Non-tangent expansion round steel hole type and production method

A tangent and round steel technology, applied in metal processing equipment, metal rolling, metal rolling, etc., can solve the problems of not meeting the high-precision requirements and difficult to meet the needs of high-precision bar rolling, and achieve easy processing and assembly Ease of operation, high degree of automation, and simplified mechanical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

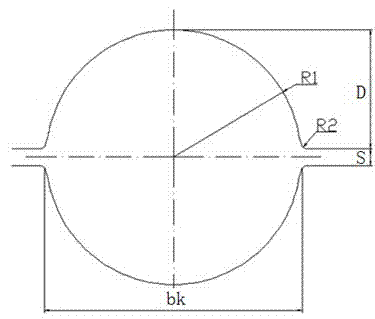

[0024] A non-tangential expansion round steel pass, which is composed of a base circle and non-tangential expansion parts located on both sides of the base circle. The specific dimensions of the base circle radius and notch width are as follows:

[0025] Base circle radius R1 =0.5×d×(1.007~1.02);

[0026] Notch width bk=d×(1.007~1.02)+(0.2~0.3);

[0027] Where: d is the nominal diameter of the round steel;

[0028] 1.007~1.02 is the coefficient of thermal expansion;

[0029] 0.2~0.3 is the groove width constant;

[0030] S is the roll gap, where S=1.5mm

[0031] D is the height of the groove bottom, D=R1-S / 2

[0032] R2 is the notch fillet radius, where R2=0.5mm.

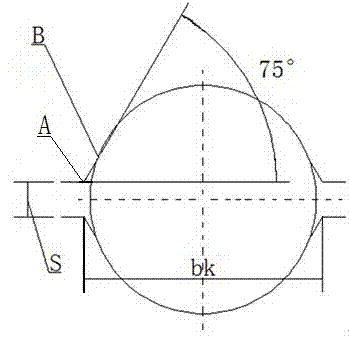

[0033] Said by figure 2 As shown, first determine the roll seam line on the base circle, the distance between the upper and lower two roll seam lines is S, determine A point on the roll seam line according to the notch width bk, and the horizontal distance between A point and the center of the base circle is S...

Embodiment 2

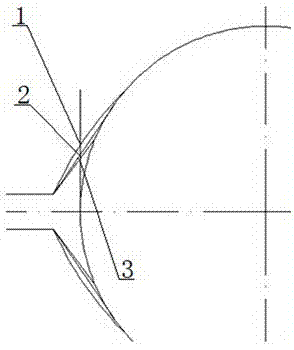

[0038] Depend on figure 2 , image 3 As shown, adopt this method to draw out the non-tangential expansion hole pattern, with embodiment 1, figure 2 It is a schematic diagram of the drawing process of the non-tangential expansion high-precision round steel pass; the traditional pass design method is used to draw the arc expansion pass and the tangential expansion pass, and this method is used to draw the non-tangential expansion pass; image 3 It is a schematic diagram of the diagonal size difference corresponding to the design methods of arc expansion pass, tangential expansion pass, and non-tangential expansion pass. In the figure, it can be known that the distance from the largest part 1 of the circular arc expansion to the base circle is the largest, and the tangent The distance from the part 2 with the largest expansion size to the base circle is second, and the distance from the part 3 with the largest non-tangential expansion size to the base circle is the smallest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com