Energy-saving sandwiched insulation wall structure

A technology for thermal insulation of walls and walls, which is applied in thermal insulation, building structure, building thermal insulation materials, etc., and can solve problems such as condensation and mildew on indoor walls and unreasonable structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

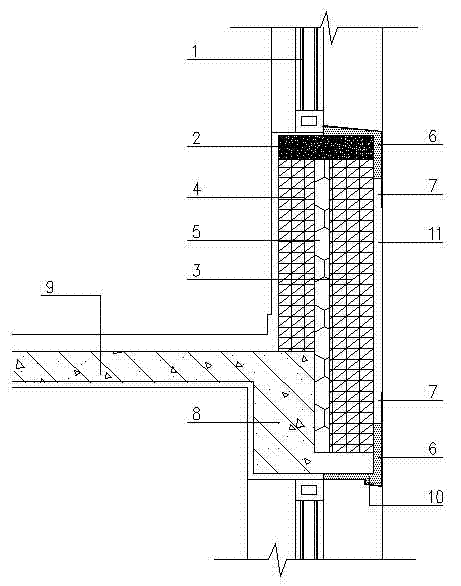

[0008] Such as figure 1 As shown, an energy-saving sandwich insulation wall structure, the outer wall masonry is MU5 light aggregate concrete block wall with a thickness of 180 mm, and the inner wall is a 90 mm thick MU3.5 light aggregate concrete block wall. The construction mortar is MMR5 ready-mixed mortar, the insulation layer is 50mm polystyrene foam board, and the thermal conductivity of the insulation board is 0.041K. There are reinforced concrete beams with a width of 250 mm and a height of 500 mm on the upper part. There are 230 mm wide and 100 mm high bumps under the reinforced concrete beams to support the thermal insulation material and the outer wall. 20 mm inorganic thermal insulation slurry, with mesh cloth outside the inorganic thermal insulation slurry, the length of the inorganic thermal insulation slurry is 100 mm longer than the concrete, the length of the mesh cloth is 200 mm longer than the thermal insulation mortar, and the mesh cloth is covered with 3 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com