Device for separating spools with yarns from spools without yarns in spinning mill

A separation device and spinning mill technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of low labor efficiency, time-consuming and laborious, etc., and achieve the effect of avoiding duplication of labor and improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

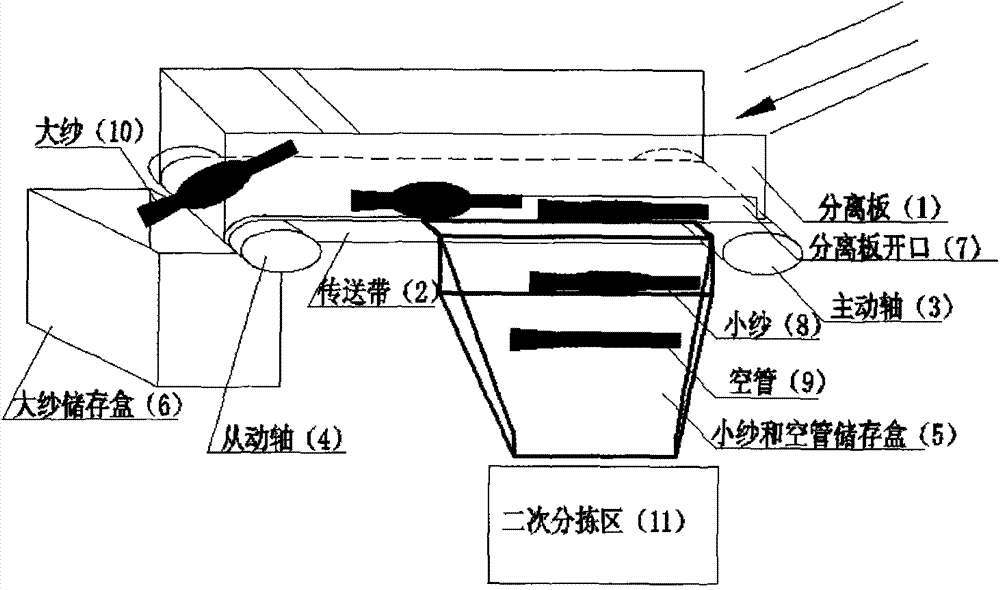

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] as attached figure 1 As shown, the technical solution includes a conveyor belt 2 driven by a driving shaft 3 and a driven shaft 4, a large yarn storage box 6 is arranged at the tail end of the conveyor belt 2, and a separating plate 1 is provided with a separating plate opening 7. One side of the separating plate opening is Small yarn and empty tube storage boxes 5 are arranged, the conveyor belt 2 forms an inclined angle with the horizontal plane, and one side of the separation plate opening 7 of the conveyor belt 2 is lower than the other side,

[0014] The opening 7 of the separating plate is set as a rectangular opening with a length of 300 mm and a width of 270 mm. When the ordered bobbins enter the conveyor belt 2 from the entrance, the angle between the driving shaft 3 and the driven shaft 4 and the horizontal plane is 17°. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com