Three-dimensional rotating angle measurement method and device adopted by same

A corner measurement and three-dimensional technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of difficult to improve measurement accuracy, and achieve the effect of convenient installation and operation, mature and reliable technology, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

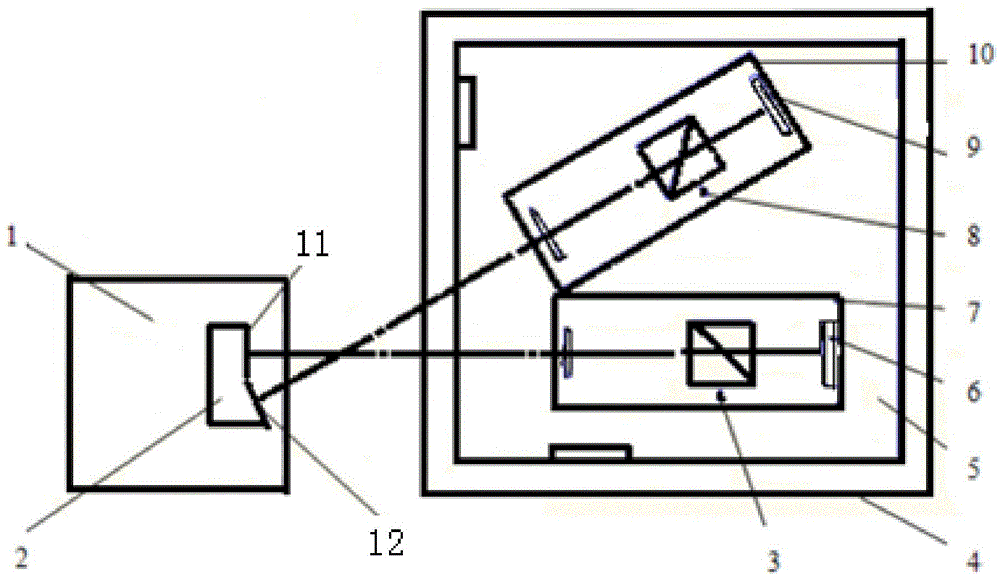

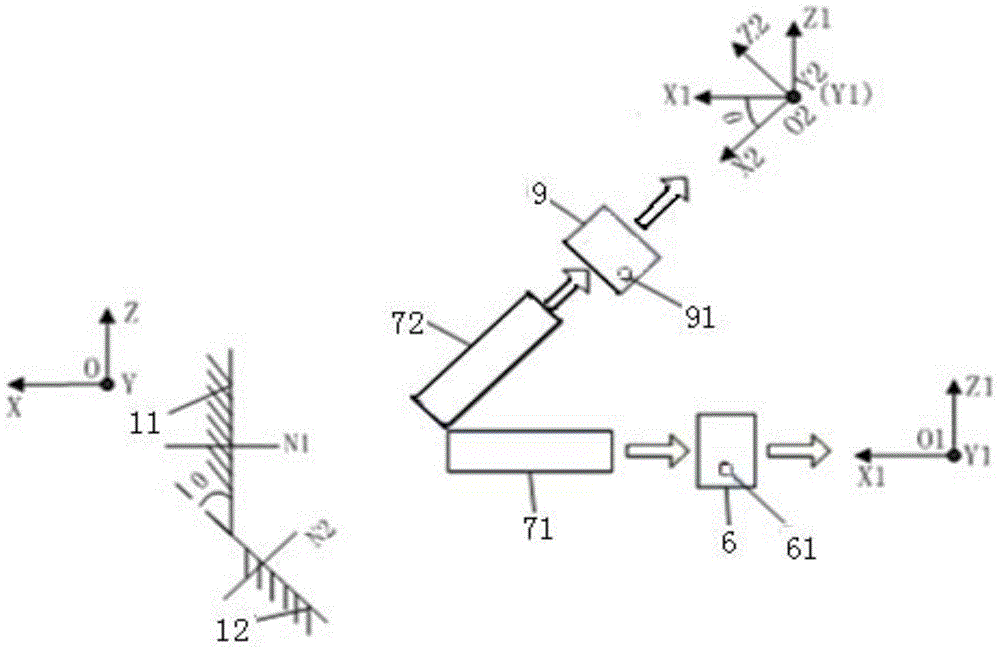

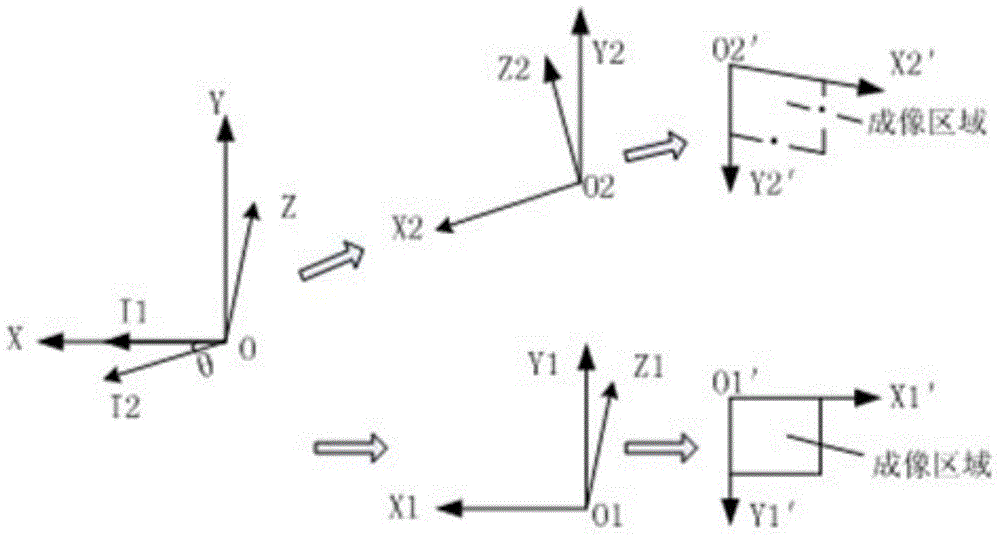

[0032] The present invention performs measurement based on the detection principle of the autocollimator. The three-dimensional rotation angle measuring device includes a measuring device body composed of two two-dimensional autocollimators and a reflective component 2 (ie, a cooperative target). During the measurement, the first autocollimator 7 in the measuring device is aimed at the specular reflection surface 11 of the reflecting part, and the two-dimensional angle change of the specular reflection surface of the reflecting part is measured by the optical self-collimation measurement principle; in the same way, the second autocollimation The straight meter 10 measures the two-dimensional angle change of the inclined reflecting surface 12 of the reflecting part. After the data processing center of the three-dimensional measuring device receives the angle information, the angle value of the three-dimensional turning angle can be calculated according to the formula, and the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com