Underground pipeline testing method based on strain membranes

A technology of strained film and testing method, which is applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measuring device, material resistance, etc., can solve the problems of inconvenient maintenance for management personnel, inability to locate immediately, reduction of induction speed and induction effect, etc., to achieve The effect of reducing pipeline maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

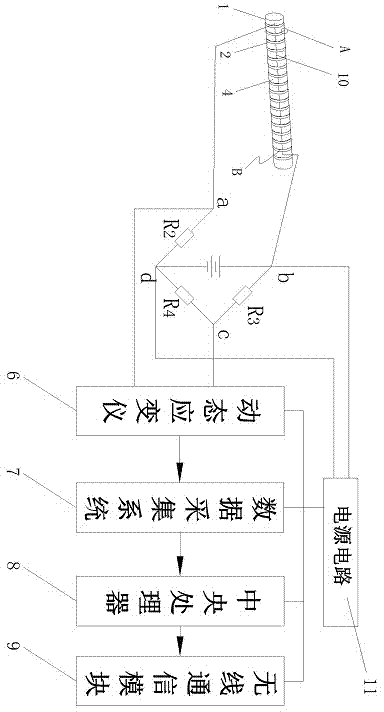

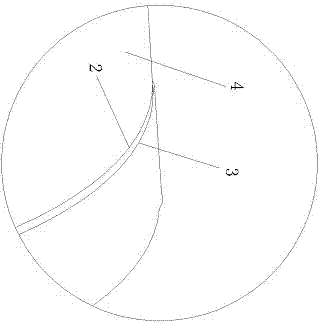

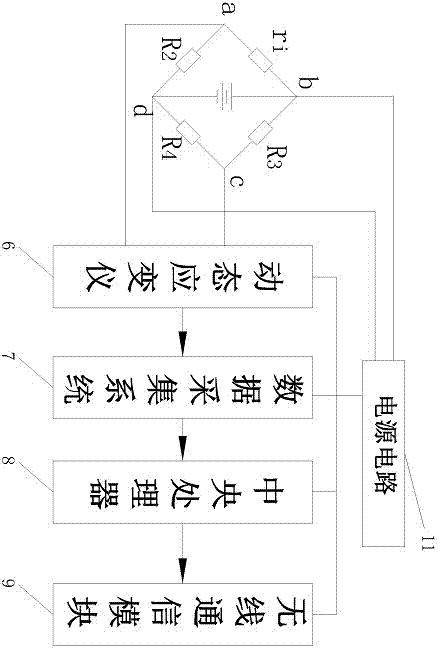

Embodiment 2

[0056] refer to Figure 4 As shown, this embodiment is basically the same as Embodiment 1, except that every n ring-shaped strained thin films 2 are connected in parallel through wires 10 to form a strained thin film group B. The equivalent circuit is also the same as that of the first embodiment. The equivalent resistance of the strained film group B is Ri, and this equivalent circuit is connected to the b terminal of the bridge circuit 5. When the pipeline 1 is broken or slightly deformed, the corresponding annular strained film 2 is slightly deformed or broken, so that The equivalent resistance ri of the strained film group changes, and the bridge circuit converts the resistance change of the strained film group ri (i=1~3) into a voltage change, and the voltage change is amplified and filtered by the dynamic strain gauge 6 to obtain The signal prototype, the signal prototype is sent to the data acquisition system for data storage, and sent to the central processing unit 8,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com