Heavy-load conical hinge

A conical and hinged technology, applied in hinges with pins, door/window fittings, folding boards, etc., can solve the problems of easy corrosion and noise of metal parts, and achieve easy installation and maintenance, simple structure, and easy manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

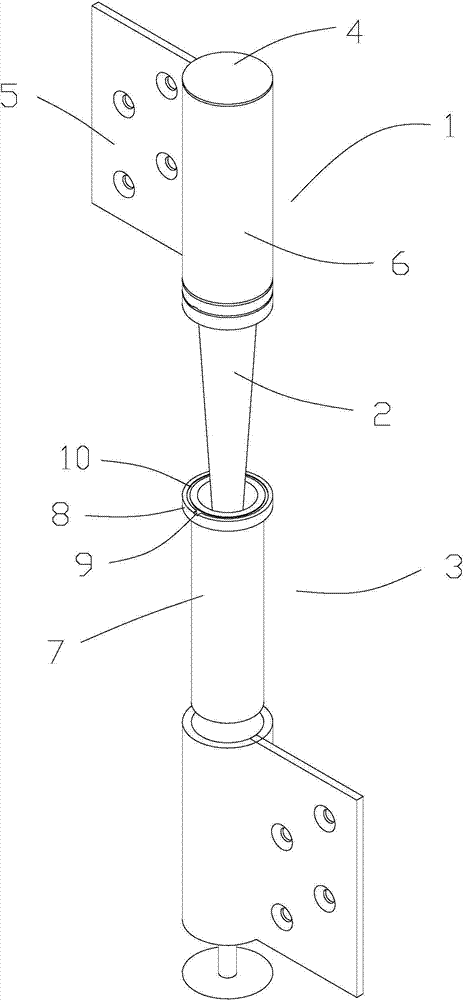

[0029] see figure 1 , in order to facilitate the display of the product, and in view of the symmetry of the product structure, figure 1 Only the lower half is shown for splitting. This embodiment discloses a heavy-duty conical hinge, which includes two mutually hinged discs 1, a conical hinge pin 2, a nylon pin sleeve 3 and a pin cap 4;

[0030] Each disc 1 includes a sheet-shaped disc body 5 and a connector 6; the disc body 5 and the connector 6 are integrally formed, and the connector 6 is connected to the side of the disc body 5; the disc body 5 is provided with At least two counterbores; the connecting piece 6 is provided with a through hole along the axial direction;

[0031] The conical hinge pin 2 has a double-conical structure with a wide middle part and narrow ends. The middle part of the conical hinge pin 2 is provided with a cylindrical radially outwardly protruding annular part, and the outer diameter of the annular part is equal to the outer diameter of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com