Fireproof suspended type automatic charging mechanism and work process thereof

An automatic charging and waterproof technology, applied in current collectors, electric vehicles, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

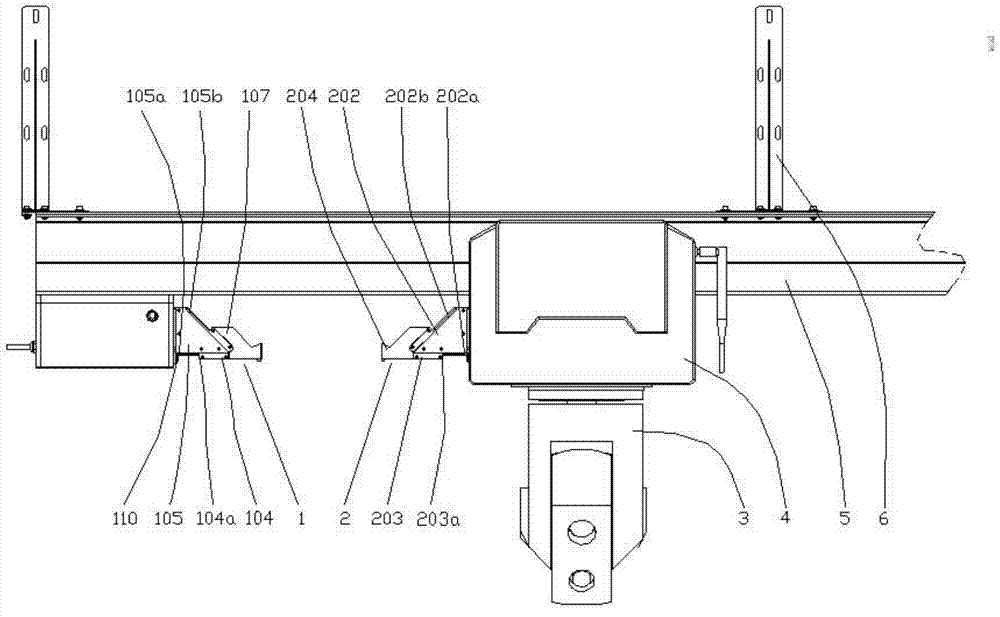

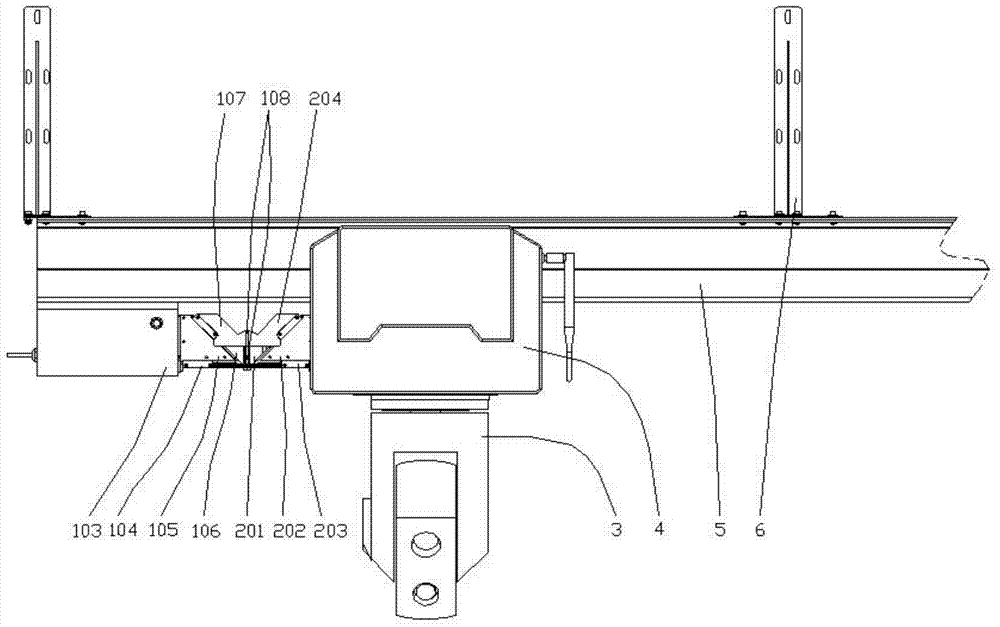

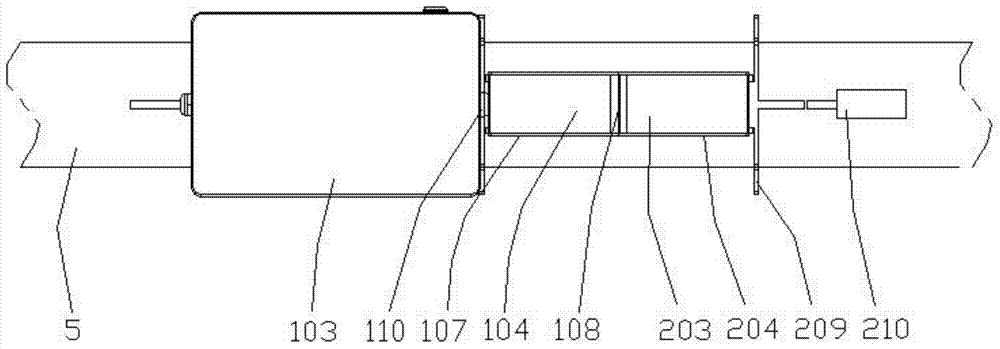

[0026] See attached figure 1 -4, the present invention includes a charging fixture 1, a charging mobile device 2, a monitoring device 3, a track machine 4, a track 5, and a track bracket 6. The charging fixture 1 is composed of a charging waterproof case 103 and a horizontal slide plate 104 for the fixture , fixed device side plate 105, fixed charging seat 106, inclined slide plate 107, waterproof sponge 108, charger assembly 109, button 110, waterproof joint 111, fixed conductive sheet 112, contact piece positioning seat 113, connecting plate 116 composition.

[0027] The charging mobile device 2 is composed of a probe positioning seat 201, a mobile device side plate 202, a horizontal slide plate 203, an inclined slide plate 204, a guide plate 205, a waterproof joint 111, a probe 207, a fastening pin 208, and a mobile d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com