Solid-liquid separation device for centrifugal machine

A solid-liquid separation and centrifuge technology, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of reducing the purity of solids, working hard for staff, and reducing production efficiency, so as to improve convenience and improve work efficiency. Efficiency and the effect of reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

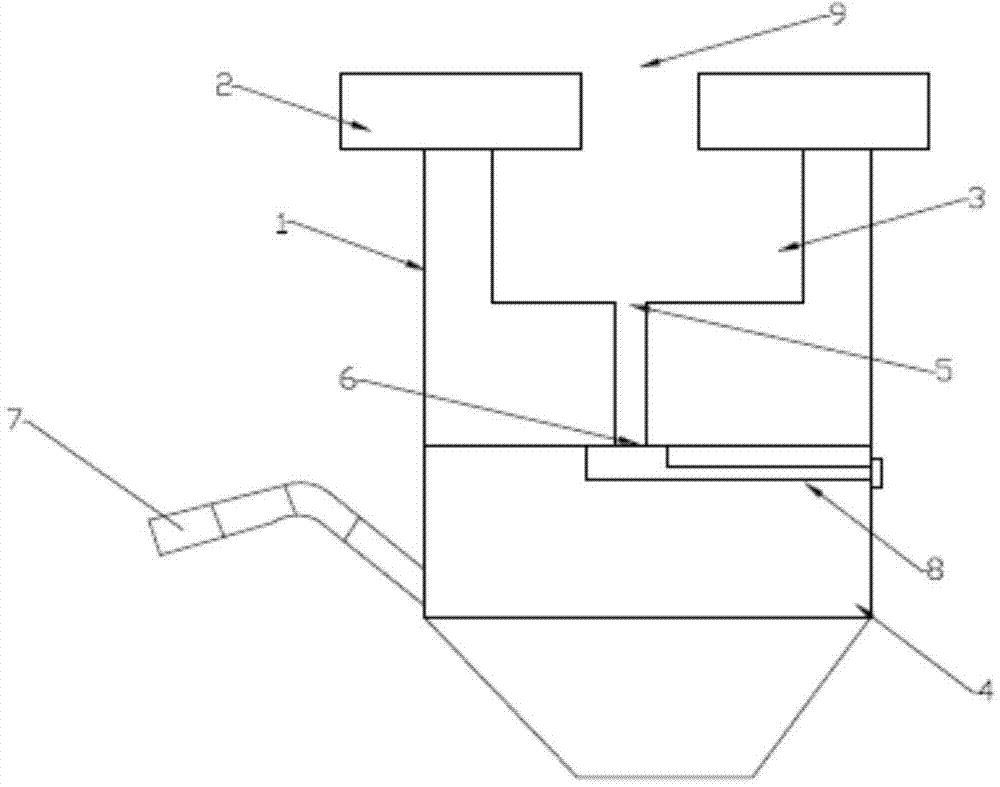

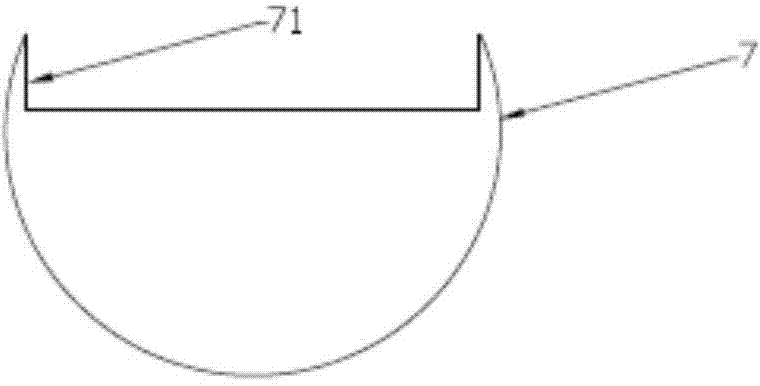

[0027] Such as figure 1 , figure 2 , image 3 As shown, this embodiment provides a solid-liquid separation device for a centrifuge, including a housing 1, a cover plate 2 buckled above the housing 1, a filter disc 3 located inside the housing 1 and connected to the bottom of the cover plate 2 And the centrifuge body 4 located at the lower end of the housing 1, the drain port 5 provided at the bottom of the filter plate 3 is connected to the liquid inlet 6 provided at the top of the centrifuge body 4 through a pipeline, and the centrifuge body 4 is also connected to a drain pipe 7. The inner wall of the drain pipe 7 is provided with a diversion groove 71 .

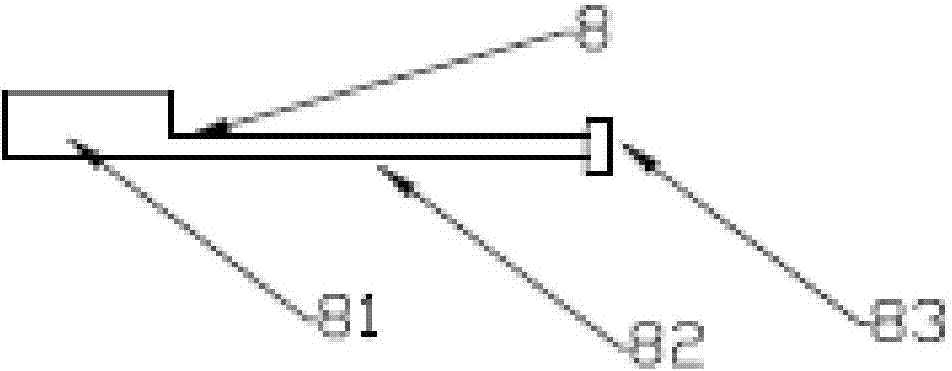

[0028] The centrifuge solid-liquid separation device also includes a movable plug 8 , and a part of the movable plug 8 is located inside the centrifuge body 4 . The movable plug 8 is composed of a plug head 81 inside the centrifuge body 4 , a fixed block 83 outside the centrifuge body 4 and a plug handle 82 connecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com