Plate stamping feeding device

The technology of a feeding device and plate parts is applied in the stamping field of metal plate parts, which can solve the problem of high cost and achieve the effects of compact structure, saving processing cost and energy, and saving power source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

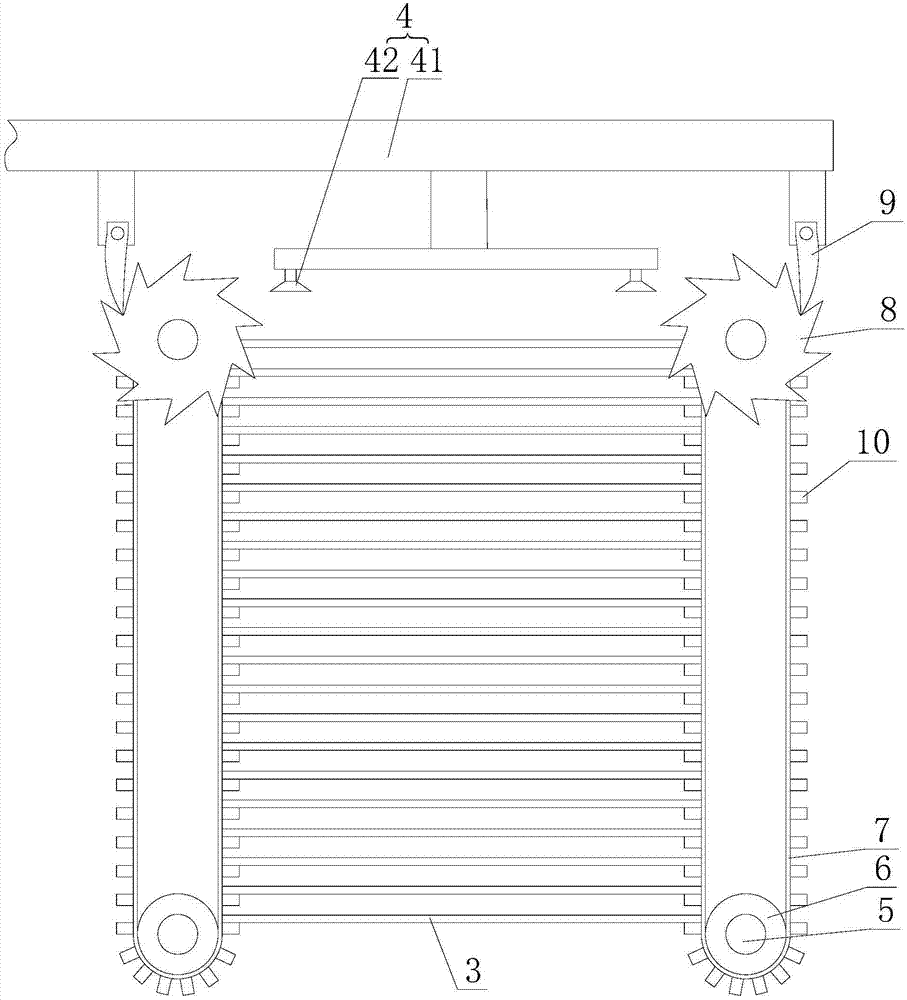

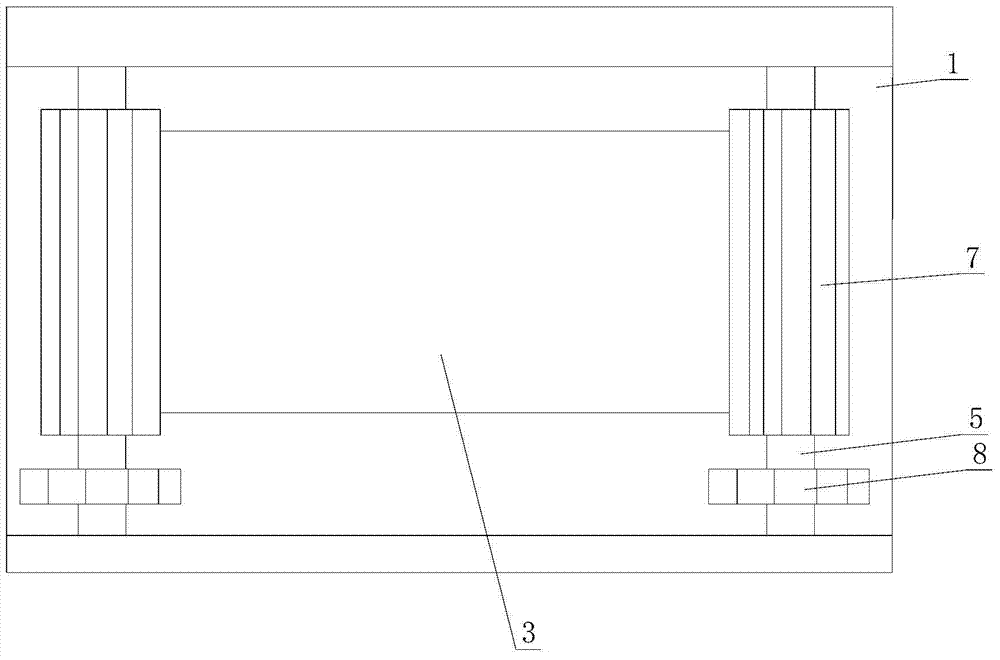

[0015] refer to figure 1 , figure 2 with image 3 , a plate stamping feeding device, including a support base 1, two sets of synchronous belt devices 2 symmetrically arranged on the support base 1, a manipulator 4 for taking a rectangular plate 3; each set of synchronous belt devices 2 It includes two upper and lower rotating shafts 5 arranged in the front and rear directions of the axis and transferred to the support base 1, two synchronous pulleys 6 respectively fixedly connected to the two rotating shafts 5, and a synchronous belt 7 arranged on the two synchronous pulleys 5. , evenly distributed on the outer surface of the synchronous belt 7 and used to support the support block 10 on one side of the plate 3; the rotating shaft 5 above the synchronous belt device 2 of each group is fixedly connected with a ratchet 8, and the manipulator 4 is connected with two left and right Drive the ratchets 9 of the two ratchets 8 respectively, the ratchet 9 on the left side is positi...

