Magneto-rheological torsion damper of clutch and clutch with same

A torsional shock absorber and clutch technology, applied in clutches, shock absorbers, friction clutches, etc., can solve problems such as uncontrollable damping parameters, and achieve the effects of compact structure, low energy consumption and reasonable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

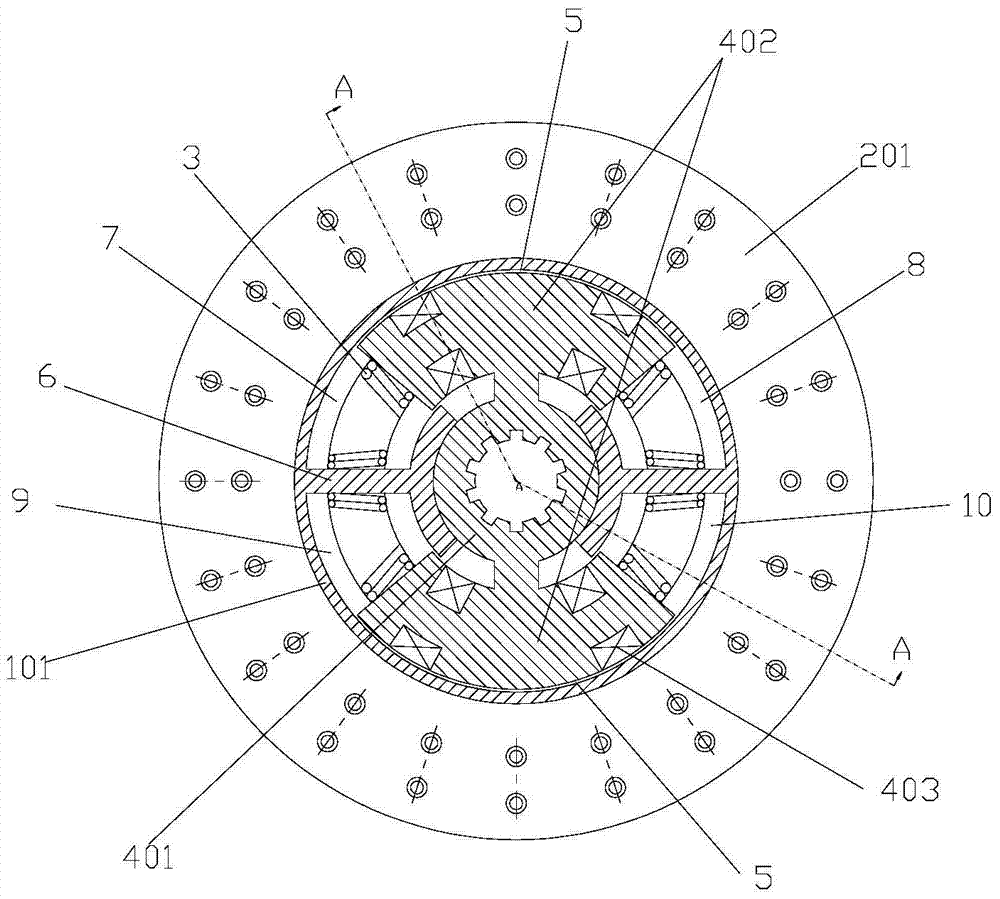

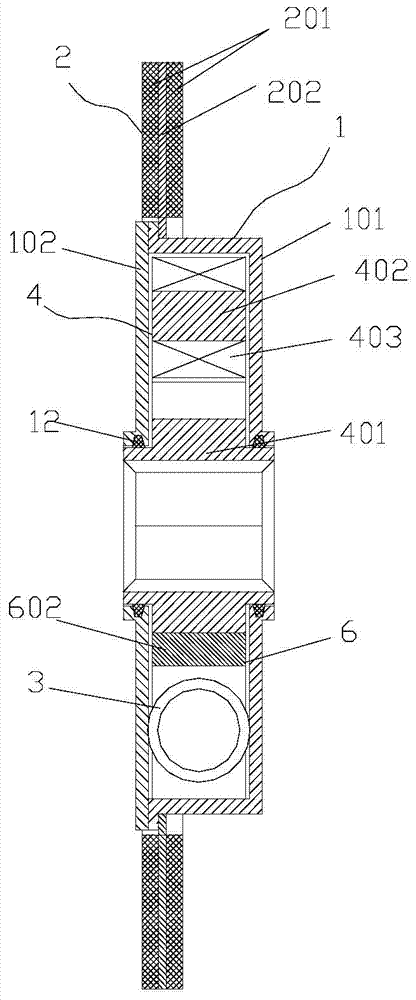

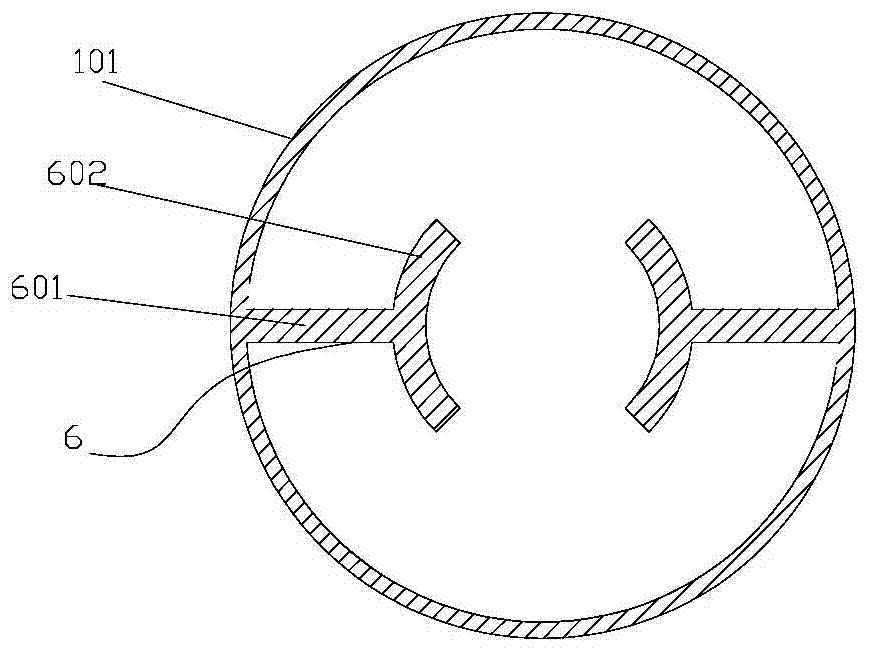

[0019] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 A-A schematic diagram of the structure, image 3 It is a schematic diagram of the sleeve structure of the present invention, Figure 4 It is a structural schematic diagram of the magnetorheological damping device of the present invention, as shown in the figure: the clutch magnetorheological torsional shock absorber of this embodiment includes a sleeve 1 with a cavity inside and is fixedly connected with the sleeve 1 and input torque The torque input part 2 also includes an elastic damping element 3 that can be elastically compressed to buffer vibration when the torque is input, and a magnetic flow that performs circular rotation in the cavity to generate magnetorheological damping force under the force transmission of the elastic damping element 3 The variable damping device 4 is filled with a magneto-rheological fluid medium in the cavity; wherein, the sleeve 1 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com