Raw material formula design method of paper-making reconstituted tobacco leaves extracted from stem ends alone

A technology of reconstituted tobacco leaves and separate extraction, applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problem that subjective experience does not conform to the actual production situation of reconstituted tobacco leaves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The product design goal of this embodiment is a high-grade, fragrant paper-making reconstituted tobacco leaf; the tobacco powder monomer raw materials for use include 6 types: tobacco powder A, tobacco powder B, re-roasted powder C, re-roasted powder D, stem Sign E, ash stick F, tobacco stem G;

[0061] Step 1: Determine the quality grade and category characteristics of the designed paper-making reconstituted tobacco product as a high-grade, light-flavored paper-making reconstituted tobacco. That is, the sensory evaluation of the quality grade is ≥85.

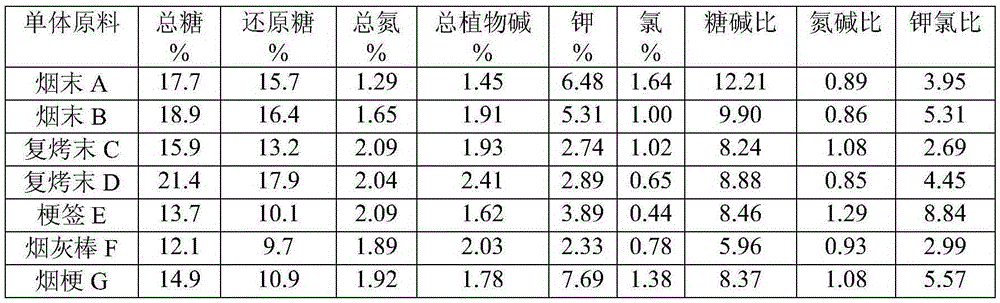

[0062] Step 2, carry out chemical analysis on 6 kinds of tobacco powder monomer raw materials and 1 kind of tobacco stem raw materials, the analysis results are shown in Table 1,

[0063] Table 1 Analysis of chemical components of tobacco powder monomer raw materials and tobacco stem raw materials

[0064]

[0065] It is generally believed that the appropriate content range of chemical components of high-quality tob...

Embodiment 2

[0083] The product design goal of this embodiment is a medium-grade, medium-flavored reconstituted tobacco leaf; the sensory quality of the medium-grade is 75-84 points; the raw materials of tobacco powder for use still include 6 types: tobacco powder A and tobacco powder B , re-roasted end C, re-roasted end D, stem stick E, ash stick F, tobacco stem G;

[0084] Steps 1 to 4 are the same as in Example 1, and the results are consistent; screen out tobacco powder A, re-roasted powder C, soot stick F and tobacco stem G

[0085] Applying the uniform design method of computer-aided design, using the uniform design table UM 9 * (9 3 ), determine the experimental scheme with 3 factors and 9 levels, as shown in Table 4. Aiming at 9 uniformly designed samples, the reconstituted tobacco leaves were reconstituted by the papermaking method reconstituted tobacco leaf production process, and the sensory quality evaluation was carried out on the reconstituted tobacco leaves produced by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com