Automatic sorting device for tableware

An automatic sorting and tableware technology, which is applied in the fields of packaging, tableware sorting, automatic packaging, and sorting of disposable disinfection tableware. It can solve the problems of high noise in the working environment, high work intensity of workers, and re-contamination of tableware. Achieve low work efficiency, achieve standardized operations, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

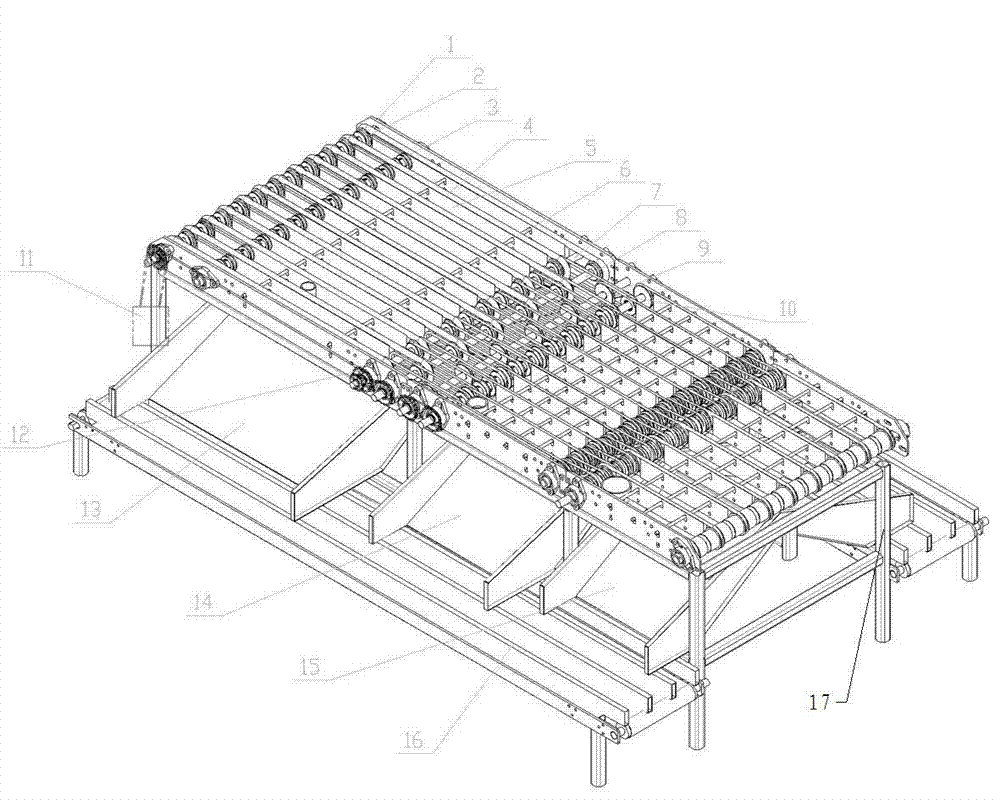

[0020] refer to figure 1 , the tableware automatic sorting part provided by the present invention adopts the following technical solutions to realize: it includes a conveyor side plate; a buffer conveyor belt; a buffer pulley; a conveyor belt; Motor; transmission sprocket; glass cup guide; small bowl guide; large bowl guide; isolation sorting conveyor.

[0021] The principle is that according to the different shapes and sizes of different tableware, the sorting method is adopted one by one. The glass cups are dropped first in the first sorting, the small bowls are dropped in the second sorting, the large bowls are dropped in the third sorting, and finally lef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com