Sleeving method for multi-layer screw-type heat exchanging tube bundles

A heat exchange tube bundle and spiral technology, which is applied in the field of thermal engineering, can solve the problems of scratches on the surface of supporting parts, stuck heat exchange tubes, long installation period, etc., and achieve the effect of avoiding scratches and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

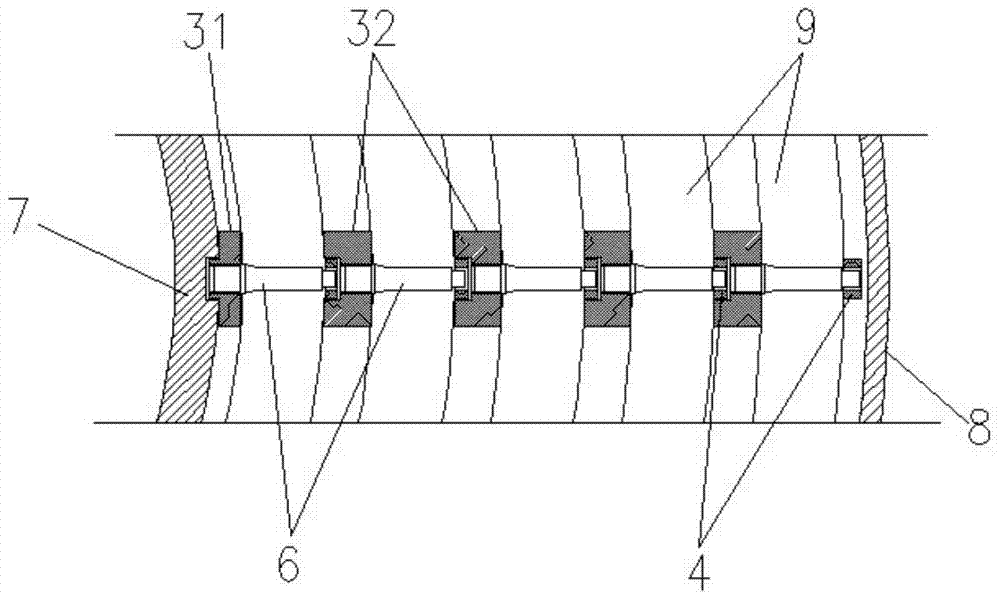

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

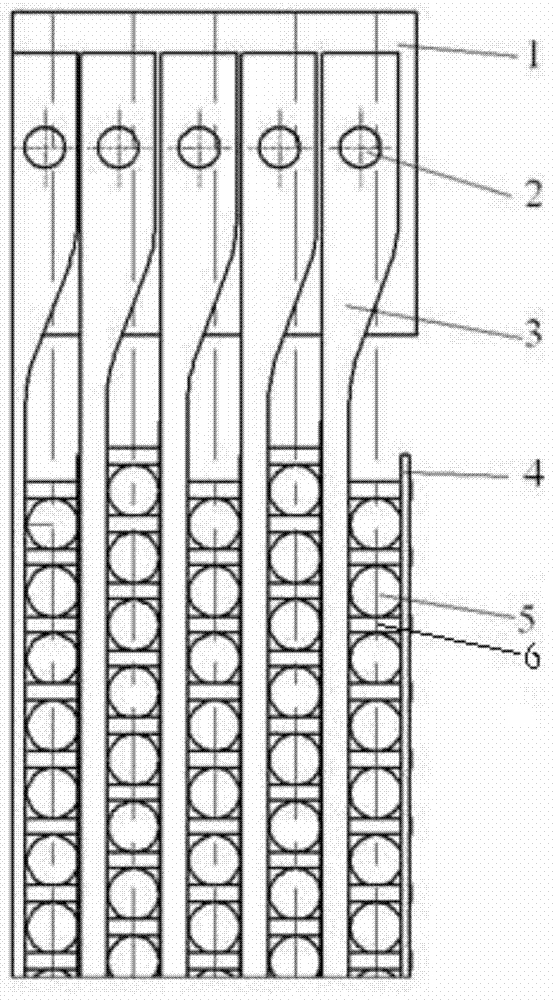

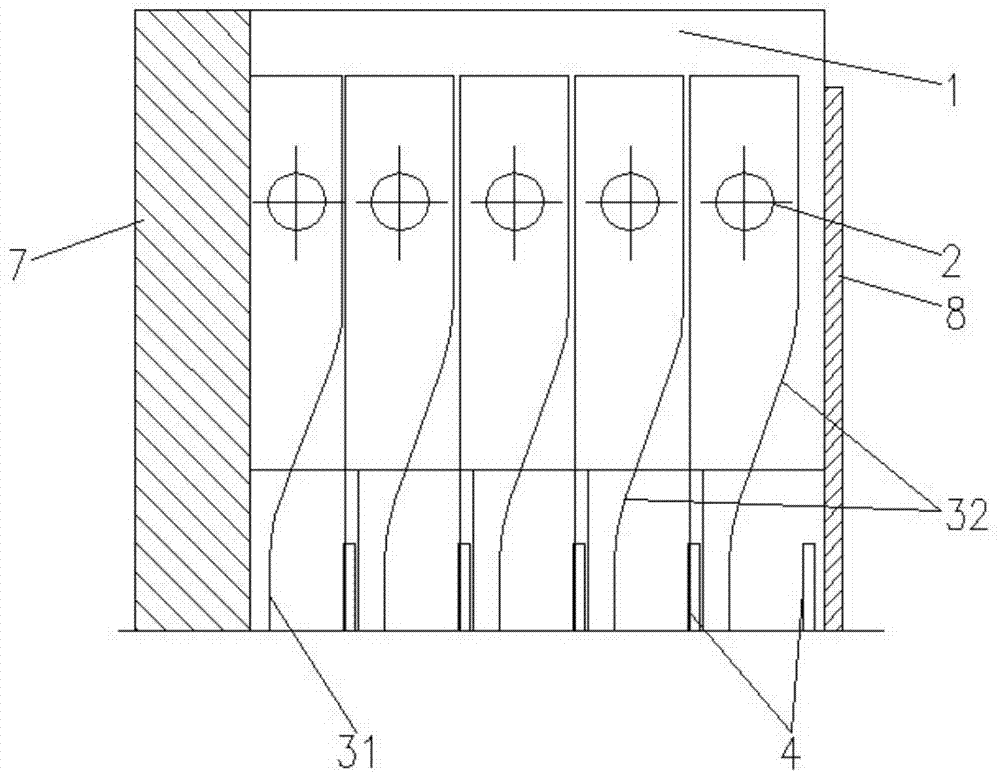

[0033] The spiral heat exchange tube bundle is used to isolate the heat exchange medium of the primary circuit from the heat exchange medium of the secondary circuit, and withstand the pressure difference between the heat exchange medium of the primary circuit and the heat exchange medium of the secondary circuit. Since the high temperature gas-cooled reactor steam generator is a once-through steam generator, the length of each heat exchange tube is very long. In order to reduce the structural size of the steam generator as much as possible, most of the heat exchange tube bundles adopt a spiral structure. The layer spiral tube bundle is formed by winding multiple heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com