Equipment for the mechanical separation of oil and bitumen from gas condensates

A condensate and oil separation technology, applied in liquid separation, gas processing condensate, separation methods, etc., can solve the problems of volume space and cost of slow gas condensate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

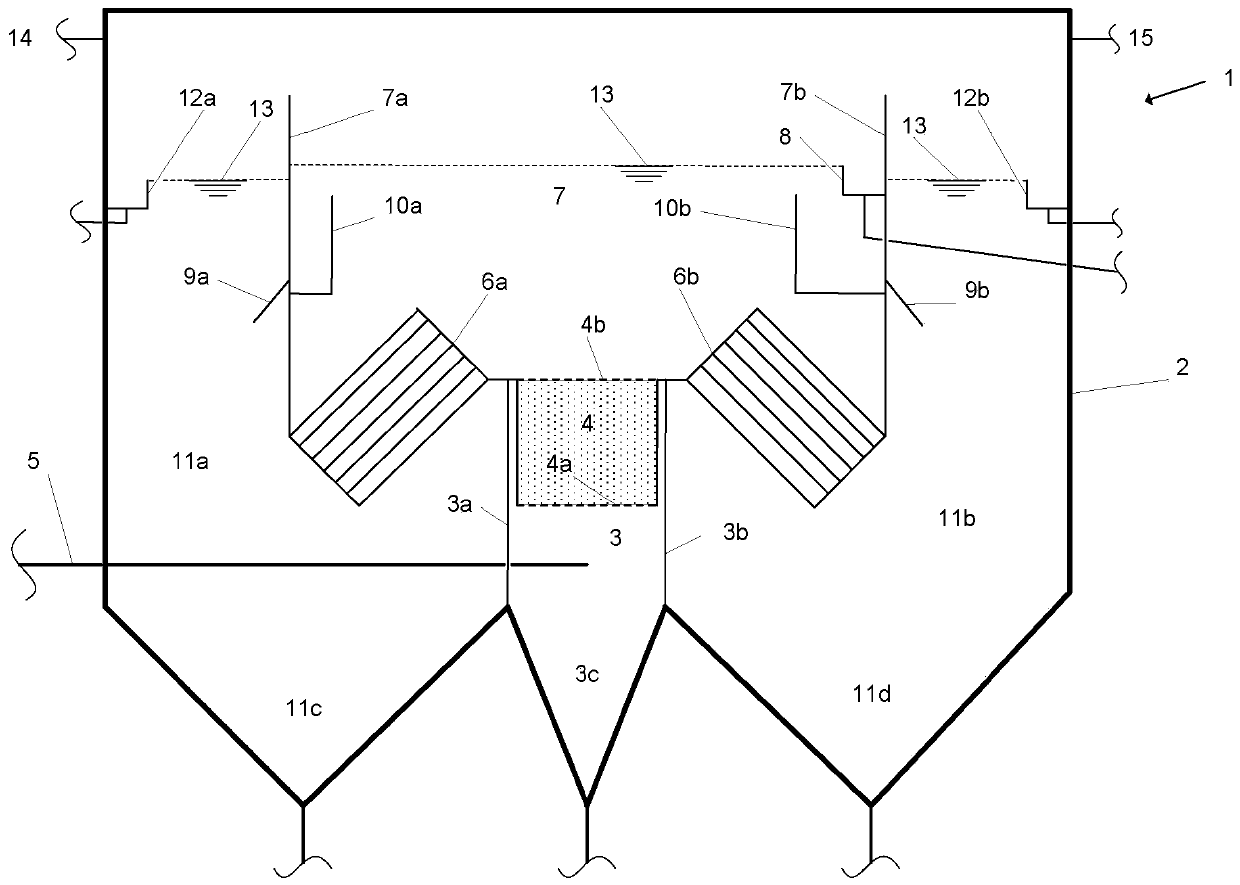

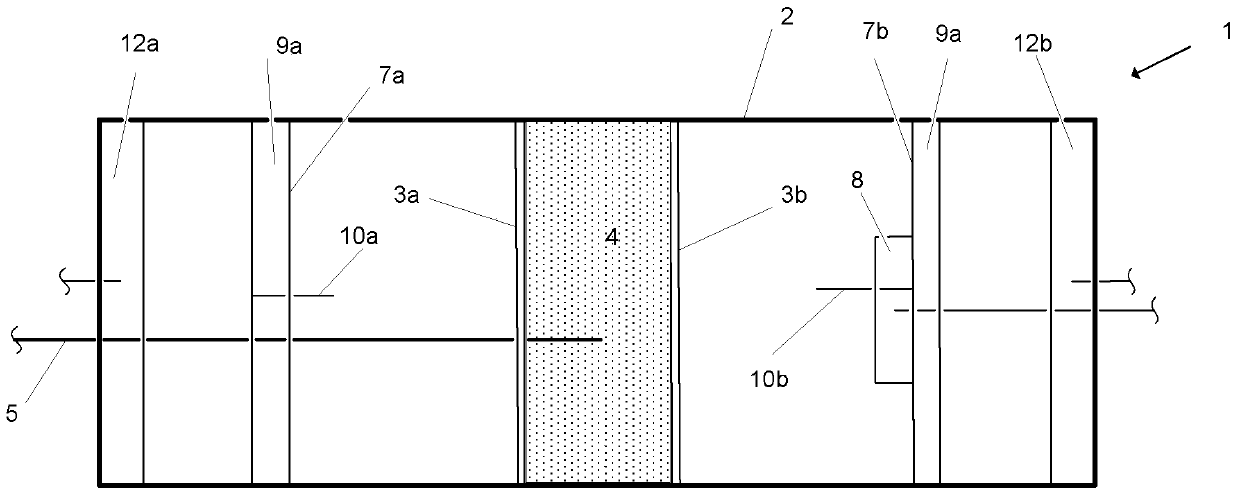

[0035] The accompanying drawings show:

[0036] A device 1 comprising an outer tank 2 having a rectangular cross-section and internal fittings present therein, the device 1 will be described in detail hereinafter;

[0037] Partitions 3a, 3b forming an inlet chamber 3 into which gas condensate to be cleaned is fed via a feed conduit 5;

[0038] a coalescent tank 4, filled with metallurgical coke, and the upper side 4b and the lower side 4a of the coalescent tank 4 are perforated;

[0039] Parallel or corrugated plate separators 6a, 6b;

[0040] Partitions 7a, 7b which separate the oil separation chamber 7 from the remaining tank space;

[0041] Oil collecting plates 9a, 9b mounted on the partitions 7a, 7b with one long side;

[0042] Conduits 10a, 10b, which guide the oil collected under the oil collecting plate, pass through openings, not shown in the figures, in the corresponding partitions into the oil separation chamber 7 slightly below the liquid level 13;

[0043] an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com