Test tool for inner-high-pressure-shaped complicated automobile tube beams

A complex technology of internal high pressure forming, which is applied in the direction of measuring devices, instruments, and mechanical devices, etc., can solve the problems of welding quality, the same, and the high cost of three-coordinate inspection, and achieve the effect of wide application and guaranteed welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

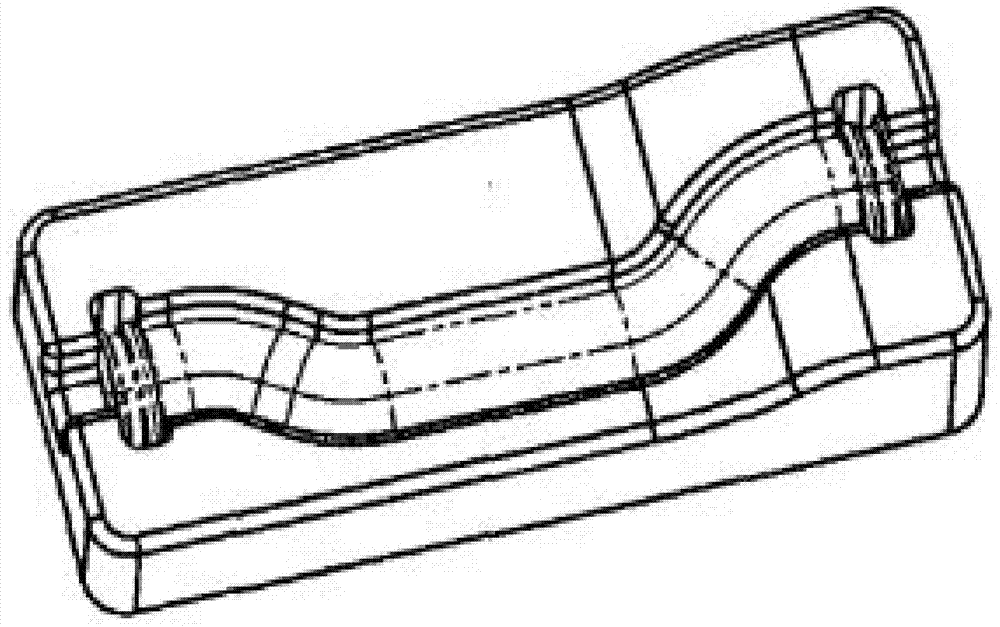

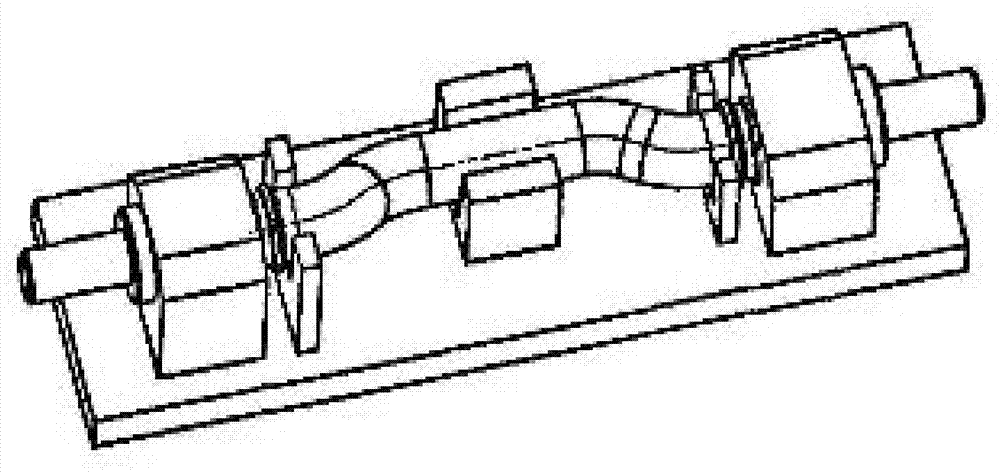

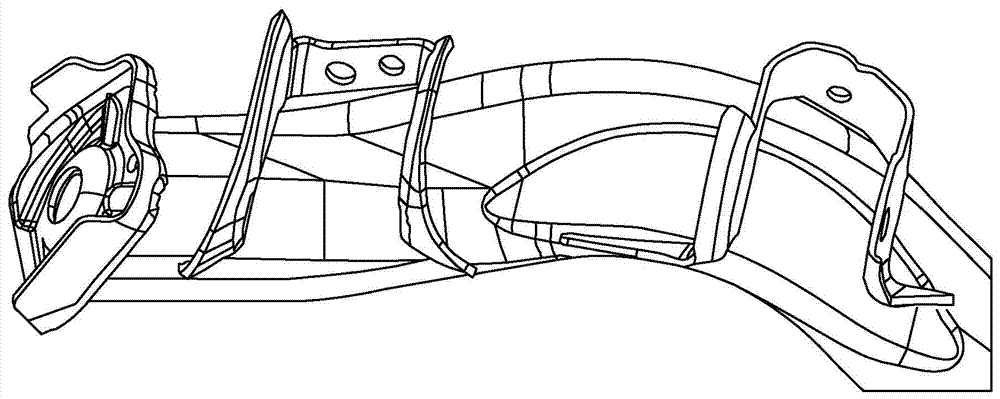

[0026] Such as Figure 4 and Figure 5 As shown, the present embodiment is a inspection tool for internally high-pressure formed complex automobile pipe beams, including a coordinate base 1 made of No. 45 steel, and several U-shaped pillars 2 are arranged on the coordinate base 1. The trajectory of the arrangement of the U-shaped pillars is consistent with the design shape of the pipe to be detected, and the pipe to be inspected is placed on the above-mentioned U-shaped pillar 2 during detection.

[0027] At least one special-shaped surface detection pillar 3 is also placed on the coordinate base 1, which is arranged on the side of the pipe to be detected and parallel to the pipe 4, and is threaded or pinned on the special-shaped surface detection pillar 3. The special-shaped surface detection mold 5 is installed, and the above two installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com