Lifting method for frame bridge box body

A frame bridge and box technology, applied in the field of frame bridge box lifting, can solve the problems of destroying the integrity of the U-shaped groove, increasing the difficulty of construction, increasing costs and other problems, achieving remarkable advancement and practicability, and reducing construction. Difficulty and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The method for lifting the box body of the frame bridge provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

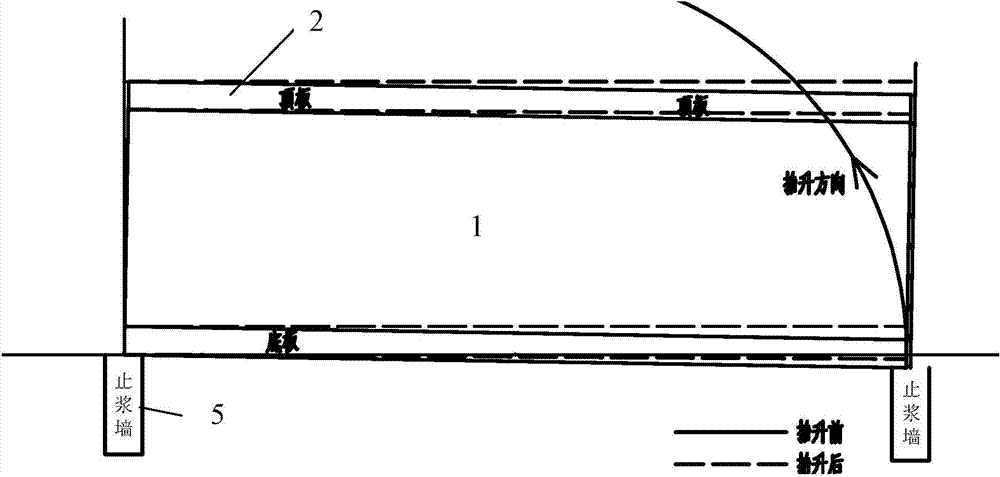

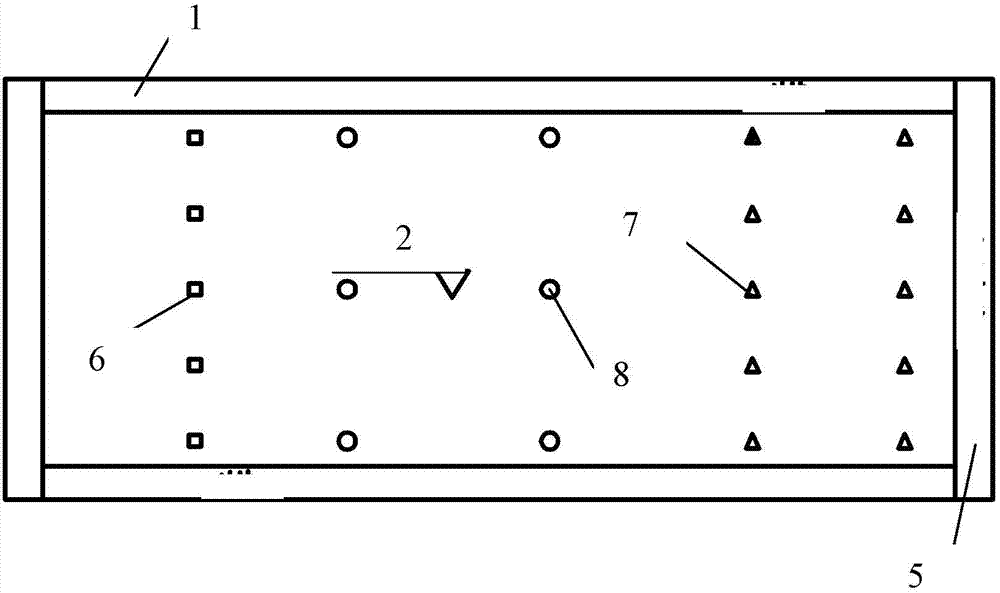

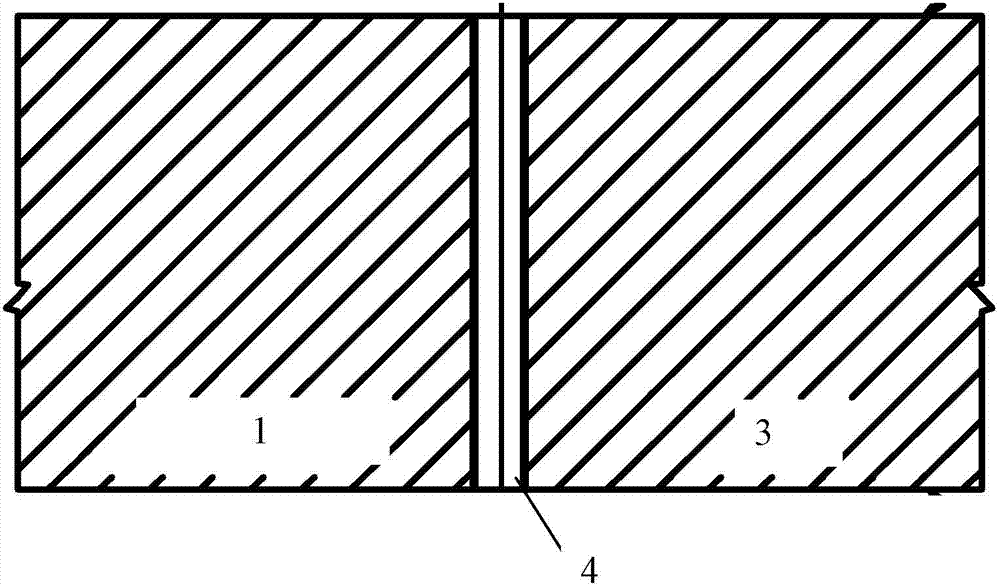

[0021] Such as figure 1 — image 3 As shown, the frame bridge box lifting method provided by the present invention includes the following steps carried out in order:

[0022] 1) Set an observation point at the four corners of the top plate of the box body 1, so as to observe the settlement when the box body 1 is raised;

[0023] 2) Mark the position of the steel bar within the range of the grouting hole on the bottom plate 2 of the box body 1, so as to stagger the position of the steel bar when drilling;

[0024] 3) Clean the settlement seam 4 between the bottom plate 2 of the box body 1 and the U-shaped groove 3 on both sides of the box body 1, and then use a water drill to drill down at this position and inject grout to make the U-shaped groove 3 is separated from the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com