Smooth sand adding casting mechanical device

A kind of mechanical equipment and sand casting technology, applied in the field of smooth sand casting machinery and equipment, can solve problems such as blockage of sand feeding channels, etc., and achieve the effects of cost reduction, maintenance cost reduction, and good sand feeding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

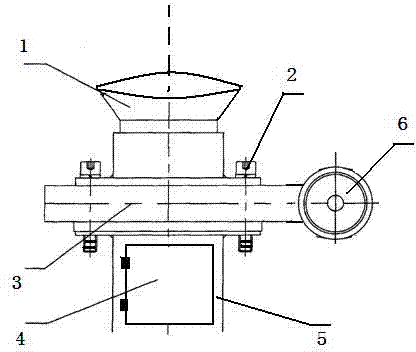

[0012] This embodiment provides an unimpeded sand casting mechanical equipment, characterized in that: the unimpeded sand casting mechanical equipment includes sand bucket (1), fastening screw (2), valve (3), sand inlet ( 4), lower sand channel (5), reducer (6);

[0013] Among them: the lower sand channel (5) connected with the lower sand bucket (1), a valve (3) is arranged in the lower sand channel (5), and a sand inlet (4) is provided under the lower sand channel (5). (3) is equipped with a fastening screw (2), and one side of the valve (3) is also provided with a reducer (6).

[0014] Four fastening screws (2) can be installed, the valve (3) is flange type, and the speed reducer (6) is eddy current type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com