Magnetic focusing coils and setting method of array of magnetic focusing coils

A coil array, magnetic focusing technology, applied in the field of magnetic focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

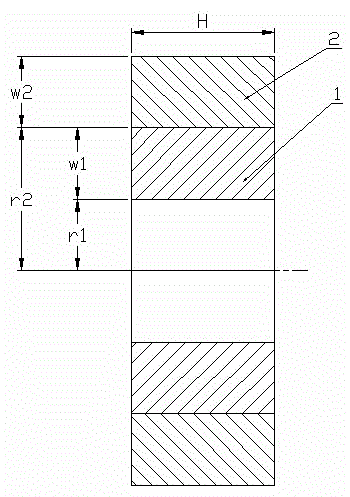

[0034] as attached figure 1 As shown, it is a transmitting array, the inner radius r1 of the coil 1 is 10cm, the outer radius is 20cm, the transverse thickness W of the winding wire is 1cm, and the longitudinal height H is 2cm; the inner radius r2 of the coil 2 is 20cm, and the outer radius is 30cm, The transverse thickness W of the winding wire is 1 cm, and the longitudinal height H is 2 cm;

[0035] Both are wound with enameled wire with a wire diameter of 0.51mm. The inner circle is wound with 769 turns and the outer circle is wound with 504 turns.

Embodiment 2

[0037] as attached figure 1 As shown, it is a transmitting array, the inner radius r1 of the coil 1 is 10cm, the outer radius is 20cm, the transverse thickness W of the winding wire is 1cm, and the longitudinal height H is 2cm; the inner radius r2 of the coil 2 is 20cm, and the outer radius is 30cm, The transverse thickness W of the winding wire is 1 cm, and the longitudinal height H is 2 cm;

[0038] Both are wound with enameled wire with a wire diameter of 0.51mm. The inner circle is wound with 769 turns and the outer circle is wound with 504 turns. The total length L of the coil wires is 918m.

[0039] Outside the coil 2, a receiving coil 3 is nested. The inner radius of the receiving coil 3 is 30cm, and the outer radius is 40cm. The horizontal thickness W of the winding wire is 1cm, and the vertical height H is 2cm.

[0040] To sum up: if the size of the coil is reduced proportionally and the magnetic field distribution remains unchanged, the design can be miniaturized. It...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Inner radius | aaaaa | aaaaa |

| Outer radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com