Edge and chamfer accurate grinding device of cylindrical glass optical lenses and method thereof

A glass lens, cylindrical technology, applied in the field of cylindrical glass lens edge chamfering fine grinding device, can solve the problems of low processing efficiency, complicated operation, etc., achieve the effect of reducing labor intensity, improving consistency, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

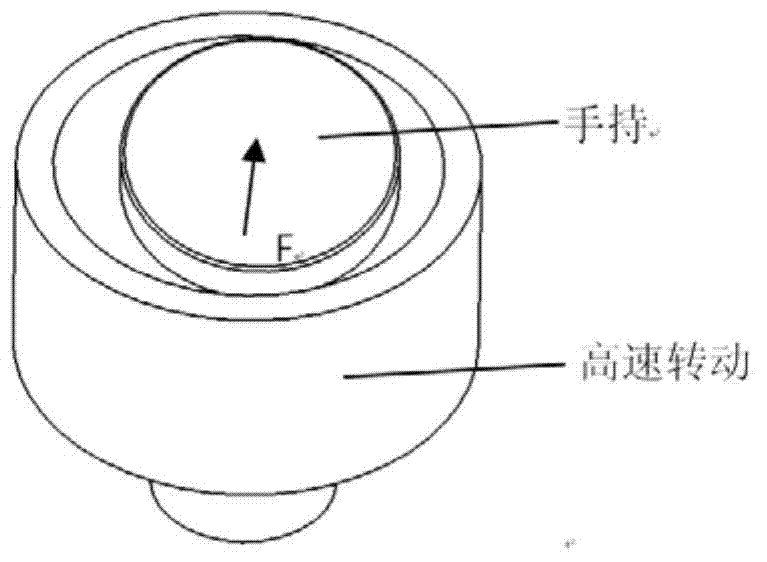

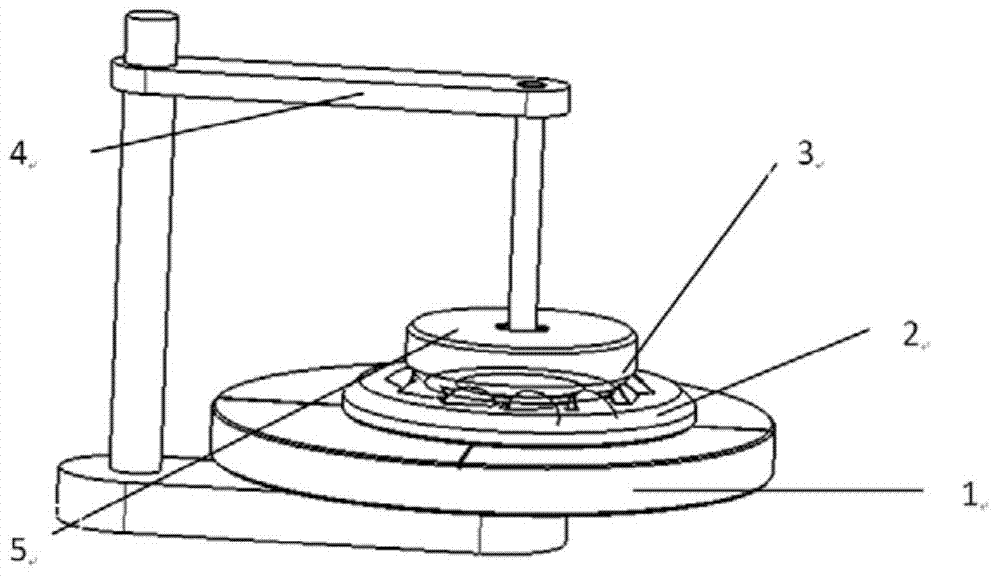

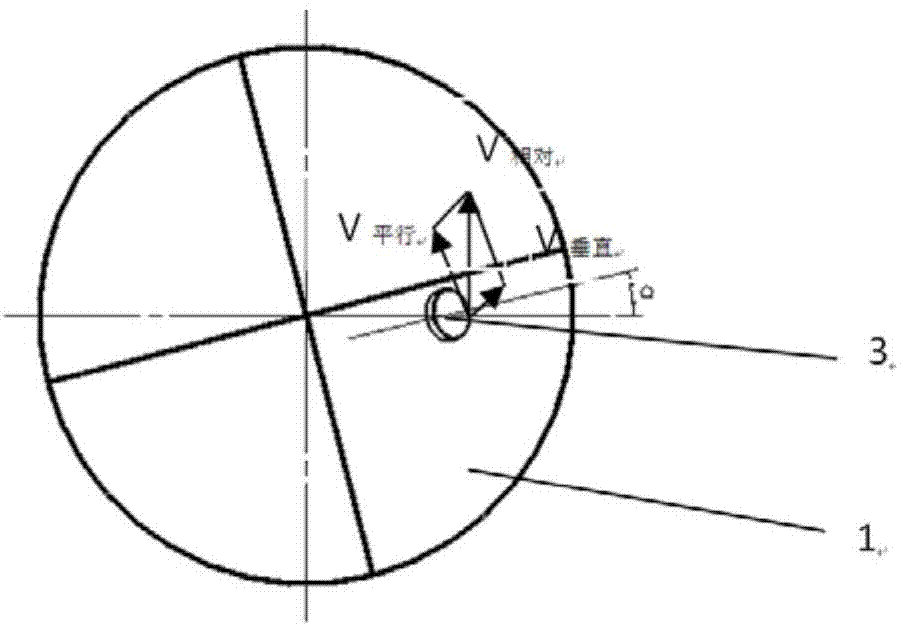

[0018] see figure 2 , which is a structural schematic diagram of the edge chamfering fine grinding device for cylindrical glass lenses of the present invention. The edge chamfering fine grinding device of the cylindrical glass lens of the present invention comprises a fine grinding disc 1 , a chamfering positioning tool 2 , a swing arm 4 , a toggle wheel 5 and a base 6 . Wherein, the fine grinding disc 1 is assembled on the base 6 and driven by a motor to rotate around its own rotation center at high speed. The chamfering positioning tool 2 is a disc-shaped fixture used for positioning the chamfering angle of the cylindrical glass lens 3 and constraining its movement. Swipe up. The cylindrical glass lens 3 is placed in the positioning groove in the chamfering positioning tool 2, and can rotate around its own rotation center, and follow the chamfering positioning toolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com