Embodiment 2

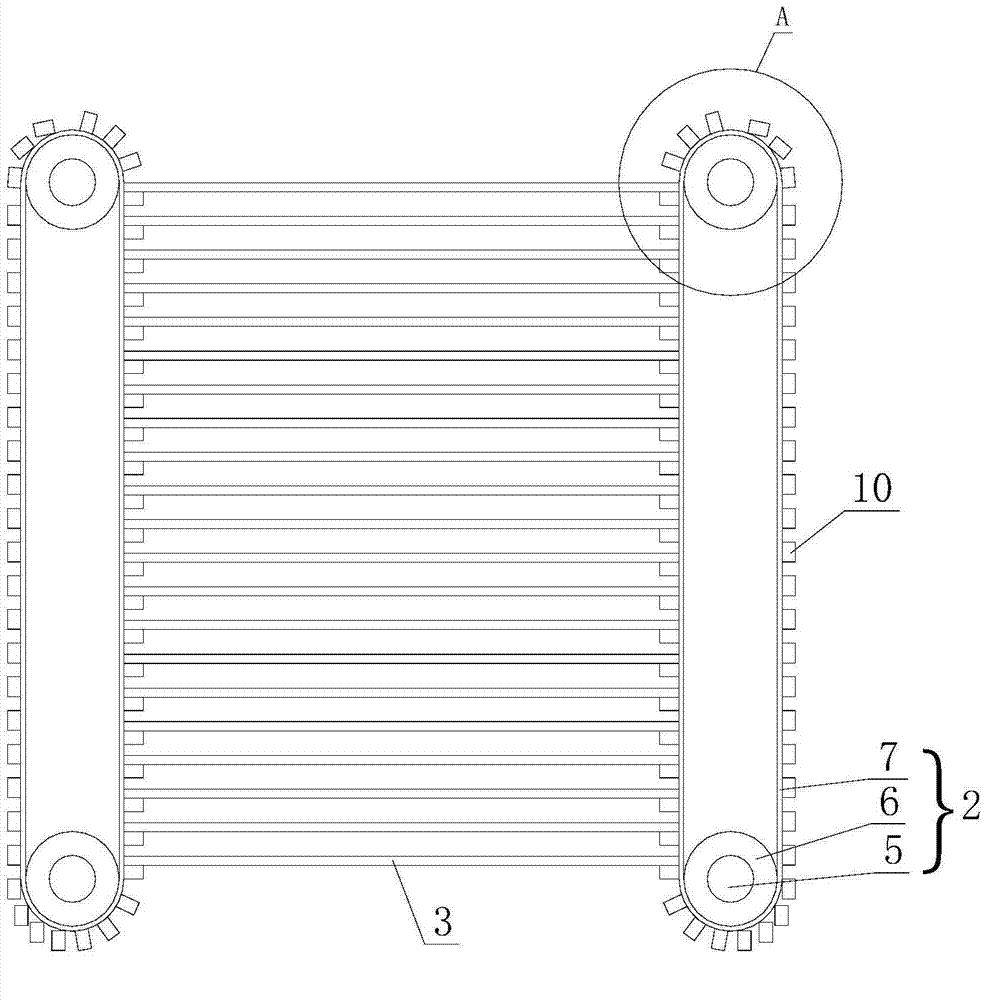

[0020] refer to Figure 4 , the difference from Embodiment 1 is that: the support block 10 is a plate with a rectangular cross section; each group of support blocks 10 is connected to the corresponding synchronous belt 7; when the support block on the left synchronous belt 7 When 10 is located on the right side of the left synchronous belt 7, the upper left corner of the support plate 10 is transferred to the left synchronous belt 7; when the support block 10 on the right synchronous belt 7 is located on the left side of the right synchronous belt 7, the Board 10 upper right corners are transferred on the synchronous belt 7 on the right side.

[0021] When the plate 3 rises, the plate 3 can easily push the support blocks 10 above it away, so that the distance between the support blocks 10 can be smaller, and more plate 3 can be placed.

[0022] In the present invention, two sets of synchronous belt devices are adopted, and two sets of support blocks respectively arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com