Composite material floating type net-shaped interception system and construction method

A composite material and interception system technology, applied in the field of water collision avoidance structures, can solve the problems of poor weather resistance, difficult repair, and high cost of direct collision avoidance structures, and achieve superior mechanical properties, convenient installation, good weather resistance and resistance. Shock destructive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

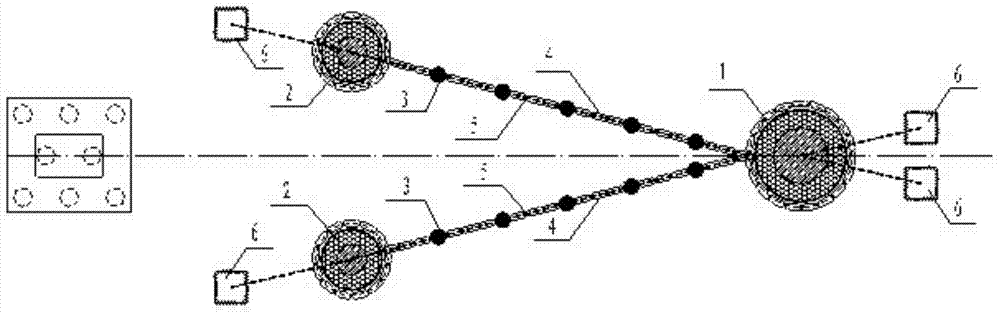

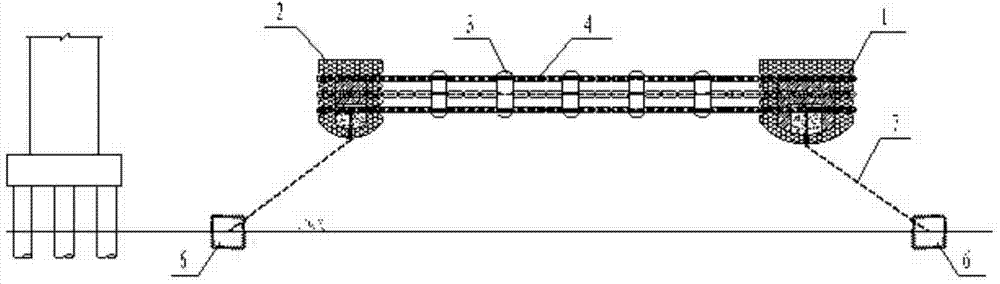

[0043] Such as Figure 1-7 As shown, a composite material floating mesh interception system includes main buoy 1, side buoy 2, secondary buoy 3, small buoy 4, cable 5, anchorage 6, ultra-high molecular weight polyethylene nylon cable 7, buffer energy consumption Material 8, buffer energy-dissipating space lattice body 9, concrete inner core 10 and buoy shell 13;

[0044] The main buoy 1 is connected to the two side buoys 2 respectively by two cables 5, a plurality of secondary buoys 3 are arranged at intervals on the cable 5, and a plurality of small buoys 4 are continuously arranged on the cable 5, and the main buoy 1 , side buoys 2, secondary buoys 3, small buoys 4 and cables 5 together form an intercepting net;

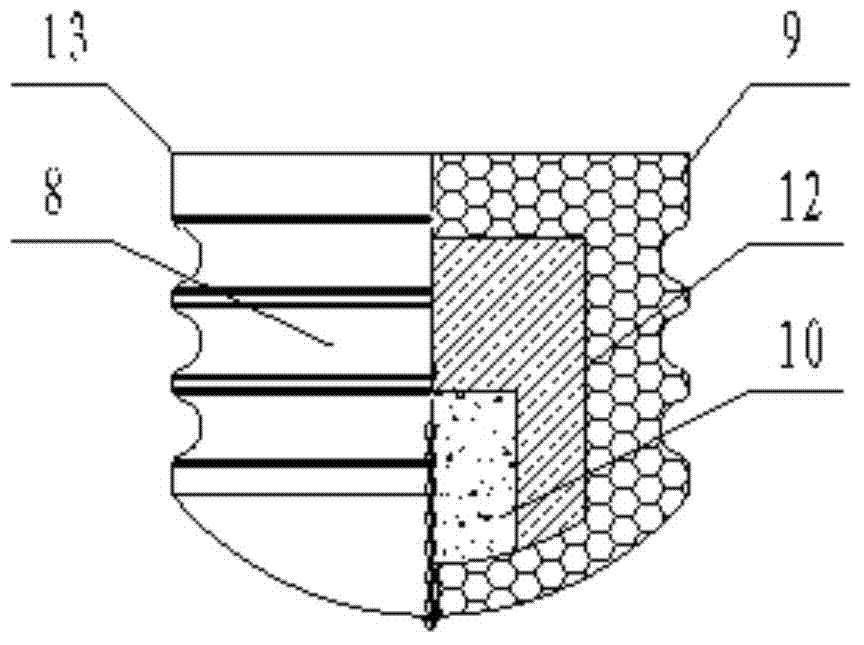

[0045] The main buoy 1, the side buoy 2, the secondary buoy 3 and the small buoy 4 are all made of composite materials, including a buoy shell 13 and a concrete inner core 10, and the buoy shell 13 is a solid shell composed of a composite material surface layer bod...

Embodiment 2

[0058] Such as Figure 8 with 9 As shown, this embodiment is basically the same as Embodiment 1, the difference lies in the arrangement of the anchors, and the main buoy 1 and the side buoys 2 respectively adopt the arrangement of three anchors 6 fixed in parallel.

Embodiment 3

[0060] Such as Figure 10 with 11 As shown, this embodiment is basically the same as Embodiment 1, the difference lies in the arrangement of the anchorage,

[0061] The main buoy 1 and the side buoys 2 respectively adopt the arrangement of three anchorages 6 fixed in series.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com