Process method for preparing synthesis gas using zero-carbon or negative-carbon emission system

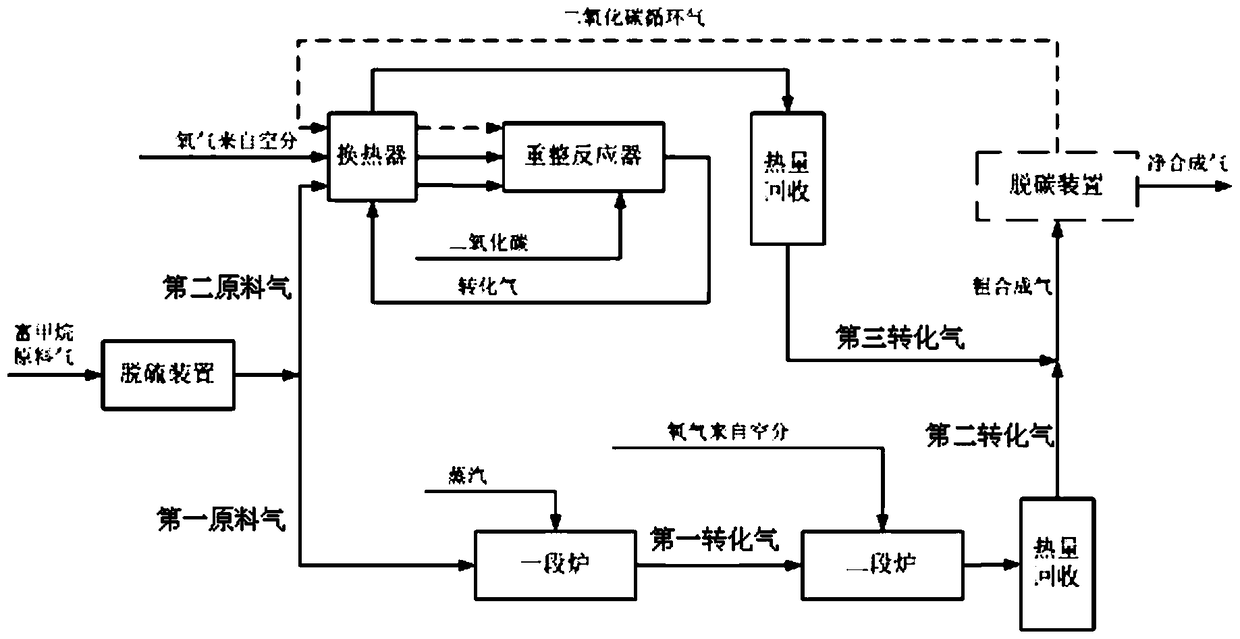

A technology of an emission system and a process method, which is applied in the field of synthesis gas preparation, can solve the problems of complex process system control, low hydrogen and carbon content of synthesis gas, inability to directly use methanol for synthesis or Fischer-Tropsch process, etc., so as to simplify the control conditions of the process system and realize the Zero or negative carbon emissions, the effect of reducing greenhouse gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Refined desulfurized natural gas (sulfur content <1ppm) with a flow rate of 182.64kmol / hr, a pressure of 4.2MPa, and a temperature of 360°C is divided into two streams by a splitter, one with a flow rate of 100kmol / hr, demethane-steam reforming (first feed gas), another demethane-carbon dioxide reforming reactor (second feed gas).

[0037] After the first raw material gas is mixed with medium-pressure steam (steam) with a flow rate of 300kmol / hr, a pressure of 4MPa and a temperature of 370°C, it enters the convection section of the external heating type first-stage furnace after heat exchange, and the temperature rises to 600°C before entering the first-stage furnace A reforming reaction takes place, resulting in a first reformed gas. Among them, the operating pressure of the first stage furnace is 4MPa, the outlet temperature is 708°C, and the molar content of residual methane is 12.5%.

[0038] Pure oxygen from air separation, with a flow rate of 39 kmol / hr, undergoe...

Embodiment 2

[0042] The flow rate is 157.09kmol / hr, the pressure is 3.8MPa, and the temperature is 358℃. The finely desulfurized coke oven gas (sulfur content <1ppm) has a hydrogen molar content of 58% and a methane molar content of 28.7%. Units, one with a flow rate of 100kmol / hr, demethane-steam reforming (first raw material gas), and another demethane-carbon dioxide reforming unit (second raw material gas).

[0043] Since the methane content in the first raw material gas is relatively low, after mixing with medium-pressure steam with a flow rate of 85 kmol / hr, a pressure of 4 MPa, and a temperature of 370 °C, the temperature rises to At 600°C, it enters the first-stage furnace for reforming reaction to obtain the first reformed gas. Among them, the operating pressure of the first stage furnace is 4MPa, and the outlet temperature is 750°C. The molar content of residual methane was 12.8%.

[0044] Pure oxygen from air separation, with a flow rate of 14.5kmol / hr, undergoes combustion rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com