Inlet and discharge combination valve for standard metal gauge

A standard metal measuring device and valve technology, applied in the field of measuring instruments, can solve the problems of inaccuracy of detection data and detection efficiency of serial leakage, and achieve the effect of solving serious errors in detection data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

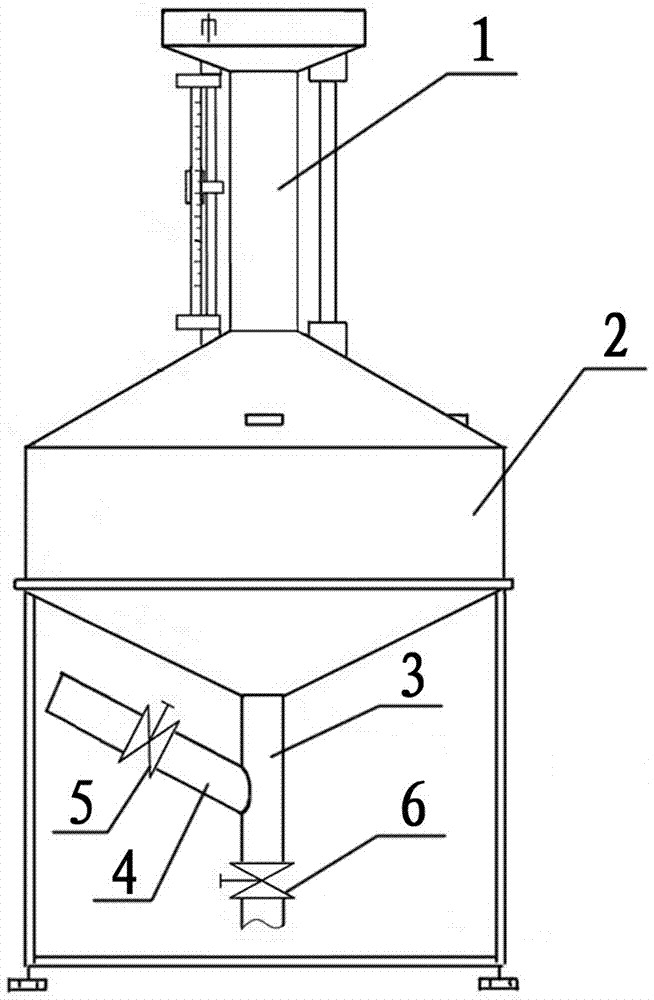

[0031] Such as figure 1 As shown, the combined liquid inlet and discharge valve of the standard metal measuring instrument provided by the present invention includes a main pipe 3 , a liquid inlet branch pipe 4 , a liquid inlet valve 5 and a liquid discharge valve 6 . A standard metal gauge includes a barrel 2 and a gauge neck 1 . The barrel body 2 includes an upper cone, a middle cylinder and a lower cone. The upper cone and the lower cone have a symmetrical structure. The metering neck 1 is a vertical tubular structure, and the lower end of the metering neck 1 is connected to the opening end of the cone on the barrel body 2 .

[0032] The main pipe 3 is arranged in a vertical state, and the upper port of the main pipe 3 is shaped on an external thread, and the upper port of the main pipe 3 is threadedly connected with the opening of the cone below the staving 2 (this opening is the bottom interface of the standard metal gauge).

[0033] One end of the liquid inlet branch pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com