Cast-in-situ fireproof and heat-insulating material for sandwich wall, and preparation method and application thereof

A technology for fire protection, heat preservation and sandwich wall, applied in the field of construction, can solve the problems of difficult control of assembly accuracy, low strength, low assembly efficiency, etc., and achieve the effect of improving toughness and strength, enhancing strength and hardness, and promoting uniformity and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A sandwich wall embodies a poured fireproof and thermal insulation material, comprising the following components in parts by weight:

[0045] Component A: 1 part of UPF resin, 0.01 part of polyethylene glycol, 0.03 part of Tween-80, gas phase SiO 2 0.05 part; The viscosity of described UPF resin is 200-400mPa·s;

[0046] Component B: NaHCO 3 0.05 parts, 0.05 parts of sodium lauryl sulfate, 0.1 parts of phosphoric acid;

[0047] The weight ratio of the A component to the B component is 1:1.

[0048] The above-mentioned cast-in-place fireproof and thermal insulation material can be applied to a sandwich wall as a thermal insulation layer, which includes the following steps:

[0049] (1) Weigh the raw materials of component A in proportion, stir evenly to obtain component A, weigh the raw materials of component B in proportion, and stir uniformly to obtain component B;

[0050] (2) Mix components A and B evenly, foam for 5-10 minutes, pour into the prefabricated wall...

Embodiment 2

[0052] A sandwich wall embodies a poured fireproof and thermal insulation material, comprising the following components in parts by weight:

[0053] Component A: 1 part of UPF resin, 0.04 part of polyethylene glycol, 0.05 part of Tween-80, gas phase SiO 2 0.1 part; the viscosity of the UPF resin is 200-400mPa·s;

[0054] Component B: NaHCO 3 0.1 part, 0.12 part of sodium lauryl sulfate, 0.15 part of phosphoric acid;

[0055] The weight ratio of the A component to the B component is 1:1.2.

[0056] The above-mentioned cast-in-place fireproof and thermal insulation material can be applied to a sandwich wall as a thermal insulation layer, which includes the following steps:

[0057] (1) Weigh the raw materials of component A in proportion, stir evenly to obtain component A, weigh the raw materials of component B in proportion, and stir uniformly to obtain component B;

[0058] (2) Mix components A and B evenly, foam for 5-10 minutes, pour into the prefabricated wallboard, l...

Embodiment 3

[0060] A sandwich wall embodies a poured fireproof and thermal insulation material, comprising the following components in parts by weight:

[0061] Component A: 1 part of UPF resin, 0.02 part of polyethylene glycol, 0.04 part of Tween-80, gas phase SiO 2 0.08 part; The viscosity of described UPF resin is 200-400mPa·s;

[0062] Component B: NaHCO 3 0.08 parts, 0.06 parts of sodium lauryl sulfate, 0.12 parts of phosphoric acid;

[0063] The weight ratio of the A component to the B component is 1:1.

[0064] The above-mentioned cast-in-place fireproof and thermal insulation material can be applied to a sandwich wall as a thermal insulation layer, which includes the following steps:

[0065] (1) Weigh the raw materials of component A in proportion, stir evenly to obtain component A, weigh the raw materials of component B in proportion, and stir uniformly to obtain component B;

[0066] (2) Mix components A and B evenly, foam for 5-10 minutes, pour into the prefabricated wal...

PUM

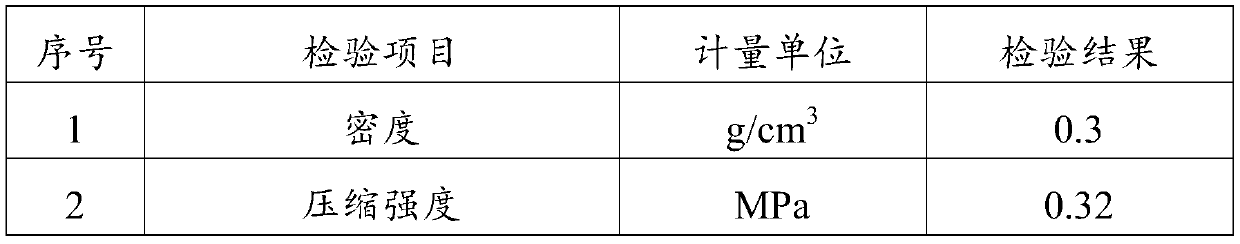

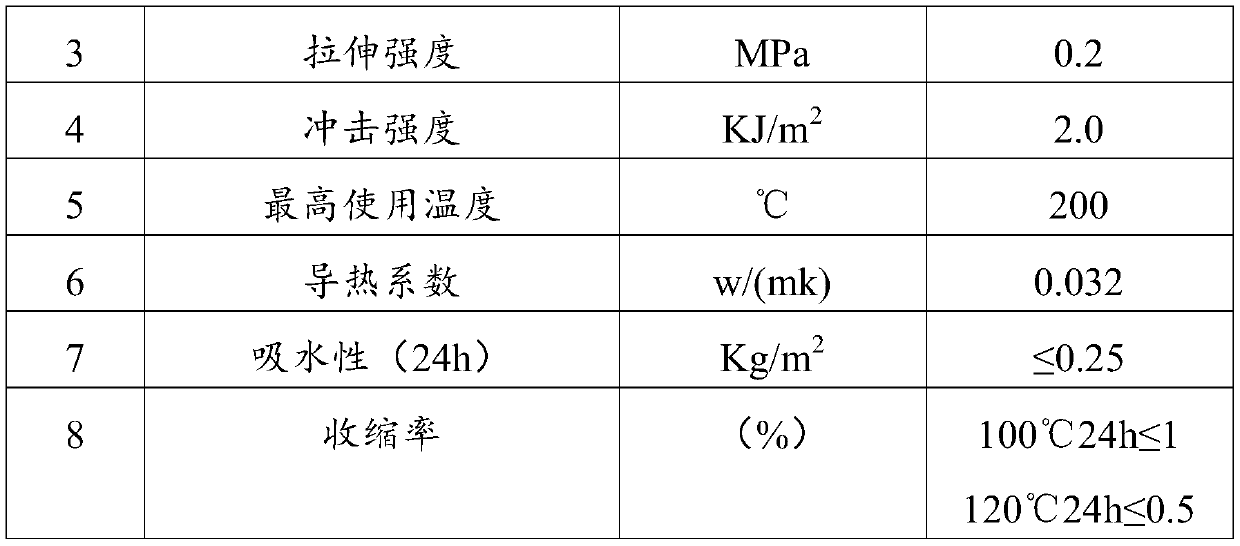

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com