A Methanol Synthetic Reaction Gas Used in the Heating Process of Methanol Pre-rectification Tower

A pre-distillation tower and methanol synthesis technology, which is applied in the field of methanol preparation, can solve the problems of air-cooling power consumption, large cooling water consumption, and a large amount of low-level heat that cannot be used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The methanol synthesis reaction gas of this embodiment is used in the heating process of the methanol pre-rectification tower as follows:

[0027] The temperature of the methanol synthesis reaction gas entering the reboiler of the methanol pre-rectification tower is 85°C (calculated as 200,000 tons / year methanol) and the pressure is 6.8MPa (A).

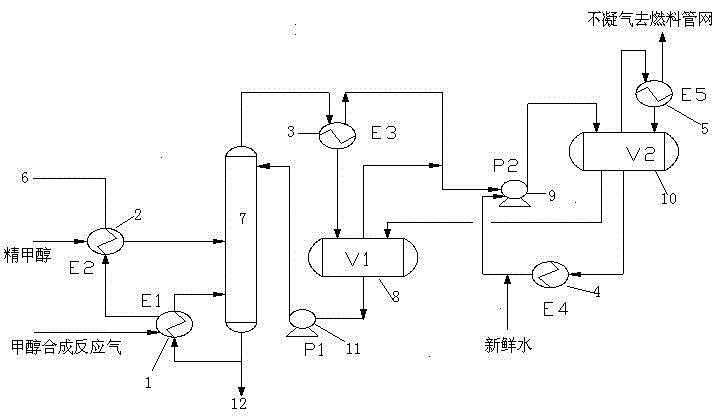

[0028] If the process is like figure 1 As shown, the methanol synthesis reaction gas temperature is 85°C, and the temperature is about 70°C after the methanol pre-rectification tower reboiler E1 heat exchange, and then the methanol pre-rectification tower feed heat exchanger E2 heat exchange, the methanol synthesis reaction gas temperature Down to 67 ℃ to the water cooler. The crude methanol enters the feed heat exchanger E2 of the methanol pre-rectification tower and is heated at a temperature of about 63°C, and then enters the methanol pre-rectification tower for rectification T. The pressure at the top of the methanol pre-rectif...

Embodiment 2

[0031] The methanol synthesis reaction gas of this embodiment is used in the heating process of the methanol methanol pre-rectification tower as follows:

[0032] The temperature of the methanol synthesis reaction gas entering the reboiler of the methanol pre-rectification tower is 81°C (calculated as 100,000 tons / year of methanol) and the pressure is 5.2MPa (A).

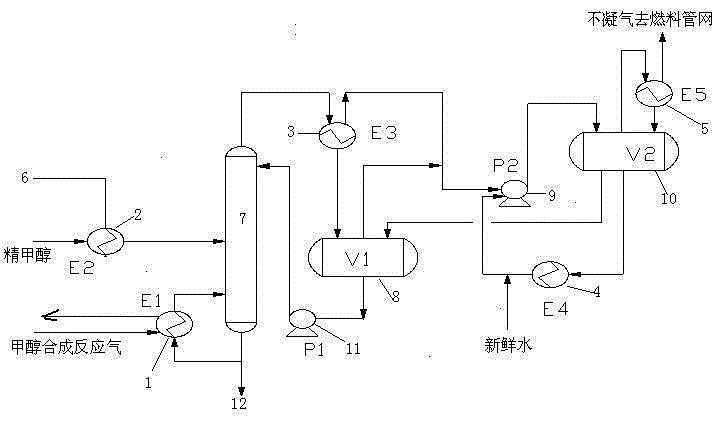

[0033] If the process is like figure 2 As shown, the methanol synthesis reaction gas temperature is 81°C, and the temperature is about 67°C after the heat exchange of the methanol pre-rectification tower reboiler E1, and then goes to the water cooler. The crude methanol enters the feed heat exchanger E2 of the methanol pre-rectification tower and is heated at a temperature of about 67°C, and then enters the methanol pre-rectification tower T for rectification. The pressure at the top of the methanol pre-rectification tower is controlled at 0.065MPa (A), the pressure at the bottom of the methanol pre-rectification tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com