Hybrid Power Driving Module Possessing Motor

A hybrid power and drive module technology, applied in the direction of electric power devices, power devices, electric components, etc., can solve the problem that the hybrid power drive module is not optimal, and achieve the effects of long-term operation efficiency improvement, low cost, and improved cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

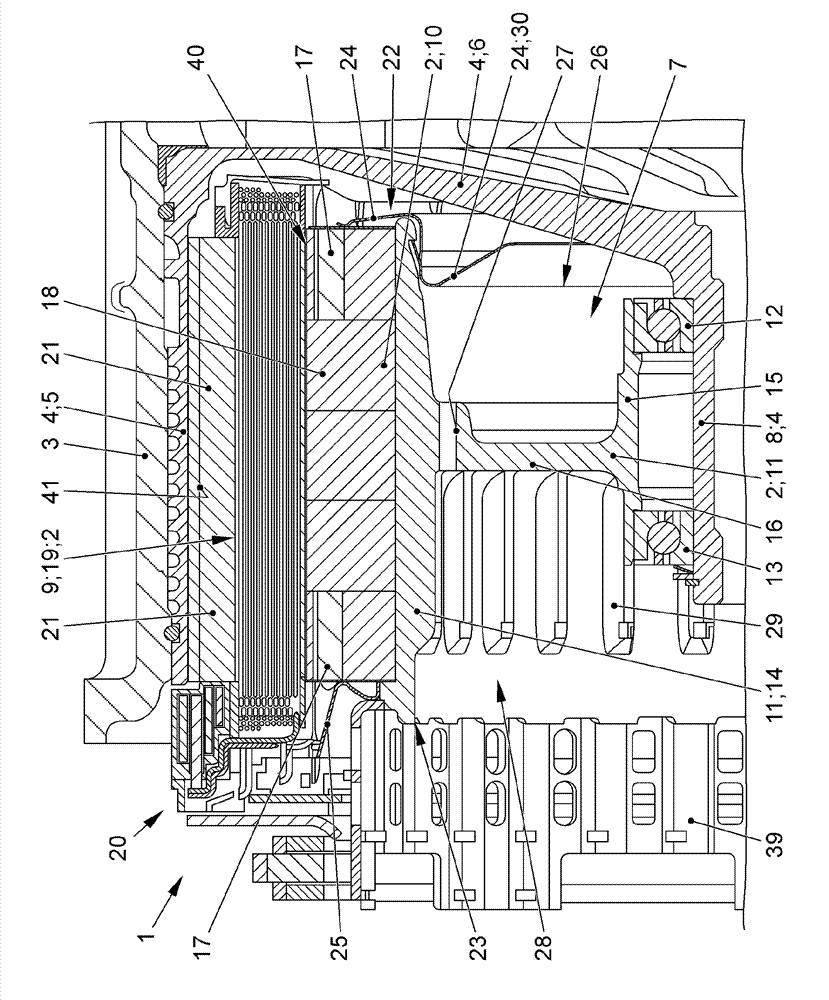

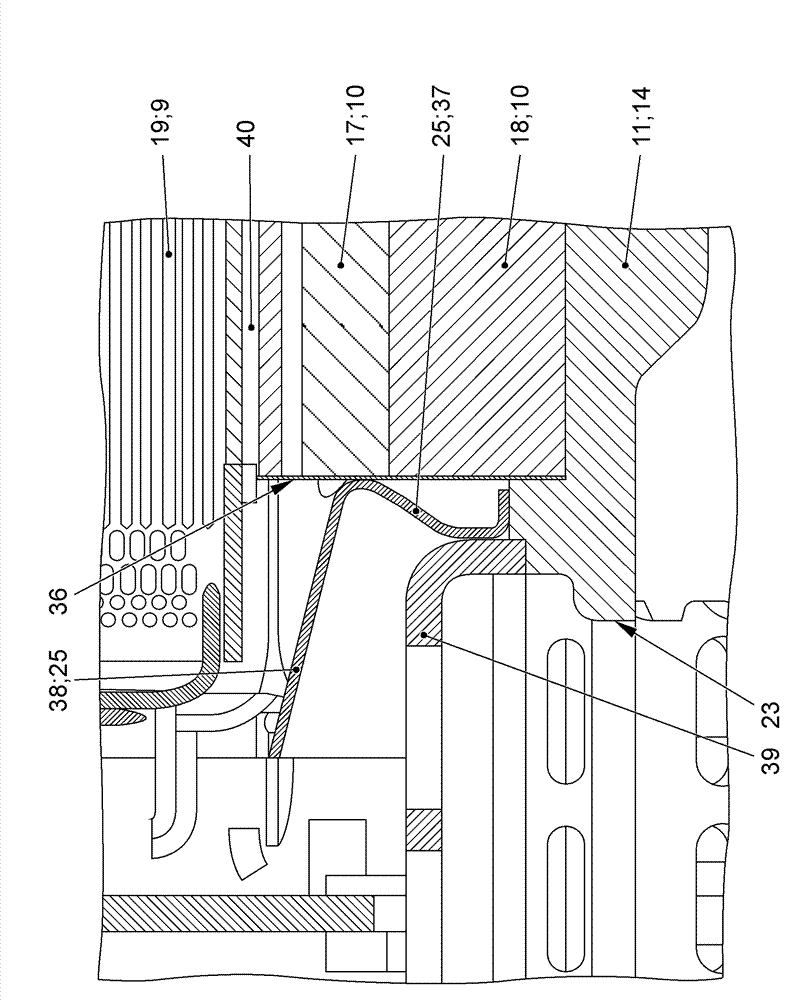

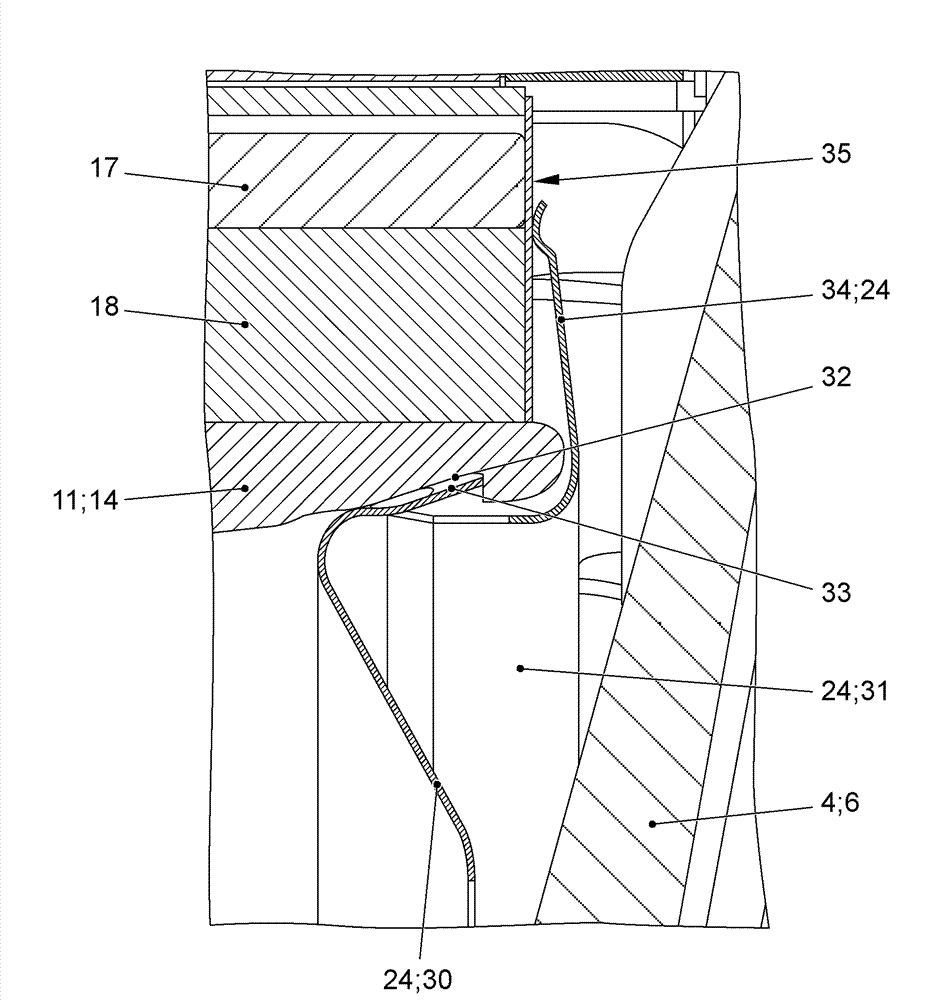

[0016] exist figure 1 The hybrid drive module 1 for the vehicle can clearly be seen in . The hybrid drive module 1 has an electric machine 2 . The electric machine 2 is arranged inside the clutch housing 3 . The electric machine 2 is also arranged inside a further inner housing 4 , the cooling housing. The housing 4 has a housing region 5 extending substantially in the axial direction. The housing region 5 serves here as a cooling housing. The side wall 6 extends inwardly adjacent to the housing region 5 . The housing 4 defines an oil chamber 7 , wherein the motor 2 is arranged inside the oil chamber 7 . The housing 4 also has a substantially hollow-cylindrical bearing region 8 . With its inner peripheral surface, the bearing region 8 delimits a shaft receptacle (not shown in detail), which is penetrated by a drive shaft (not shown). The bearing region 8 is here formed integrally with the side wall 6 and the housing region 5 . However, it should be noted that the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com