Brushless direct current motor for car power-driven/gasoline mode rapid switching

A brushed DC motor, fast switching technology, applied in electric components, electrical components, electromechanical devices, etc., can solve the problem of no DC brushless motor, and achieve the effect of improving reliability, shortening axial size, and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments.

[0020] Such as Figure 1-5 As shown (when pictures are available).

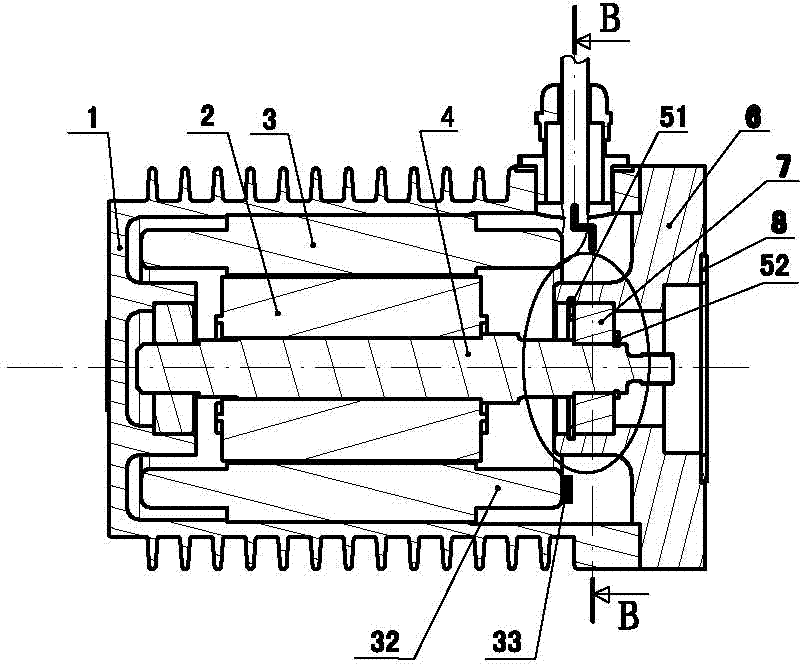

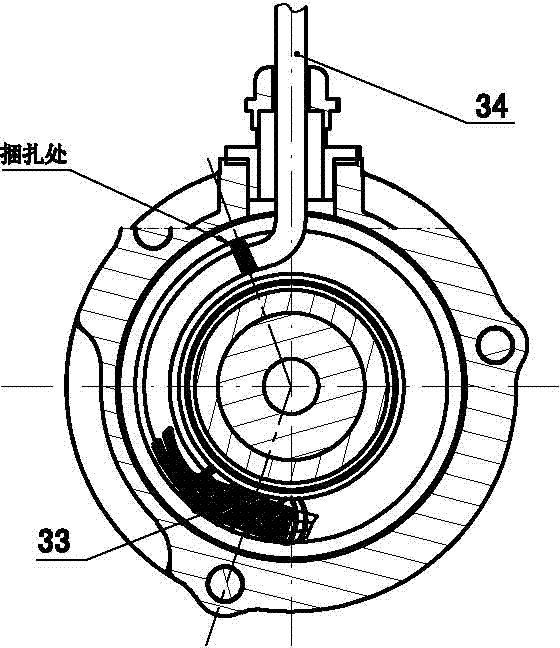

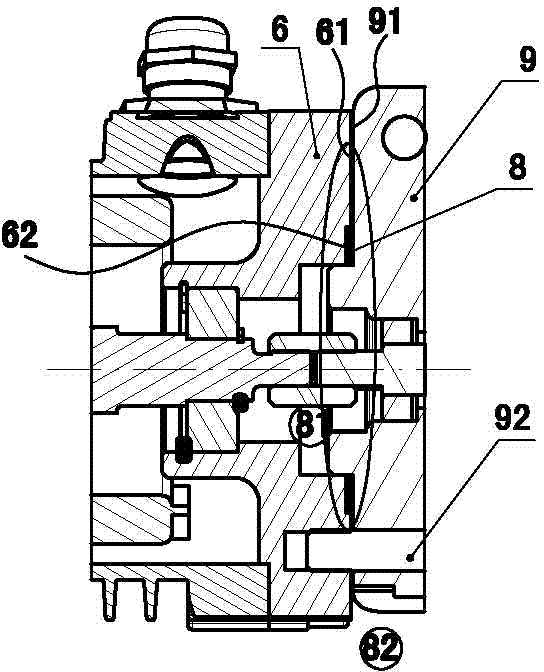

[0021] A brushless DC motor for fast switching between electric and gasoline modes of an automobile. It includes a housing 1, a rotor 2, a stator 3, a main shaft 4 and an end cover 6. The rotation 2 is fixedly mounted on a section of the main shaft 4 in the housing 1. The stator 3 is fixedly installed in the housing 1 and opposite to the rotor. The output end of the main shaft 4 is supported in the bearing 7, the bearing 7 is installed in the end cover 6, and the end cover 6 is fixed on the open end of the housing 1. The inner and outer sides of the bearing 7 are respectively positioned axially through the hole retaining ring 51 and the shaft retaining ring 52, such as figure 1 Shown; the stator coil 32 on the stator 3 is installed with a temperature sensor 33 (structure such as figure 2 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com