A high-concentration n-type doped thin germanium material on an insulating layer and its manufacturing method

An insulating layer, manufacturing method technology, applied in the field of materials, can solve the problems of rough material surface, immature technology, expensive equipment, etc., and achieve the effects of high crystal quality, increased activation rate, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

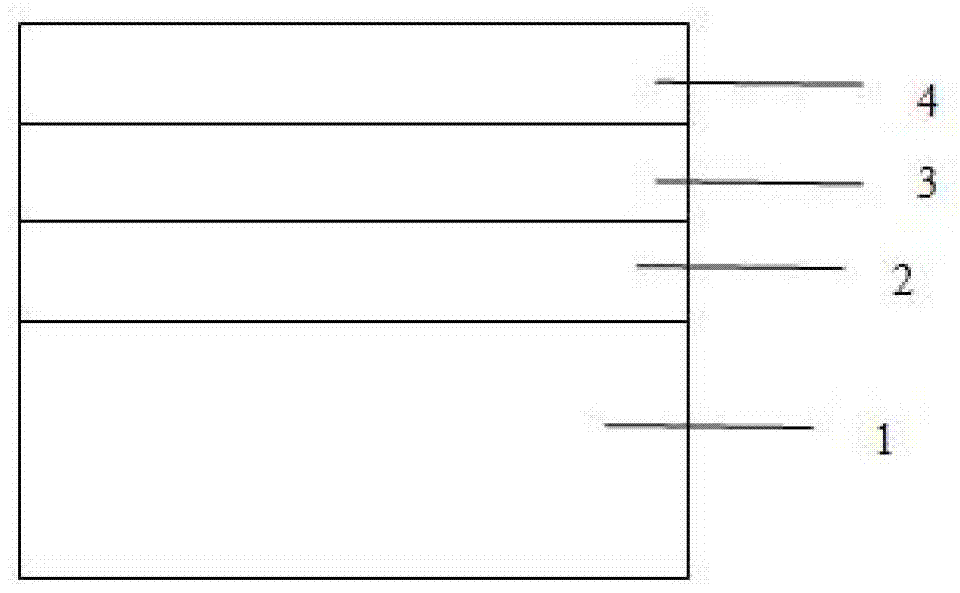

[0029] like figure 1 A high-concentration N-type doped thin germanium material on the insulating layer is shown, and the structure of the high-concentration N-type doped thin germanium material on the insulating layer is silicon substrate 1 from bottom to top, preventing N-type impurity atoms Buried SiO diffused into Si substrate 2 2. N-type doped germanium film 3 and SiO produced by oxidation 2 Layer 4, the buried SiO 2 2 has a thickness of 200nm, and the thickness of the N-type doped germanium film 3 is 30nm; the doping element in the N-type doped germanium film 3 is arsenic, and the concentration of the doping element is 10 17 cm ‐3 .

Embodiment 2

[0031] likefigure 1 A high-concentration N-type doped thin germanium material on the insulating layer is shown, and the structure of the high-concentration N-type doped thin germanium material on the insulating layer is silicon substrate 1 from bottom to top, preventing N-type impurity atoms Buried SiO diffused into Si substrate 2 2. N-type doped germanium film 3 and SiO produced by oxidation 2 Layer 4, the buried SiO 2 2 has a thickness of 400nm, the thickness of the N-type doped germanium film 3 is 20nm, the doping element in the N-type doped germanium film 3 is phosphorus, and the concentration of the doping element is 10 18 cm ‐3 .

Embodiment 3

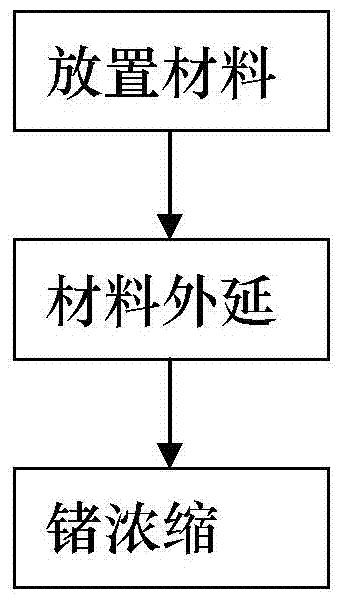

[0033] like figure 2 A method for manufacturing a high-concentration N-type doped thin germanium material on an insulating layer includes the following steps:

[0034] Step 1) placing materials: put in SOI substrate, the SOI substrate is silicon substrate, buried layer SiO2 from bottom to top 2 and top-layer silicon; the top-layer silicon is N-type doped silicon; the doping element of the N-type doped silicon is phosphorus atoms; the doping concentration of the phosphorus atoms is 4.0×10 19 cm -3 ;

[0035] The buried SiO 2 The thickness is 400nm, the thickness of the N-type doped silicon is 40nm, the N-type doping is obtained by ion implantation, the implanted ions are phosphorus ions, the implantation energy is 32Kev, and the implantation dose is 5x10 14 cm -2 , corresponding to a doping concentration of 4.0x10 19 cm -3 .

[0036] Step 2) material epitaxy: epitaxial germanium-silicon alloy thin film and Si cover layer successively on the top layer silicon of SOI sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com