Method and percussion bit for drilling back taper hole in concrete wall

A technology for concrete walls and impact drill bits, which is used in drilling/drilling equipment, components of boring machines/drilling machines, and drill repairs. Concrete hole friction and other problems, to achieve the effect of simple and practical method, easy to master and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

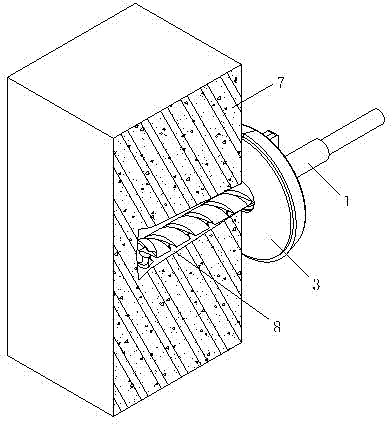

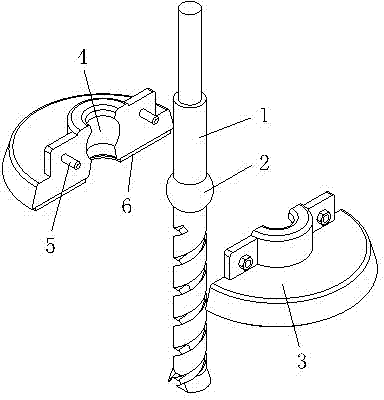

[0016] A kind of method of drilling inverted taper hole on the body of concrete wall of the present invention is, as figure 1 As shown, the method is to process a sphere on the shank of the impact drill, and then add a spherical clamp on the sphere, which is stuck on the sphere of the drill shank, and the drill shank can be rotated in the clamp with the center of the sphere as the fulcrum; When drilling, first drill the hole vertically to the wall. When the holder on the drill handle is against the wall, shake the drill handle to make the drill handle move with the center of the ball as the fulcrum, so that the bottom of the drill bit rotates at the bottom of the hole. The bottom is big and the upper part is small inverted taper hole. The spherical clamp has two semicircular structures, and the spheric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com