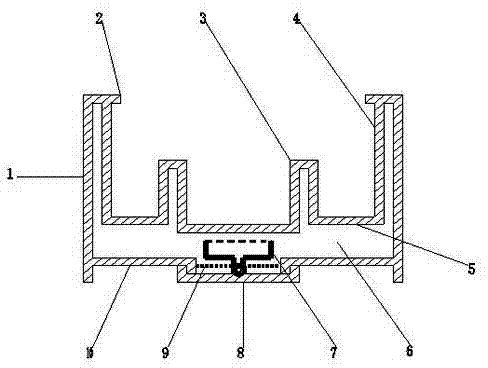

Rapid-heating efficient energy-saving pot with interlayer

A high-efficiency, energy-saving, interlayer technology, which is applied to heating devices, cooker shells/covers, cooking utensils, etc., can solve the problems of unsightly appearance, poor practicality, and non-insulation of pots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0023] Set the interlayer quick-heating high-efficiency energy-saving pot of the present invention at the required position, and connect the outer end of the heater 7 with the gas conduit (if an electric heater is used instead, it should be connected to the power supply), and then mix the clean water and hot pot according to the formula and needs The materials are put into the peripheral pot 1 and the inner pot 3 in batches or at the same time, and then the gas adjustment and the electronic ignition synchronization switch are turned to heat the heater 7 in the strong heating chamber 6. At this time, the heat energy from the strong heating chamber 6 is respectively Rise to the strong heat interlayer formed by the peripheral pot 1, the inner pot 4 and the inner middle pot 3, and in the strong heat chamber 6 and the inner wall porcelain magnetic wave of each interlayer and the strong heat, rapid heat and disappear Under the combined action of functions such as smoke and condensed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com