inspection on the ellipsoid 1, and perform the following sub-steps specifically:

[0034] S11: The spherical wave interferometer 2 sends a spherical test wave to the ellipsoid 1, and the spherical center 4 of the spherical test wave coincides with the far focus f1 of the ellipsoid 1, and the spherical mirror 3 is placed between the spherical wave interferometer 2 and the ellipsoid 1 and the spherical mirror 3 faces the ellipsoidal surface 1, the center of curvature 5 of the spherical mirror 3 coincides with the near focal point f2 of the ellipsoidal surface 1, and the aberration-free zero position test is carried out and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com