Resonant cavity for frequency-selecting 355nm ultraviolet laser in optical fiber end surface pumping Brewster angle cavity

An ultraviolet laser, fiber end face technology, used in lasers, laser parts, phonon exciters, etc., can solve the problem of insufficient stability of the resonator, ensure the length, improve the stability and service life, and ensure a single frequency laser. output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

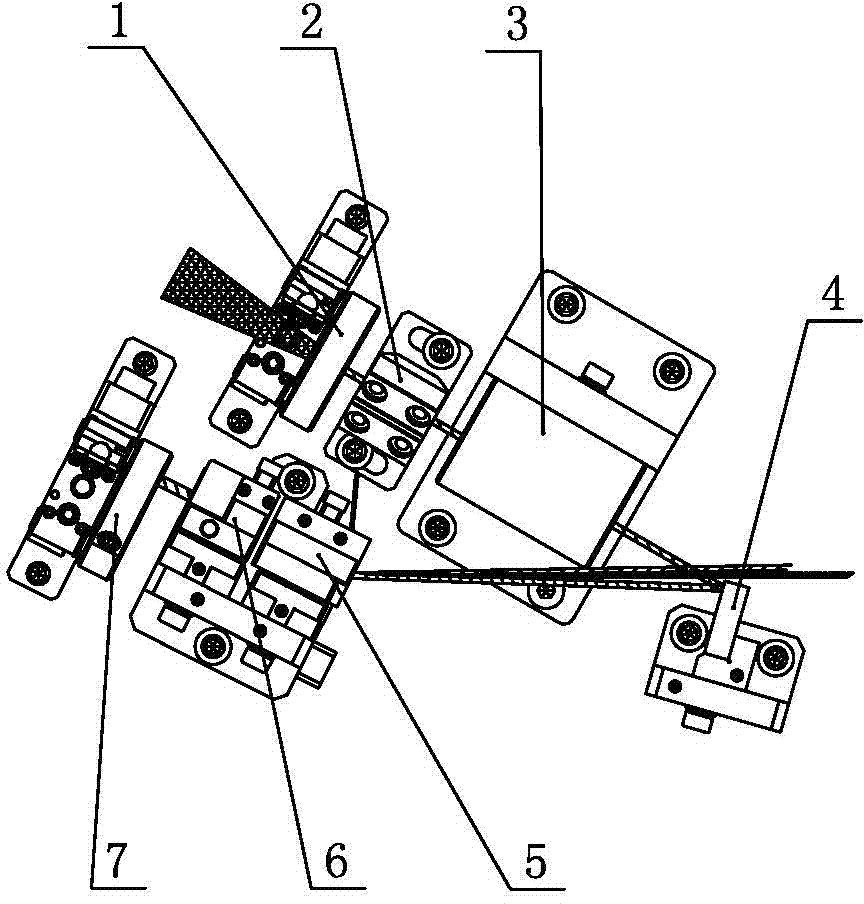

[0015] As shown in the figure: the resonant cavity in the embodiment is used on the frequency-selective 355nm ultraviolet laser in the fiber end-pumped Brewster angle cavity, which is mainly composed of a front mirror 1, a YVO4 crystal 2, an acousto-optic Q switch 3, The turning mirror 4, the triple frequency LBO crystal 5, the plano-convex front double frequency LBO crystal 6 and the rear mirror 7 are composed of parts.

[0016] Such as figure 1 As shown, the front mirror 1, YVO4 crystal 2, acousto-optic Q switch 3 and turning mirror 4 are arranged sequentially from back to front along the exit direction of the 808nm pump laser; the 808nm pump laser enters through the front mirror 1 and Excite the YVO4 crystal 2 to generate 1064nm laser; the 1064nm laser enters the turning mirror 4 through the acousto-optic Q switch 3, and then refracts and exits after passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com